The Challenges of Eliminating Nitrous Oxide from the Water Sector

Nitrous oxide emissions from water resource recovery facilities have long been under-estimated say Amanda Lake, Aprilia Vellacott, and Liu Ye. Reducing them offers an opportunity for chemical engineers to make a real difference

IT STARTS with the food we eat. Whether directly, through plant proteins in legumes which produce their own nitrogen fertiliser, or indirectly, through the protein intake of animals we may choose to eat. A fraction of this protein is nitrogen, and this is excreted daily by us all – something like 12.5 g of nitrogen per person per day into our sewerage networks and along to our wastewater treatment or water resource recovery facilities (WRRFs).

When we biologically treat wastewater as is our current practice, a fraction of this nitrogen produces nitrous oxide (N2O), a long-lived, potent greenhouse gas with 273 times the global warming potential of CO2.1 We report these emissions as a mass emission of CO2 equivalent (CO2e) and as an “emission factor” – typically reported as a percentage of incoming nitrogen which is emitted as nitrous oxide.

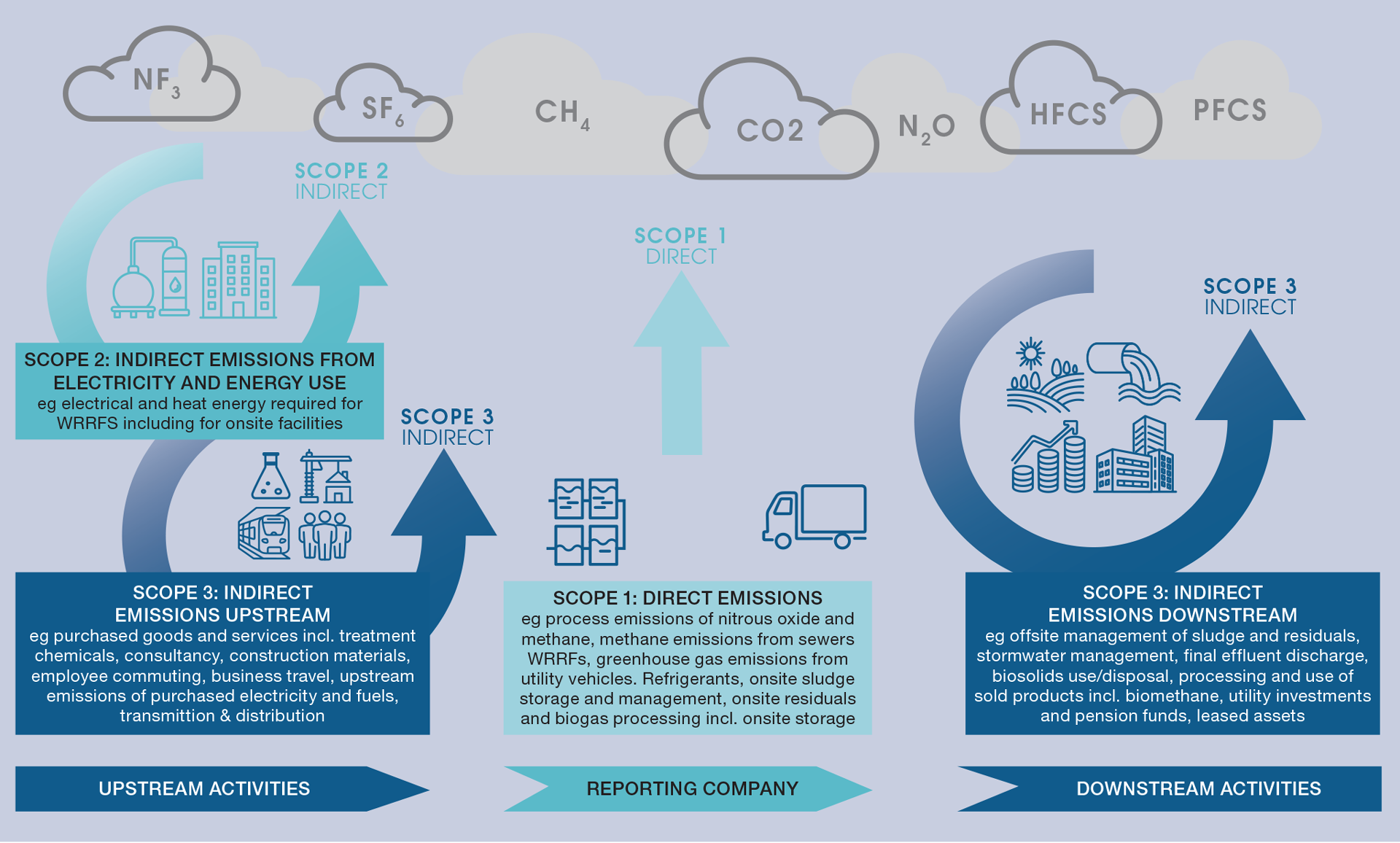

Along with methane (CH4) emissions, these greenhouse gases are termed process emissions (also known as direct Scope 1 process or fugitive emissions), which are directly emitted from wastewater treatment processes in industrial and municipal WRRFs. Both gases have immediate negative impacts beyond planetary heating – methane contributes to localised air pollution and nitrous oxide also destroys ozone. As the sectors that produce the power, concrete, steel, and chemicals used in wastewater treatment plants decarbonise their operations, the wastewater sector’s own direct process emissions will come to dominate the industry’s emissions.

