Northern Lithium completes two-month extraction demonstration, eying commercial production by 2028

NORTHERN Lithium, a startup planning to mine lithium in the northeast of England, has completed 60-day extraction testing which it says demonstrates “commercial suitability” of its technology.

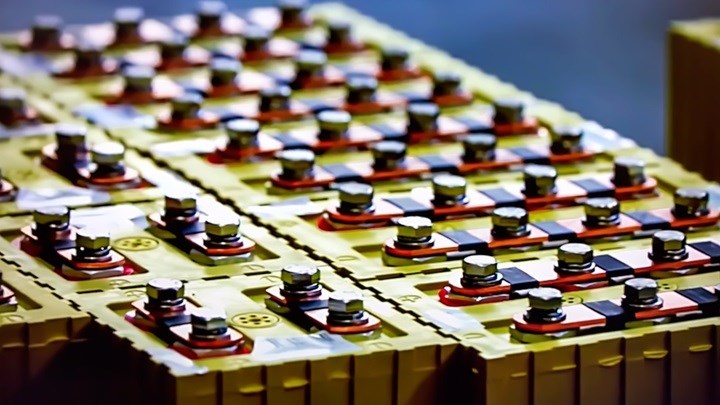

The company said yesterday that over 300 hours of “stable” operation, the demonstration plant achieved 92% end-to-end lithium recovery rates and 96.5% purity of lithium chloride/sulphate. This, the company said, is comfortably high enough for the lithium to be converted into battery-grade lithium carbonate and lithium hydroxide.

Northern Lithium said their tests, which processed more than 3.5m litres of lithium brines at the plant at Ludwell Farm in Eastgate, County Durham, confirmed their first industrial-scale results from 30-day testing in 2024. The company also tested simultaneous abstraction and reinjection of brines at higher flow rates than previously, which they said still proved to be commercially viable.

According to the UK Critical Minerals Intelligence Centre, the UK will need up to 80,000 t/y of lithium carbonate by 2030, to meet surging demand for electric vehicle batteries and energy storage facilities. Northern Lithium aims to produce at least 10,000 t/y of battery-grade lithium products by the end of 2027 from several sites across the Northern Pennine Orefield in County Durham. Following the successful tests, the company is now designing its first commercial plant, which will be 15 times the size of the test plant at Ludwell Farm.

Northern Lithium’s announcement comes after rival company Weardale Lithium secured planning permission in February to build a neighbouring plant on the former Eastgate cement works. Weardale also plans to produce 10,000 t/y of battery-grade lithium carbonate and says they will commission their first plant in 2027.

Nick Pople, Northern Lithium’s managing director, said: “The results of our recent tests and trials have confirmed that Northern Lithium now has the opportunity and potential to scale up supply, within the next decade, to significantly more than our current base case target of 10,000 tonnes of battery-grade lithium delivered per year from a series of production sites across the Northern Pennine Orefield.”

Membrane power

Northern Lithium’s test plant used direct lithium extraction (DLE) that combined membrane filtration ion exchange technologies. The nanofiltration membranes, supplied by specialists Evove, removed divalent ion impurities such as calcium and magnesium from the raw lithium brine. DLE is widely seen as more efficient than more established methods of mining lithium that rely on evaporation ponds, which are slow and water intensive.

Chris Wyres, CEO of Evove, said the company was “delighted that Evove’s advanced filtration technology is helping bring the Northern Lithium project to commercial reality”.

Connor Morton, managing director of water treatment consultancy RSE, who was also involved in design work on the test plant, said the successful testing “marks a major milestone towards the commercial production of lithium…helping to secure a resilient, domestic supply of critical minerals to meet future UK demand”.

The UK currently relies on lithium imports, with global supply dominated by China, Australia, Chile, Argentina and Bolivia. Pople said that owing to the “current geopolitical climate”, the “UK has an urgent need to secure its own domestic lithium supply”. The UK government is set to publish its Industrial and Critical Minerals Strategy later this year.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.