Engineering Net Zero Part 6: Skilling Up

David Simmonds looks at who we need to deliver our energy transition, from the local technician to the grid designer

IN RESPONSE to an article in The Times commenting on the UK Labour party’s stance on oil and gas licences, one pundit called for “clarity and honesty” over the “hundreds of thousands of jobs in renewables [that] are being spoken about”, claiming “no one ever confirms where these jobs will come from and when”. The UK Committee for Climate Change (CCC) has attempted to answer this with their net zero workforce report, which concludes that anywhere between 135,000 and 725,000 net new jobs could be created by 2030 through building retrofits, renewable energy generation, and the manufacture of electric vehicles.

In another report on skills, CCC’s main conclusion is that “no policy aimed at realising net zero can succeed without having people in place with the right skills to deliver on it”. Worldwide, McKinsey estimates that the transition could eliminate six million jobs through 2050, though it could also create 11 million, for a net gain of five million, while Bain & Co recently concluded that “talent shortages are a significant barrier [for our transition], especially for frontline workers in North America and the Middle East and for engineers and digital experts in all sectors”.

As we have already discovered, delivering on skills is very much chicken and egg; without a market it is difficult to train, without a trained workforce it is not possible to grow the market. Many compare development of net zero technologies with the roll out of mobile phones or televisions. However, the latter are standalone pieces of kit, while solar panels, heat pumps, car chargers, and insulation systems need to be integrated into existing networks, systems, and homes, and the complexity of that integration debases exponentially declining costs. Yes, scale and supply experience will reduce costs, but while renewable energy is seemingly free, integrating and harnessing it is expensive. As we know, integration skills are a key facet of engineering, embedded at all levels, from technician to system designer, from networks to home installations.

Looking back at how our energy systems have been built

Before we look to the future it may be worth looking at how we have reached where we are today with our energy networks, our power, and gas grids.

Our gas grid came first, indeed its origins date from the early 1800s, with the first “mains” built in 1831. The Gas Light and Coke Company was actually founded through a Royal Charter signed by King George III. By the 1850s, many competing companies were established and Judith Flanders in Victorian City notes that there were up to ten sets of pipes in just one street in Camberwell. It took another century before 1,048 private and municipal town gas companies were nationalised and placed under one entity in 1948. This entity oversaw the transition from town gas, a mix of hydrogen and carbon monoxide, to North Sea gas during the late 1960s. This stimulated development of a cadre of gas technicians and engineers, trained to meet high standards of safety, and brought real change to our standard of living through the roll out of central heating. The 1986 Gas Act then saw the re-privatisation of the sector under a regulated framework, with standards overseen by the Health and Safety Executive, and installers operating under the CORGI registration system. Since then we have only seen limited expansion and development of the grid, and today’s service technicians are privately trained to meet Gas Safe registration standards (replacing CORGI in 2009), while gas appliances are certified as part of the Gas Appliance (Enforcement) Regulations.

The power grid followed a similar evolution. It was not until the 1880s that the first local power grids were established, designed to replace gas lighting. The Electricity (Supply) Act of 1926 led to the setting up our national grid under the auspices of the Central Electricity Board (CEB). The high voltage grid (132 kV) first operated nationally in 1938, and the Board oversaw training of all staff involved in the sector, and wider electrification of our homes. In the 1970s, the CEB, operating with its European counterparts, established a 400 kV international standard. In 1990, 12 regional electricity companies were sold off as part of the reprivatisation programme. Today these companies also work under the auspices of the Health and Safety Executive, and our electrical contractors, working in people’s homes and businesses, operate under Building Standards codes. They self-certify under schemes overseen by the National Inspection Council for Electrical Installation Contracting (NICEIC) and others.

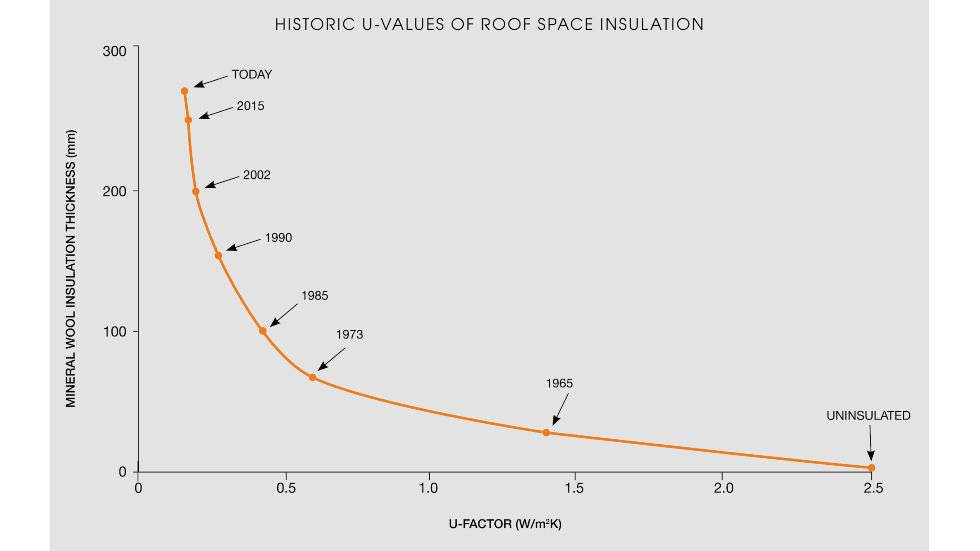

We have long enjoyed the benefits of cheap energy and so the UK has seen limited investment in the insulation of our buildings. Building regulations for heat conservation have evolved over the years, commencing in 1965 when they called for loft insulation of just 25 mm. The energy price shocks of the early 1970s led to a revision of the standard, increasing the required loft insulation thickness to 70 mm, though single skin semi-exposed walls were still allowed. Subsequent changes in 1985 and every five years or so up to 2003 have brought us to today’s standards, requiring loft insulation of 270 mm – see chart which plots mineral wool recommended thickness over time as a function of U factor or rate of heat loss. However, much of our housing stock predates 1965, and many houses built since have yet to be updated to current standards. For example, my own house, built in the 1970s, has a single skin wall between the kitchen and garage, and I recently installed some insulation on the garage side of that wall.