Indeed, the UN-Water Expert Group on Water and Climate Change highlighted the importance of the water sector in the climate change mitigation at their technical workshop at the margins of the Bonn Climate Conference in 2023. The group’s output report, Water and Climate Change Inter-Dependencies, which our team contributed to, highlighted the importance of reducing greenhouse gas emissions of nitrous oxide and methane from WRRFs.2 It reported that methane from wastewater treatment is estimated at some 7–12% of global methane emissions, while nitrous oxide emissions from wastewater treatment may be 3–4% of total global nitrous oxide emissions. Nitrous oxide emissions are recognised as highly significant in WRRF footprints – potentially comprising up to three-quarters of the overall carbon footprint of WRRFs. While methane production and mitigation within WRRFs is relatively well understood, nitrous oxide production, emissions, and mitigation options are less well known – though we stress that sufficient is still understood to be able to act on these today.

Nitrous oxide emissions from WRRFs

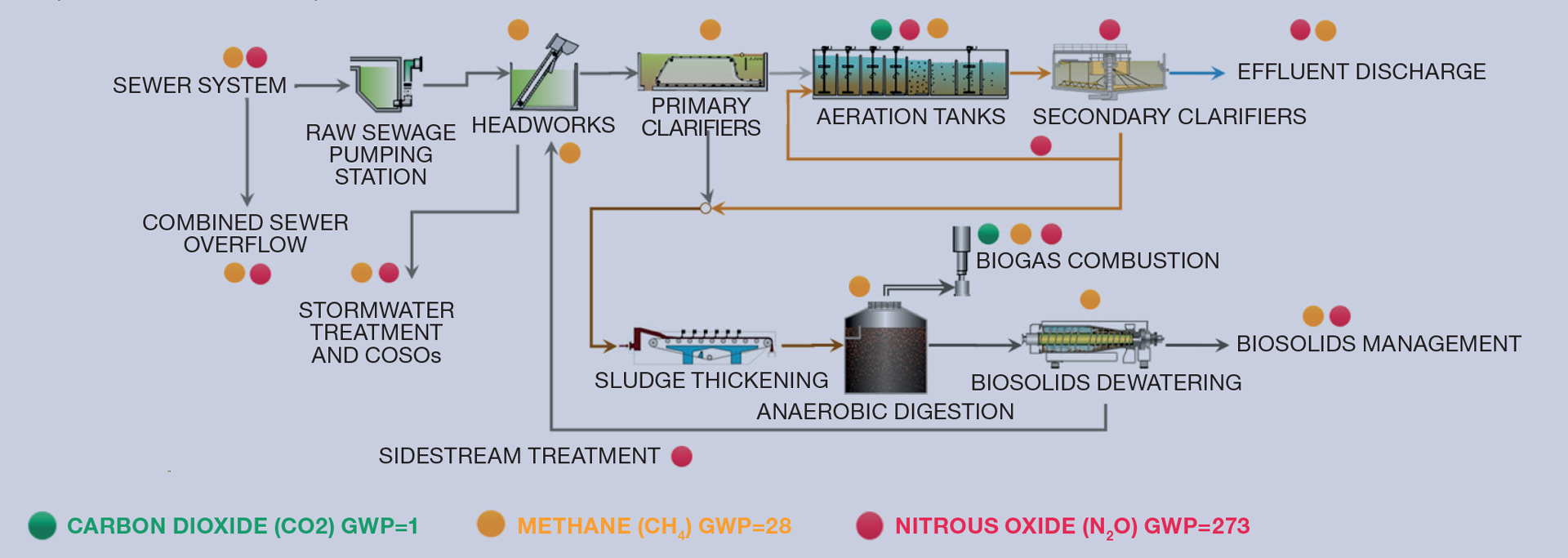

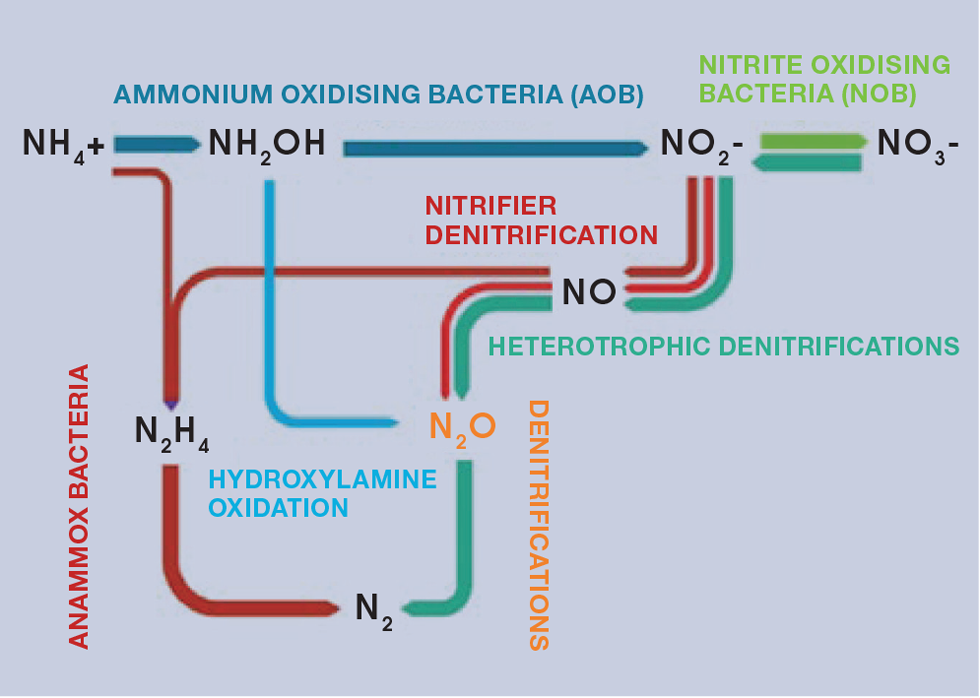

During the biological treatment of wastewater, nitrous oxide emissions are released – from secondary aerobic and anoxic treatment, liquors treatment, and in the management of biosolids and combined sewer overflows. Residual nitrogen released to the environment may form nitrous oxide (to a greater extent in nutrient-polluted water bodies) and dissolved nitrous oxide may also be released. Figure 1 shows these key emission sources (along with other key greenhouses gases methane and CO2) and Figure 2 the known biotic and abiotic pathways. Other treatment technologies, for example incineration and advanced thermal treatment of sludges, are also large potential sources of nitrous oxide emissions.

Known (though simplified) biological pathways for nitrous oxide production and reduction are shown in Figure 3. In WRRFs, three known biological production pathways exist along with one nitrous oxide reduction pathway or sink as part of the denitrification process. WRRFs which remove total nitrogen and include denitrification are recognised as having the potential for lower potential nitrous oxide emissions – a synergy where improved effluent quality with lower total nitrogen may also have environmental benefits.

Nitrous oxide is understood to be produced when process conditions for biological transformation are sub-optimal, and processes may be unstable or variable. Chemical engineers are leading much of the work to overcome these issues. This includes developing and refining monitoring methods and applying process engineering to analyse process data and draw insights. Chemical and process engineers are developing and adopting digital tools and modelling approaches to help quantify the problem and optimise process design and control.

