Starting Out: Water

Continuing the IChemE National Early Careers Group series profiling early career opportunities in different sectors

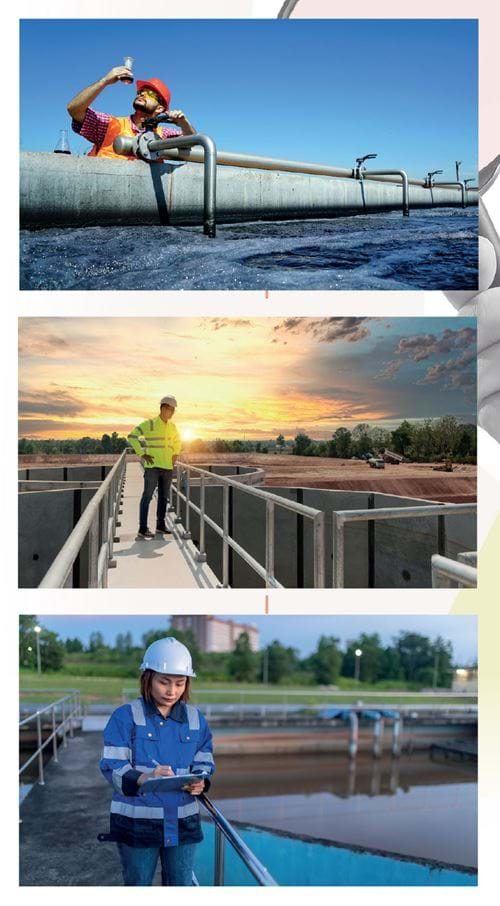

WATER is rarely thought of as a resource that requires processing. Yet making drinking water safe, treating wastewater for environmental release and recovering valuable bioresources all demand complex processing – and thus significant chemical engineering. With all these problems to solve and the regulator recently approving record funding, there has never been a better time to work in the water industry. To learn more about the opportunities in water today, Orla Douds caught up with three young engineers in the industry.

Could you describe the career path that led to your current role?

Shirley Cheng

Process engineer at Stantec

I completed an MEng in Chemical Engineering with an industrial placement at the University of Bath.

During my degree, I completed my year-long industry placement with Uniper as an undergraduate operations and maintenance engineer at a CCGT gas-fired power station. I also completed my semester-long research project (as part of my integrated master’s) on freeform 3D printing vascular networks abroad in Singapore at Nanyang Technological University.

After university I joined Stantec on their graduate scheme as a graduate process engineer. I found the role through LinkedIn and completed my application through Stantec’s career website. The graduate scheme was two years and I was then promoted to process engineer.

Stephanie Hallam

Water treatment scientist at Severn Trent

I started my career studying an MEng in Chemical Engineering at the University of Birmingham where I learnt a breadth of skills covering a range of engineering topics; from more traditional engineering such as fluid dynamics and process control to renewable energy systems and frontiers in tissue engineering. During my research project, I found a love for research, discovery and innovation and decided to embark on the four-year journey of completing a PhD. My PhD focused on the development on an in vitro model of microvascular collapse to aid in diagnosis of acute compartment syndrome. This included detailed analysis of fluid dynamics using particle tracking techniques in deformable systems and creating validated, complimentary CFD models to maximise their potential. Following this I entered industry, working as a water treatment scientist at Severn Trent, combining skills I had learnt throughout my education to improve plant performance.

Alex Hare

Graduate process engineer at United Utilities

I did a master’s in chemical engineering at the University of Birmingham and graduated in 2023. In my final year I applied for various process engineering roles in the northwest and was offered a role on the process engineering graduate scheme at United Utilities.

Could you describe your current role?

Shirley: I am a process engineer in the water team at Stantec, a worldwide engineering consultancy company. Over the last three years, I have worked on a range of water, wastewater and bioresources projects for water utilities across the UK.

As I work for an engineering consultancy, I am typically desk based. Each day is different as it is dependent on the projects I am working on. My experience includes conducting mass balances on water treatment works, designing and sizing the odour control units required for a new anaerobic digestion site and completing carbon assessments on a sludge treatment centre to aid in reducing fugitive emissions.

Despite my role being desk based, I do go onto the client’s sites. Past site visits have included water treatment works, wastewater treatment works and sludge treatment centres. Typically, the site visits consist of a non-intrusive site survey and getting the required drawings, pictures and information. However, sometimes the site visits are for more practical reasons, such as sampling.

