IEA calls for ‘bold’ action to achieve emissions savings through energy efficiency

ENERGY efficiency can help reduce greenhouse gas emissions, but with efficiency improvements slowing, policy makers and investors need to take “bold” action, says the International Energy Agency (IEA).

According to IEA’s World Energy Outlook 2019, energy efficiency – which it views as the “first fuel” of all energy transitions – could save 37% of the difference in energy-related carbon dioxide (CO2) emissions between its Sustainable Development Scenario (SDS) and Stated Policy Scenario (STEPS).

IEA’s STEPS (formerly New Polices Scenario) projects the impact of current policy intentions and targets in addition to existing measures. The SDS outlines the changes that need to be made to achieve climate and other energy goals. Under STEPS, energy-related CO2 emissions are set to reach nearly 36 Gt/y by 2050, but under the sustainable scenario, energy-related CO2 emissions fall to 10 Gt/y by 2050.

According to IEA’s Energy Efficiency 2019, in 2018, primary energy intensity improved by 1.2%, the slowest rate since 2010. Primary energy intensity is an important indicator of how much energy is used by the global economy.

The 1.2% improvement falls well below the average 3% improvement consistent with the IEA’s Efficient World Strategy (EWS), first described in the IEA’s Energy Efficiency 2018. The strategy provides a blueprint showing how energy efficiency could enable energy sector greenhouse gas (GHG) emissions to peak before 2020, achieving energy efficiency targets in the Sustainable Development Goals.

Additionally, due to the 2.3% increase in primary energy demand – the largest increase since 2010 – and the high proportion of fossil fuels in the energy mix, energy sector CO2 emissions in 2018 reached a historic high of more than 33bn t.

The rollout of technologies to rapidly increase efficiency and reduce energy demand must be accelerated to align with its SDS, the IEA says. It adds that more effort is needed across all sub-sectors of industry to put it “on track” with the SDS.

In the iron, steel, and aluminium sectors, scrap metal collection and sorting could be improved to help increase the rate of metals recycling, thereby reducing energy and emissions intensity.

Improvements in the iron and steel sector depend on increasing the amount of steel produced from recycled scrap using electric arc furnaces. This production is 60–70% less energy intensive than primary production. However, scaling up metal recycling requires the availability of cost-effective scrap metal, and globally, this availability continues to be exceeded by the demand for crude steel. The adoption of best available technologies could also improve energy efficiency.

Increasing the recycling rates of plastics, paper, and cardboard would enable less energy-intensive production routes in the chemicals and pulp and paper sectors, helping to get the sectors on track.

Clinker production is the most energy intensive portion of cement manufacture. Adopting more blended cements, using binding materials other than clinker, could enable reduced energy intensity and process emissions.

“Enabling policies are crucial to strengthening energy efficiency,” says the IEA. Cost-effective, commercially-available technologies exist that can improve the energy intensity improvement rate to 3%. Ambitious policies are needed to drive a scaleup in investment to drive their uptake.

Governments are implementing a range of important policies and programmes to improve energy efficiency. For example, the European Union has adopted the Clean Energy for all Europeans package – a set of eight legislative acts – to implement the Energy Union Strategy and meet Europe’s commitments under the Paris Climate Agreement. The aim of the agreement is to keep global temperature rise to well below 2°C above pre-industrial levels and to pursue efforts to limit the increase even further to 1.5°C. The Energy Efficiency Derivative, adopted in December 2018, establishes binding targets of at least 32.5% energy efficiency by 2030, relative to the “business as usual” scenario.

The potential efficiency benefits of digitalisation

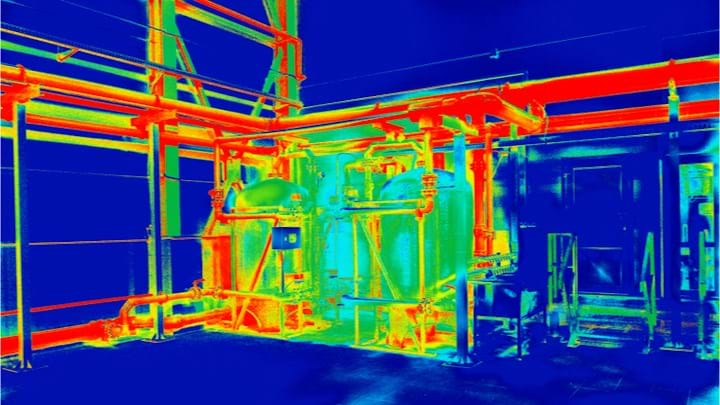

According to Energy Efficiency 2019, digitalisation offers the potential to increase energy efficiency. It can do this by employing technologies that gather and analyse data, then use it to make changes to the physical environment, either automatically or through human intervention.

For example, “digital twins” can be used in industrial facilities and buildings to simulate and optimise how changes to its design affect its energy use. Digital twins are digital replicas of a physical asset within the production process. DigiTwin, a collaborative UK project, is seeking to develop digital twin technology to empower industry.

Digital technology could deliver energy savings across a range of commercial buildings and end-uses, says the IEA. Combining a range of digital technologies and advanced software applications could achieve energy savings for industry of up to 30%. Additionally, digital technology could increase flexible demand capacity ten-fold by 2040, to 450 GW.

“Other benefits of digitalisation include resource efficiency gains, increased health and safety, and reduced operating efficiency.”

According to the IEA, government plays an essential role in ensuring that digitalisation improves efficiency without causing environmental, social, or economic harm. In Energy Efficiency 2019, the IEA identifies a set of policy issues that governments should consider when seeking to increase the use of digital technologies for energy efficiency. Together, the principles form the Readiness for Digital Energy Efficiency framework.

The comprising principles are:

- improve access to energy-related data

- ensure adequate protection from cyber security and data privacy risks

- strengthen trust in digital technologies

- ensure energy markets value the services provided by digital energy efficiency

- ensure suitable access to digital technology and infrastructure

- increase digital skills and plan for job market transformation

- minimise negative environmental impacts

- encourage technology and business model innovation

Fatih Birol, Executive Director of the IEA, said: “The historic slowdown in energy efficiency in 2018 – the lowest rate of improvement since the start of the decade – calls for bold action by policy makers and investors.”

Last year, Spanish energy company Repsol announced it was working with Google to use big data and artificial intelligence to improve efficiency and reduce operational costs at its Tarragona refinery.

In January, IChemE launched an energy and resource efficiency guide which outlines how engineers and organisations can reduce energy and waste to tackle climate change.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.