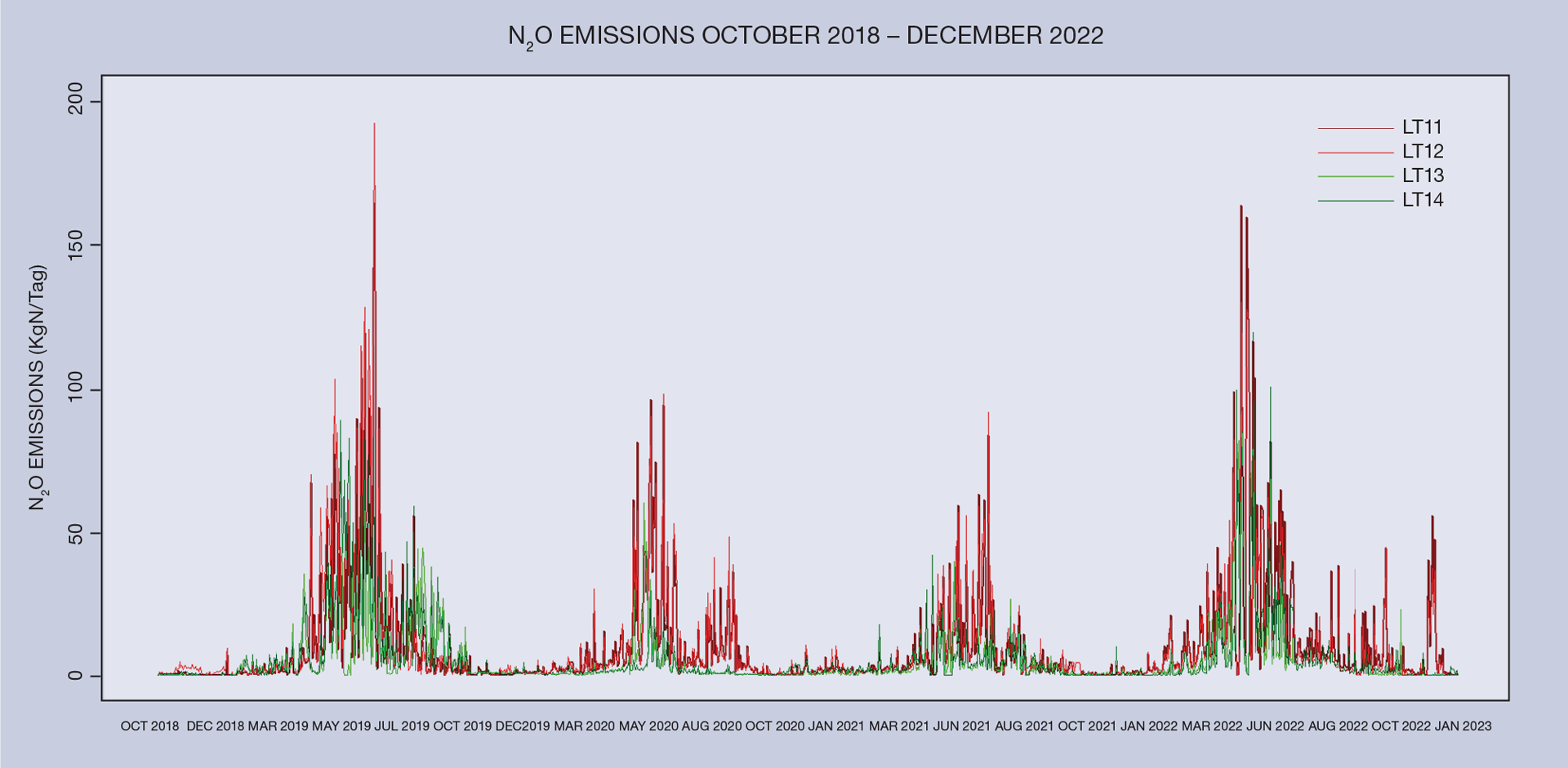

A key challenge is that nitrous oxide emissions from WRRFs are highly variable – even from WRRF to WRRF – and dependent on monitoring locations, seasons, and operational factors which can greatly impact on both nitrous oxide production and emissions. Water utilities are waking up to these issues, however, with the collaborative Global Water Research Coalition and recent work in Dutch, Swiss, German, Danish, New Zealand, French, Australia and UK water sectors highlighting the importance of national measurement campaigns and the development of in-country emissions factors for more accurate reporting.

In 2019, the Intergovernmental Panel on Climate Change (IPCC) published new guidance in the 2019 Refinement to the 2006 IPPC Guidelines. The updated Guidelines recognised that nitrous oxide emissions from WRRFs are significant and increased the previously optional emission factor for quantifying nitrous oxide from WRRFs from 0.05% to a recommended 1.6% of influent total nitrogen load – a substantive change based on evidence from 29 global studies. This change significantly increased estimated emissions from WRRFs, recognising that these emissions are not negligible and in fact are extremely significant (for some utilities these will comprise up to 80% of their reported greenhouse gas footprints). Unfortunately, the new emission factor for nitrous oxide in the 2019 revision has yet to be adopted for global national reporting by member states under the Paris Agreement. There are a few exceptions, however (well done Canada and the US!).

Significant additional evidence from long-term measurement studies of nitrous oxide emissions has been published – with new national emission factors having been developed for Denmark (0.84%) and Switzerland (1.8% for nitrifying WRRFs, 4.3% for carbonaceous WRRFs, and 0.8% for nitrifying/denitrifying WRRFs). France also has emerging guidance for particular treatment process types.3 This work has highlighted that facility level measurement is critical – one emission factor will not support accurate baselining and, most importantly, mitigation which needs to happen WRRF by WRRF.

Another key challenge is that standard measurement methodologies are lacking. While setting out a new tiered approach which highlights the importance of moving towards advanced methods for measurement of emissions at “tier 3” facility level, the IPCC guidelines do not provide guidance on how to do this. Any regulation which may drive this is lacking in all but a few countries – a recent proposal for regulation (Denmark) and existing offsetting programmes (Switzerland) incentivising action to reduce nitrous oxide and resulting in the development of standard approaches.

The UK water sector has published an industry report providing an overview of measurement methods and best available guidance; while the new Danish regulatory proposal also includes requirements for nitrous oxide monitoring. Recent rapid evidence assessments (REA) for the UK Department for Environment, Food and Rural Affairs (DEFRA) provide current evidence for measurement and mitigation and recommended focus areas for research and innovation funding to improve the UK greenhouse gas inventories for both municipal and industrial wastewater with respect to process emissions of nitrous oxide (and methane).

