Trapping a Slippery Foe

Alfonso Rodriguez and Charlie Espinosa explain innovations to map and remove mercury contamination in Colombia

YEARS ago, a 12-year-old Alfonso, in the outskirts of Colombia’s Bogotá, snapped a glass thermometer in his hand when he was about to take his temperature. By then he was already obsessed with chemistry and the heavy, silvery liquid that spilled into his palm captured his imagination. It was not until after he became a chemical engineer and began working for the environmental health NGO Pure Earth that he understood how mercury has poisoned his country.

Today, there are at least 200,000 artisanal gold miners in Colombia. Even though using mercury in mining was banned in 2018, nearly all of them still use it to amalgamate gold from the ore. This practice has turned Colombia into one of the most polluted countries in the world. Over 192 t of mercury are released into the environment annually, littering the second most biodiverse country in the world with heaps of contaminated tailings.

Our approach to this problem has been simple: identify the most contaminated sites and get the mercury out of the environment. But execution is another matter. Like the Roman god from which it takes its name, mercury is elusive and flighty.

Over 192 t of mercury are released into the environment annually, littering the second most biodiverse country in the world with heaps of contaminated tailings

To trap this slippery foe, our team designed a formula to quantify the health risk of a contaminated site and honed a technology that recovers mercury from tailings. But to do this we needed the help of someone who knows the situation best: a miner.

Subsistence Mining in Colombia and the Case of Juan and María

Living in the lush, mountainous region of Northeastern Antioquia, Juan Torres and María come from a culture with a long history of mining. Their great-grandparents were miners, and they plan to pass the tradition on to their children, Camilo and Nicolás.

María is a “Chatarrera” – a term for women miners who sift through piles of gold-bearing rocks discarded by other miners and companies. Juan processes the ore, grinding it into a fine dust and mixing it with water and mercury to amalgamate the gold. Together, they recover about 2 g/d of gold, scraping out a meagre profit that goes directly to supporting their children. Meanwhile, the mercury they use is released as vapour when the amalgam is burned and as effluent into waterways, often in residential areas.

Like many artisanal miners in Colombia, Juan and María are aware of the risks that mercury poses to their health: damage to the nervous system, lungs, kidneys, and digestive system that can lead to miscarriages, respiratory failure, psychotic reactions, and cardiovascular disease. Nevertheless, they depend on mercury for survival because it is the cheapest and quickest way available to recover gold. Mercury-free technologies exist, but miners lack the capital and knowledge to invest in them.

Like many artisanal miners in Colombia, Juan and María are aware of the risks that mercury poses to their health...nevertheless, they depend on mercury for survival because it is the cheapest and quickest way available to recover gold

More artisanal gold miners operate in Antioquia than in any other department in Colombia. The widespread use of mercury has had dire consequences for the region. So far, the Pure Earth team has identified 16 mercury-contaminated sites in the region. While they make up only a fraction of the total, we calculate that these sites alone expose over 30,000 people to mercury.

Ranking the Risk

With so many sites and such widespread mercury contamination, how do we know if Juan’s gold processing plant poses a high-priority risk that should be addressed?

For decades, Pure Earth has wrestled with this type of question. As part of the Toxic Site Identification Program (TSIP), we developed a rapid risk assessment methodology, designed to help governments target interventions. Included in the program was the Blacksmith Index, a formula that ranks the health risk of a contaminated site from 1 to 10.

However, the TSIP program has focused mostly on pollution in soil. This works well for contaminants like lead and pesticides, but not for that shapeshifter mercury, which can evaporate into air and jump into waterways. Something more dynamic and comprehensive was clearly needed. The opportunity arrived last year when planetGOLD Colombia, an initiative of the United Nations Development Program, commissioned Pure Earth to investigate the worst toxic mercury sites in Colombia. As part of the project, our team created a Mercury Blacksmith Index, or BIHg.