Stephanie: Not one to sit still, my current role as a water treatment scientist at Severn Trent stood out to me for the variation and breadth of possibility. No two days are the same. I am often based on site at the water treatment works, working both in the office and on site. However, I regularly attend training courses through the academy and at sites across the Severn Trent region. I have also visited our biology and microbiology labs, pilot plants and CFD space. In my role, I review and recommend changes across the process plant for optimisation and performance purposes and conduct investigations, both in the lab and numerically, for improvement schemes.

“Whilst it seems like water is an infinite resource, if we don’t ensure we sufficiently treat drinking water and wastewater, it may become more finite than infinite.”

Shirley Cheng

Alex: I’m a graduate process engineer at United Utilities, which provides water and wastewater services across the northwest of England. As part of the graduate scheme, I’ve had the opportunity to rotate across different areas of the business, at both the head office and on operational sites.

Currently, I’m working on the process commissioning of a new biological treatment system at a wastewater treatment plant in Cheshire. This will replace the existing process to provide higher quality effluent, improving water quality in the river that the site discharges to. My role involves hands-on operational tasks to check the plant is working as intended, as well as desk-based activities such as data analysis and technical report writing. This all comes together to support optimisation of the new process, helping it to perform efficiently and meet environmental standards.

What do you think of the water industry and do you think you’ll stay in it?

Shirley: I think that this industry is particularly important since clean water is a necessity and there is and always will be, waste to treat. Furthermore, there are three UN Sustainable Development Goals (SDGs) directly related to water. Providing safe water supplies and effective wastewater treatment is central to SDG 6, clean water and sanitation. Effective wastewater treatment also aids in preventing pollution and protects aquatic ecosystems, directly supporting SDG 14, life below water. Similarly, responsible sludge and wastewater management will help to protect soils and land, contributing to SDG 15, life on land.

Additionally, whilst it seems like water is an infinite resource, if we don’t ensure we sufficiently treat drinking water and wastewater, it may become more finite than infinite.

I have particularly enjoyed working in bioresource projects, specifically energy generation from waste, as I find it fascinating. It’s also great to see what novel solutions there are in treating wastewater and generating energy from that waste.

Stephanie: Water will always be needed. I think that in itself gives the industry a sense of stability. Although it is somewhat at the mercy of the elements in our ever-changing climate there will always be demand and therefore there will be problems that have to be solved. As a problem solver I can’t see myself ever getting bored.

Alex: Although the water industry isn’t always the first area that comes to mind for chemical engineers, I’ve found it to be both technically interesting and rewarding. I value the purpose of the work as it directly benefits the public and the environment by providing clean drinking water and improving river quality.

There’s still a lot of progress to be made in areas such as decarbonisation, including reducing chemical usage, lowering process emissions and improving energy efficiency. These are challenges that I’m keen to help address, which is why I can see myself staying in the water industry long-term.

What advice would you give to a recent graduate or early careers chemical engineer who wants to work in the water industry?

Shirley: Take every opportunity you can take to learn and develop, and do not be afraid to ask questions. I know it’s such cliche advice but there really is no silly question! I’ve found in water particularly, there are so many acronyms and they sometimes differ between water utilities. Also, each water utility has different design standards, so it’s always good to double-check if you’re unsure.

Stephanie: Be curious! There is a lot to learn when you enter a new role and it is important to speak to everyone and learn as much as you can. Talk to operators on the front line – their firsthand knowledge is incredibly valuable – as well as the engineering team. Don’t just learn the what but the why and the how, too.

Alex: As with any industry it’s important to research key technologies and how the sector operates. This will help with deciding if it’s something you’re interested in and gives a strong foundation for interviews. Working on site and getting practical experience in a role will really help with development and understanding.

Useful resources

- TCE: The Challenges of Eliminating Nitrous Oxide from the Water Sector: https://bit.ly/tce-water-challenges

- IChemE’s Water Special Interest Group: bit.ly/icheme-water-sig

- Companies working in the water sector with IChemE Accredited Company Training Schemes (ACTS) include: Galliford Try, Scottish Water and United Utilities. Find more info here: www.icheme.org/acts-schemes

Orla Douds AMIChemE is a process engineer at Assystem and article lead for IChemE’s National Early Careers Committee

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.