However, best practice is yet to be well established – liquid and gas phase measurement approaches can both yield very useful results, particularly when complimented by high quality process data including throughout the WRRF and within treatment zones. Instrumentation requirements to best understand nitrous oxide production and emission remain onerous in this global learning phase. We are often reminded that once upon a time WRRFs did not have dissolved oxygen probes, but these are now standard. In our time of climate crisis, we are hopeful that monitoring for nitrous oxide will be standard one day soon, too.

Process data availability and quality and the accuracy of process instruments is key. This includes accuracy of existing liquid and gas phase analysis of nitrous oxide auxiliary data such as process air flows. Other process data – dissolved oxygen concentrations, nitrogen species, perhaps molecular data about biological communities treating our wastewater – is also likely to be required to understand how nitrous oxide is produced and emitted. Chemical engineers have an important role in understanding these issues to design and execute effective measurement campaigns which allow quantification, prioritisation, and mitigation.

The role of process engineers ranges from visual analysis of the system operation during periods of nitrous oxide production through biokinetic modelling, hybrid and machine learning methods which may be used for quantification and exploration of mitigation possibilities. The aim is to achieve low nitrous oxide system outcomes while maintaining effluent quality at lowest possible energy input.

These approaches remain evolving (and exciting!). Quantifying observed seasonal dynamics using models of any sort and the role of high-quality data and additional analysis of parameters historically not of interest are now focus areas. This will require improved understanding and measurement of process intermediates such as nitrite which have been shown to play a key role in nitrous oxide production – and molecular methods to better understand microbial communities.

Reducing nitrous oxide emissions

Solutions are available today to reduce nitrous oxide emissions, however, and we must be inspired by these. For example, work in Denmark has demonstrated 48–74% reductions in emissions at Copenhagen’s Avedøre Wastewater Treatment Plant, the second largest facility in the country. This was achieved by implementing a higher mixed liquor suspended solids setpoint (+0.5 g/L) during winter (see Figure 5).