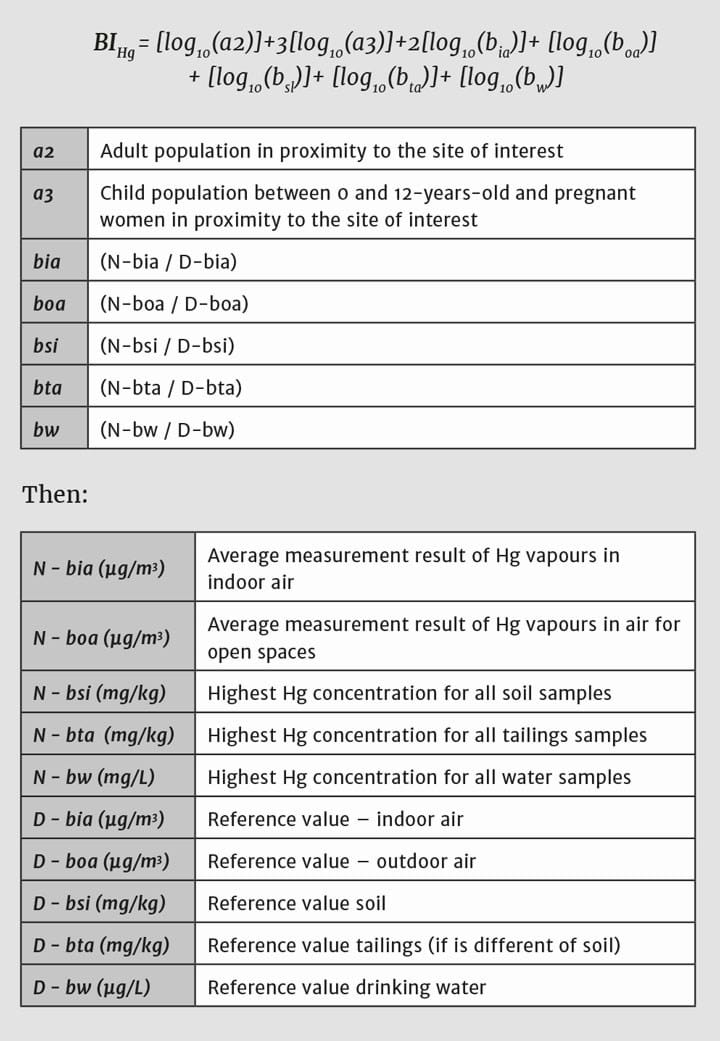

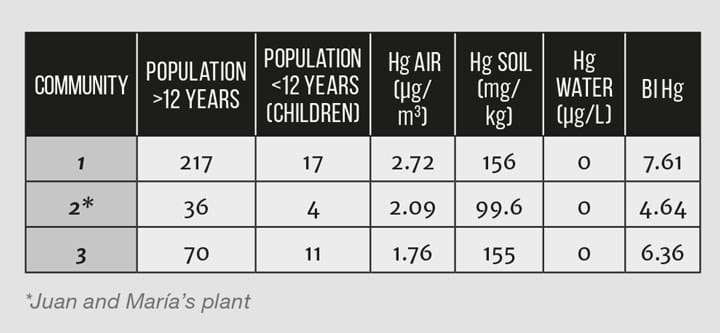

The BIHg analyses soil, air, and water over a target area (maximum 200–300 m in all directions), comparing each measurement to its reference value. It also considers other factors, like population demographics, the number of pregnant women and children under 12 exposed, and whether the mercury amalgam was burned indoors (the formula can be found along with Table 1: Variables of the Mercury Contamination Index).

In early 2020, our team visited Juan and María’s processing plant. Steep hills and mist-filled trees surrounded us, but the plant itself was a barren valley of mining pits and tailings pools. Using a Hermes Mercury Reader and X-ray fluorescence analyser, we took measurements of soil, water and air and inventoried the surrounding population.

We found contamination in Juan and María’s plant, but the BIHg value of 4.64 was lower than two other nearby communities we investigated in the area (see Table 2). This is not to say that Juan and María’s family are out of risk. Only that for the moment, the other two communities should take priority for further investigation and cleanup.

Decontaminating Tailings using a Novel Technology

However, Juan’s plant was rare in a different way: he was one of few miners in Colombia who were reprocessing tailings. Mercury amalgamation typically only recovers less than half of the gold, leaving the remaining gold (and mercury) in the tailings. Capitalising on this deficit, Juan was performing cyanidation on the gold-rich tailings, giving himself an advantage over other artisanal miners.

Juan’s game is a dangerous one. Using cyanidation on tailings that contain mercury can yield even more dangerous mercury-cyanide complexes. When disposed of improperly, this process releases mercury-cyanide complexes into waterways, which are highly bioavailable and pose a big threat to downstream aquatic life.

Even so, we realised that Juan’s situation created an opportunity. If we could remove mercury from the tailings before cyanidation, tailings reprocessing could become an economically viable means of cleaning up mercury contamination in Colombia.

