Nitrate: An Emerging Solution

Jonathan Wright and colleagues explain how their IChemE Award-winning ion exchange and encapsulated bacteria technologies can combat critical nitrate problems

NITRATE pollution is a major issue around the world, causing serious health effects in humans and severe damage to aquatic environments. Conventional treatment methods often struggle to meet the ever-tightening nitrate limits being mandated around the world.

To overcome this issue, Clean TeQ Water has developed a new process that won the IChemE 2021 Awards Biochemical Engineering category and went on to win the Outstanding Achievement in Chemical Engineering Award. The process, named BIONEX, is a combination of our innovative continuous ionic filtration and encapsulated bacteria technologies, that removes nitrate to very low levels and converts it to nitrogen gas. The process is already being successfully implemented to treat nitrate from wastewater from coal mines and steel facilities in China, as well as in municipal and aquaculture applications.

The impact of nitrate

High concentrations of NOx (nitrate and nitrite forms of nitrogen) in waterways can be caused by fertiliser runoff, and discharge from industrial and municipal treatment plants. Even moderate nitrate concentrations can lead to eutrophication of natural water bodies, causing algal blooms that severely harm the aquatic environment. In 2020 alone, the Harmful Algae Event Database (HAEDAT)1 reported almost 600 harmful algal bloom events globally, and the US EPA’s 2013-2014 National Rivers and Streams Assessment2 rated 43% of rivers and streams as having poor quality in regard to their nitrogen content.

Governments and authorities are now acting to avoid long-term knock-on effects to their clean water resources

Infant methemoglobinemia (blue baby syndrome) has well-established links to high nitrate levels and is one of the main reasons for nitrate concentration limits being set for drinking water around the world. Recent literature reviews of over 30 global epidemiologic studies have found increasing links to various forms of cancer, even when concentrations are below the current drinking water limits3.

For these reasons, governments and water authorities around the world are placing increasingly strict regulations on nitrate concentrations in waters for discharge to the environment, and for drinking. These stricter limits are appearing at the same time as nitrate levels in agricultural and water-stressed areas are increasing, leading the need to urgently upgrade water treatment infrastructure.

For too long, nitrogen issues have been growing unnoticed, and governments and authorities are now acting to avoid long-term knock-on effects to their critical and ever-declining clean water resources. Conventional bacteria treatment methods such as CAS (conventional activated sludge), BNR (biological nutrient removal), MBBR (moving bed bio-reactor), and MBR (membrane bio-reactor) are struggling to reduce effluent nitrate concentrations below the 1 mg/L limit that regulators are requiring. While reverse osmosis and ion exchange can treat to these concentrations, they produce large volumes of waste that can be difficult to manage. Wetlands can be effective for nutrient reduction but have extremely large footprints and are known to struggle to meet the nitrate limits at low temperatures.

We have designed BIONEX specifically to deal with these nitrate issues in an environmentally friendly and cost-effective manner. By combining two of our innovative water treatment technologies, continuous ionic filtration (CIF), and lens encapsulated bacteria (BIOCLENS), the process electively removes nitrate/nitrite from water sources and converts it to harmless nitrogen gas.

How does continuous ionic filtration work?

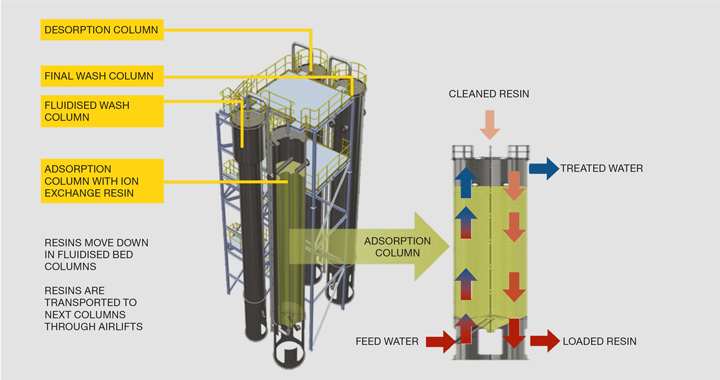

Continuous ionic filtration is a continuous ion exchange technology where ion exchange resin is continuously moved around the system for regeneration. Water treatment occurs in the adsorption column, which uses a moving packed bed of ion exchange resin. It can be likened to the continuous sand filtration process; however, the ion exchange resin continuously removes dissolved ions through ion exchange while simultaneously filtering solids if required.

In BIONEX, continuous ionic filtration is used to exchange nitrate ions for chloride ions on a strong base anionic resin that has strong nitrate selectivity in the presence of competing anions, such as sulfate. The unique counter-current movement of resin in the continuous ionic filtration system results in higher equilibrium loading concentration of nitrate to be achieved on the resin and consistently remove nitrate to <1 ppm. It also ensures there are minimal effects of fouling, which is a limiting factor when using batch ion exchange systems, particularly in wastewaters where bacteria and sludge can be present. Wash water is recovered and reused by the process without the need to discharge it from the system.

Contaminated water flows in through the base of adsorption columns and leaves out of the top through screening elements. Resin loaded with nitrate is periodically lifted pneumatically from the base of the adsorption column into the separate desorption and washing stages, also operated in counter- current fashion, and progressively removes contaminants and desorbs the nitrate from the resin into a nitrate rich salt brine. This leaves washed, nitrate-free regenerated resin to be returned to the adsorption column.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.