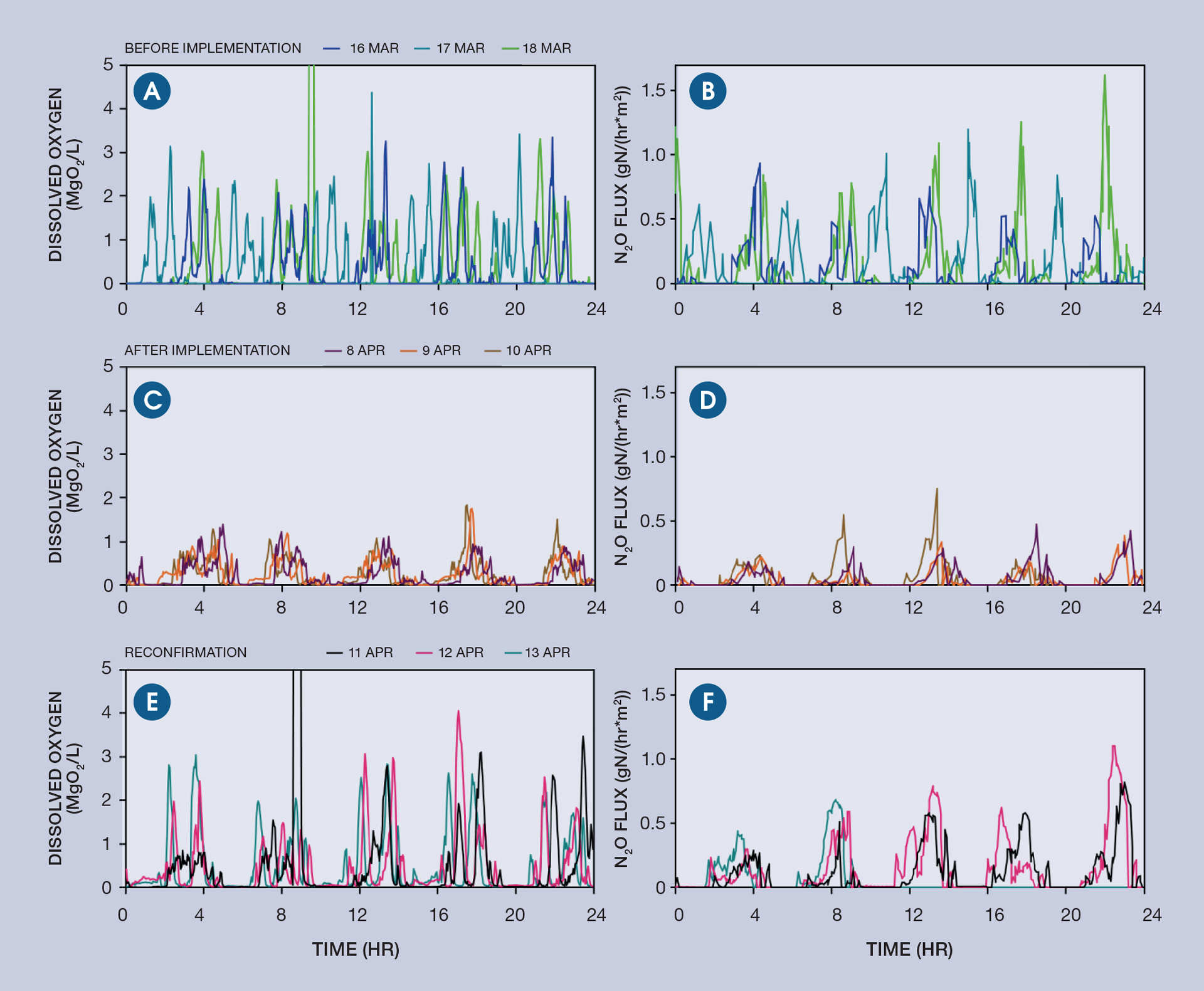

In another full-scale mitigation case study, a 35% nitrous oxide reduction was achieved at South Australia’s Bolivar WRRF after a low dissolved oxygen mitigation strategy was implemented. Figure 6 provides data from the dissolved oxygen concentration and emitted nitrous oxide flux before and after the implementation of the strategy. During a reconfirmation period, the mitigation strategy was switched off and dissolved oxygen levels (see Figure 6E) reverted to back to the levels in Figure 6A. Higher nitrous oxide emissions seen in 6A were again observed (6F) versus those during mitigation (see Figure 6D).