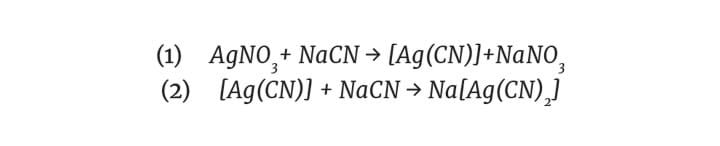

It was Marcello Veiga, a Brazilian researcher in mining engineering at the University of British Columbia, Canada and Technical Advisor with Pure Earth, who first suggested a solution: a Brazilian company named Rio-Sul had recently developed a technique that uses silver-coated copper plates to decontaminate tailings. The technique works by taking advantage of silver’s chemical affinity with mercury, as seen in the following reaction:

Rio-Sul manufactured the plates by electrolytically depositing silver over the copper alloy and then inclining them in a sluice box, so that the tailings cascade down the apparatus. As the tailings pass through, the silver captures mercury, forming an amalgam on the surface of the plates.

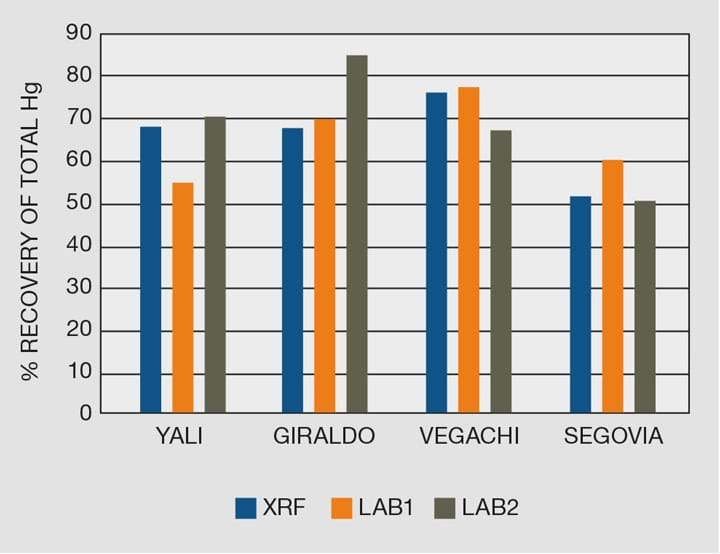

With the support of the US Department of State, we have been working with Juan to test and refine this technology, processing over 80 t of tailings over the past two years in his facility. To improve recovery, we have made some tweaks. Along with electroplating, we impressed grooves into the plates to improve mechanical capture. Additionally, we found the technique works best when the tailings pass over about six 30 cm x 30 cm plates.

We ran into a few challenges along the way. For one, the recovery rate varied considerably according to how old the tailings were and whether they contained other heavy metals or salt oxides. We are also still figuring out ways to capture the organic mercury, which poses a big health risk. Finally, there is the question of how long the plates will last, which has a big effect on how profitable the technique will be. Despite these obstacles, the results have been good. After three rounds of pilot tests, we recovered up to 80% of total mercury from the tailings (see Figure 1).

For Juan, the copper plates are an opportunity to recover gold in a way that is low-risk and actively removes mercury from the environment. He and María are excited to be part of a new form of subsistence mining in Colombia.

Next Steps

Using the mercury contamination index, our team has taken environmental samples across dozens of mercury sites in Colombia and identified the most high-risk areas. Now, it’s time to decontaminate tailings from these areas by working with more miners like Juan.

But the challenges ahead are not merely technical. Ownership of tailings in Colombia is ill-defined, making it difficult to legally commercialise recovered gold. Then, there is the question of finding a facility to store and eventually dispose of the recovered mercury. These are sticky, bureaucratic issues, but we are working closely with Colombian ministries to resolve them.

After centuries of polluting the bodies of rivers and people, it is time we kept mercury out of the hands of future generations

Even as a child on that day when the thermometer broke in Alfonso’s hand, he had the sense that mercury should not be released into the open. After centuries of polluting the bodies of rivers and people, it is time we kept mercury out of the hands of future generations. When combined with other important initiatives, the mercury contamination index and the copper plates can go a long way towards forging a mercury-free future for Colombia.

Pure Earth’s Global Mercury Program works to identify and clean up sites contaminated by mercury, and reduce mercury use in artisanal and small-scale gold mining worldwide. To date, Pure Earth has trained over 1,500 miners to go mercury free, educated nearly 6,000 community members about the dangers of mercury poisoning, and reforested over 8 ha of rainforest polluted and stripped by gold mining in the Amazon.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.