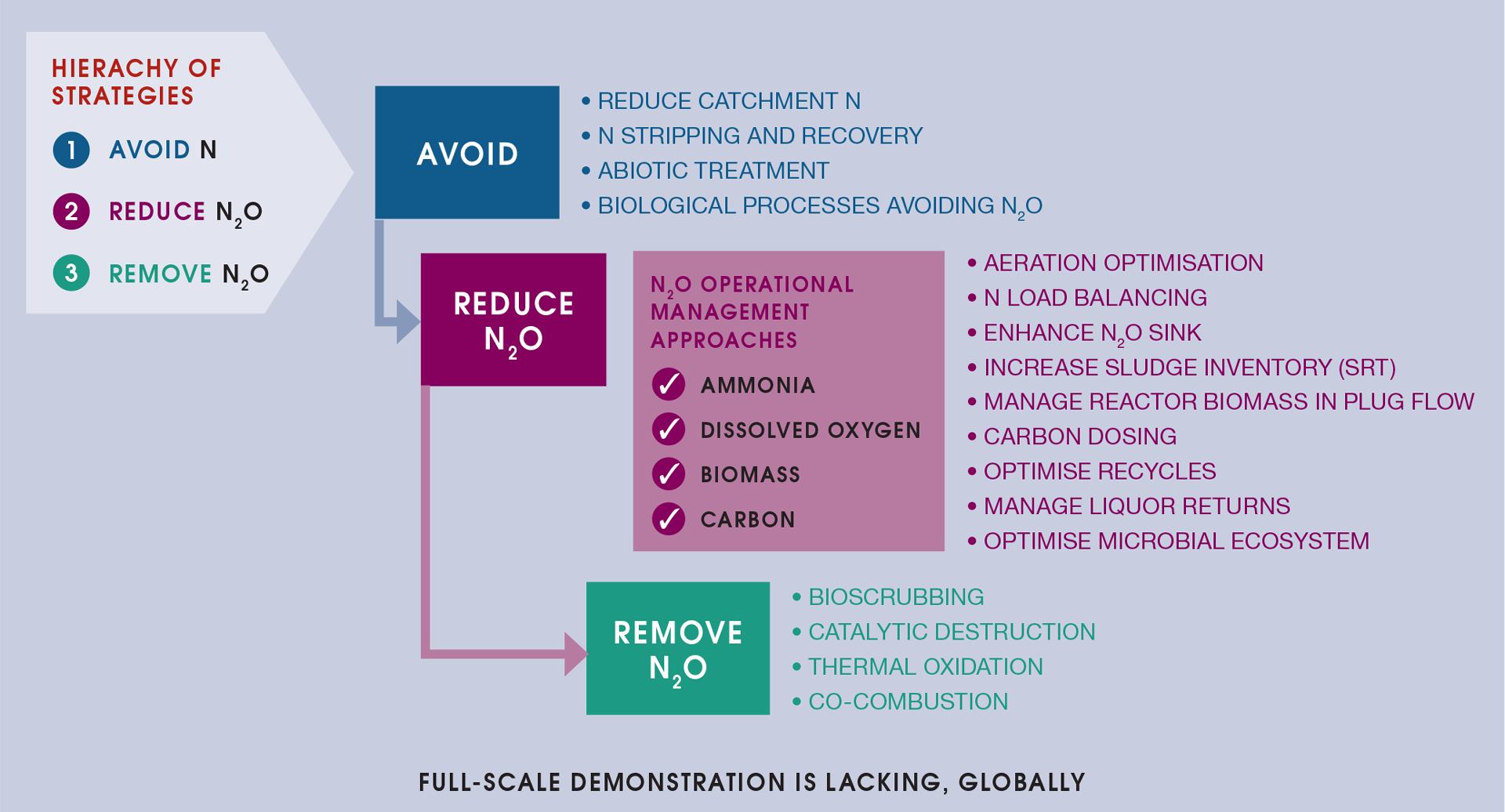

Mitigation of nitrous oxide is possible, but industry drivers are lacking

Existing evidence supports mitigation strategies which are focused on a number of areas as shown in Figure 7 – with key areas of focus, the optimisation of WRRFs, destruction of nitrous oxide, technology solutions which produce less nitrous oxide, opportunities to capture and treat resultant nitrous oxide and recovery of nitrogen to prevent nitrous oxide formation in the first place. Research into microbial communities which produce less or no nitrous oxide – such as showcased in an IChemE Water SIG webinar4 – is also an area of focus along with non-biological nutrient removal.

Mitigation strategies demonstrated at full scale include process optimisation to achieve simultaneous nitrification and denitrification through low (<0.2–0.5mg/l dissolved oxygen) operation in aerobic zones,5 incorporation of new real-time control regimes to limit nitrous oxide production and emission, increasing solids retention time (SRT) by step change in MLSS operation to reduce ammonia loading. However, few have been demonstrated in a sustained manner. While improved process stability and compliance can go hand in hand with nitrous oxide mitigation, this may require trade-offs and case studies remain lacking.

Innovative mitigation demonstrated at scale includes nitrogen recovery to reduce nitrogen load from system and avoid nitrous oxide production and emission and the substitution of very high emitting sidestream treatment processes with lower emission nitrous oxide sidestream treatment solutions.

When practitioners are reviewing mitigation case studies, the evidence of sustained mitigation given the known long-term (including seasonal) variation in nitrous oxide production is important as well as issues of of data integrity and associated metadata for site and instruments (for operating conditions and calibration dates and records).

Many full-scale mitigation strategies have been proposed but not demonstrated at scale and/or in a sustained manner. Those which offer promise include advanced control systems with or without machine learning and artificial intelligence, optimisation of process setpoints to increase or reduce dissolved oxygen levels and balancing of loads and liquors to reduce ammonia loading (including for example step-feed arrangements). Carbon dosing has been demonstrated to reduce nitrous oxide emissions.

Emerging mitigation strategies include technology options – with technologies such as membrane aerated biofilm reactors (MABR) remaining subject to research and development in their potential to offer opportunities to reduce or capture nitrous oxide emissions. In many cases, significant nitrous oxide risks exist – for example for sidestream processes treating high-strength liquors or technologies offering process intensification – but little or no nitrous oxide data exists from full-scale installations. Monitoring is critical to understand nitrous oxide emissions.

Mechanistic and data driven, or hybrid models are emerging with potential to reduce emissions and mitigation actions – these remain in development. In other sectors and in some sewage sludge applications, capture and treatment of nitrous oxide emissions is undertaken through thermal or catalytic destruction – from mainstream or sidestream processes. Catalyst interference and energy consumption given the high temperatures required to destroy nitrous oxide are some challenges identified in ongoing work.

Nitrous oxide is also linked to the wider climate ambitions of the water sector because biogas generation through advanced digestion processes results in higher hydrolysis rates and increased ammonia in recycled streams to WRRFs – an interesting synergy which requires robust life cycle carbon assessment and life cycle analysis across wider impact categories to robustly assess.

Collaboration and collective learning are key

Leading utilities globally are taking action. The International Water Association (IWA) Climate Smart Utilities initiative and sub-group on greenhouse gas monitoring and the Water Environment Federation (WEF) Residuals and Biosolids Community (RBC) are examples of active groups open to professionals, while communities of practice focused on action to reduce process emissions for water utilities exist in the Netherlands, Denmark, Sweden, Australia, Singapore and UK.

Given the rapid learning that is required, such collective efforts are critical and chemical engineers have a key role. Countries which have had national measurement programmes – often collaboratively delivered and funded by utilities, regulators, and supply community and with strong academic support – are making the most progress.

IChemE Water SIG supported a 2022 masterclass series on process emissions with IWA which was developed by the authors and focused on dissemination of the 2022 book Quantification and Modelling of Fugitive Greenhouse Gas Emissions from Urban Water Systems.6 You can find an overview of process emissions and the book in the first masterclass at https://bit.ly/3Z8uKnC. Two subsequent classes focus on the fundamentals of nitrous oxide in WRRFs and taking action to reduce nitrous oxide, while a follow-up series showcased some of the most progressed global work on process emissions in Denmark.

The existing knowledge base provides a solid foundation to measure and reduce emissions of nitrous oxide today, even without the standard approaches to measurement and mitigation and even without a complete understanding of underlying mechanisms of production. The challenge lies in the cost of measurement, good quality of data collection, data interpretation and the risk assessment with implementation of any proposed mitigation strategies.

However, the water sector and WRRFs will not achieve zero emissions with process optimisation and existing abatement solutions alone.

In many countries, we eat more protein than guidelines recommend – for example in New Zealand actual protein intake is 102 g per male and 71 g per female. Recently revised NZ dietary guidelines recommend an average 65 g per day per person. This could reduce nitrous oxide emissions from WRRFs by 25% and lead to a healthier population. A 2023 Finnish study7 concluded that decreasing dietary nitrogen consumption by 16–24% could decrease nitrous oxide emissions by the same percentage and aeration energy consumption by 6–11% in wastewater treatment.

A US study,8 meanwhile, concluded that were US citizens to consume protein at recommended rates, projected nitrogen excretion rates in 2055 would be 27% less than they are today, despite population growth. The study investigated aquatic nutrient pollution and concluded that nitrogen losses to aquatic ecosystems would reduce by 12%. The New York City mayor last year committed to reducing city food-based emissions 33% by 2030 while improving health outcomes through switching to more plant-based menus – we know that the impact will be greater because their WRRF nitrous oxide emissions would be reduced too!

The wider benefits of addressing society’s systemic nitrogen issues with systemic solutions has the potential not just to solve nitrous oxide but related challenges – water quality and nutrient pollution and the wider impacts of our industrial agricultural system which, comprising some 30% of global emissions, must transition from carbon source to carbon sink for a safe future for humanity.

We are breaching six of nine planetary boundaries including those on topic here – climate change and nitrogen – but a good life is possible for all within planetary boundaries if chemical engineers like us, trained to think in systems, step up today to act.

Working in Water

AMANDA LAKE

Having spent the first 17 years of my career being concerned more with nutrient emissions to waterways than the greenhouse gas emissions from WRRFs, the past five years of working on nitrous oxide and actively turning my career to climate work has been an exciting and confronting journey. With this came realisation of the significance of climate and our planetary crises, the importance of water sector process emissions and the fact that no other sector will reduce them except us. Being part of an expanding global network with amazing women like Liu and Aprilia makes working on process emissions fascinating and a real privilege. As chemical engineers we need to consider the risks of climate inaction as critical as risks of process safety and major hazards – and act today.

APRILIA VELLACOTT

I see action on reducing nitrous oxide (and methane) emissions in the water industry as an opportunity to have a society-wide impact on reducing our emissions (in addition to eating less protein) – it can be done now, and doesn’t require a society-wide change to, for example, drive less (although that would be great too). We need to start considering the “invisible” nitrous oxide and methane emissions as detrimental as a spill of raw sewage, and design, operate, and maintain WRRFs to minimise fugitive greenhouse gas emissions. It is inspiring to see the change in the level of engagement, discussion and action in the water industry over the past five years in particular, and it is a privilege to be part of the change.

LIU YE

I work in sustainable wastewater treatment and process control and started looking at process emissions in 2009 when the “carbon tax” was proposed and being debated in Australia. At that time, the focus in the water industry was still on energy efficiency and bio-gas production. There was little knowledge about the emission of the two major direct greenhouse gases – nitrous oxide and methane – from wastewater processes and so I found lots of unknowns to explore. Through past research, we have developed a real-time monitoring system which was crucial to accurately quantifying the process emissions. However, out of >1,000 wastewater treatment plants in Australia, only nine carried out such quantification between 2010 and 2020. In the past five years, I can see more and more water utilities start to take initiative in quantifying and understanding the process emissions through collaboration and engagement with different stakeholders.

References

1. United States Environmental Protection Agency: https://bit.ly/3MuYF1OUN-

2. Water Workshop Report: https://bit.ly/3XqXPth

3. UK Water Industry Research: https://bit.ly/476Wb3n

4. IChemE webinar: Circular Water Series: https://bit.ly/3X6tzTf

5. Mitigating nitrous oxide emissions at a full-scale wastewater treatment plant: https://pubmed.ncbi.nlm.nih.gov/32738601/

6. Quantification and Modelling of Fugitive Greenhouse Gas Emissions from Urban Water Systems: https://doi.org/10.2166/9781789060461

7. Decreasing dietary nitrogen consumption improves wastewater treatment efficiency and carbon footprint: https://bit.ly/3Mv0hZC

8. The impact of excessive protein consumption on human wastewater nitrogen loading of US waters: https://bit.ly/47eEije

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.