New technology has called for additional services and one body which has evolved over the last 20 years is the Microgeneration Certification Scheme (MCS). Launched as part of the government’s Low Carbon Building Programme in 2006, it has grown into the UK’s certification and standards authority for heat pump/solar PV installers and products. Recently its scope was extended to cover battery energy storage schemes. Future domestic hydrogen appliances would be regulated under an extension of the Gas Appliance (Enforcement) Regulations.

The energy sector has seen change and like many other sectors has developed into today’s self-regulation remit. The availability of contractors is a function of supply and demand, which in a steady state can work well. However, as we look to the expansion of the power grid and electrical services and a possible decline or transition of the gas grid, new pressures will be placed on regulators and contractors alike.

Personal experience with installation of microgeneration systems

In my feature on heating, I recalled some data from our new solar PV system installed in 2021. While the installation of our solar panel/battery system, by an MCS-approved installer, generally went well, it took a year to receive our installation safety certificate and three iterations to receive a correct electrical diagram of our system from our installer. Most household installations need to be customised, and we decided to separate some of our circuits onto the battery loop so that we could retain lighting, boiler, and internet during a power cut. We also had panels installed on both the roof and a side wall.

Since installation we have been very pleased with the system. The annual output is only about 70% of the contractor’s estimated generation because of shading from our garden and neighbouring trees. I anticipated this and so am not disappointed, but others may be very unhappy with this shortfall against quoted specification. Further, there have been a few software glitches and, even with supplier support, I would say that it helps being an engineer to sort them out.

My son-in-law has been keen to install a new solar panel system, and he has had two installers come to prepare quotations. Possibly due to some complexities with his installation, both companies failed to produce an estimate and he has given up his quest.

Installing new technologies does not come without issues for the general consumer who will be looking for independent advice and support. Often installations need to be customised and the industry is not resourced to provide the necessary services. While the UK can secure the innovation capacity to develop new technologies, we currently lack the capacity to widely deploy and integrate new technology, and I believe this to be one of the main gaps in the UK government’s planning for net zero.

Skilling our workforce for net zero

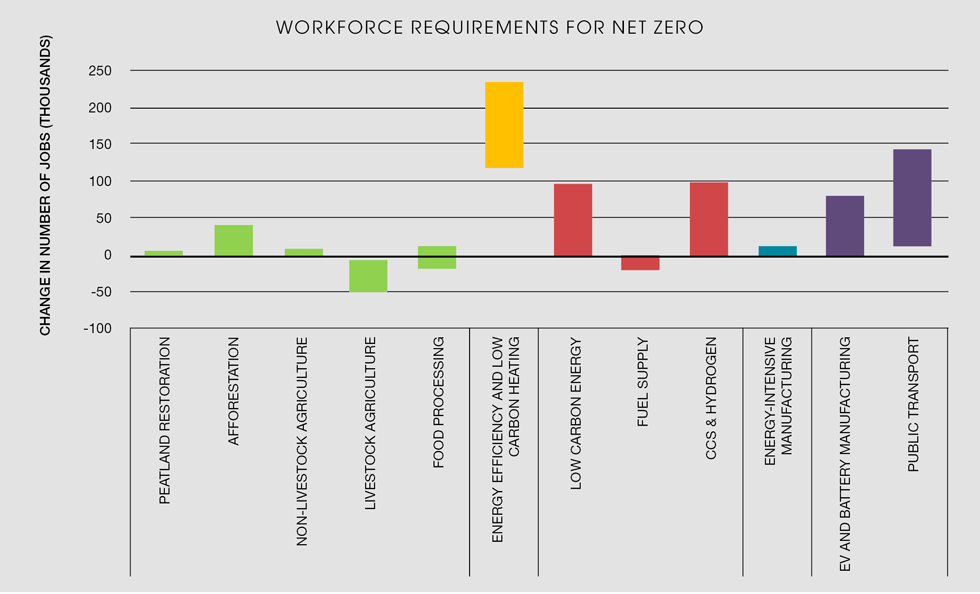

In their Net Zero Workforce report, the CCC has developed the following chart providing some insight into potential job requirements. Unsurprisingly, the main opportunities are in energy efficiency and low carbon heating, energy supply, and surface transport.

Energy efficiency and low carbon heating

As I discussed in a prior feature, CCC and the UK government are looking towards widespread adoption of heat pumps to replace gas boilers in homes and buildings, and they are forecasting anywhere between 100,000 to 250,000 new jobs for the installation programme. As I previously reported, the biggest roadblock to securing take-up is the so-called “Spark-Gap”, the difference in cost of a kwh energy unit of power to gas. Today this is at a factor of four, so while heat pumps offer high efficiency, this price differential does not incentivise adoption. The UK’s differential is higher than elsewhere in Europe and so, in spite of increasing cash incentives, recently increased to £7,500, to offset high upfront costs, it is the major reason for the UK’s pitiful take-up of heat pumps. The government’s answer is to impose a tax on suppliers of new boilers, a move which many see as an unfair levy on those who need to replace their boilers. The government perspective on heat pumps is covered in a detailed Parliament Post briefing.

Even if a customer desires a heat pump, the decision is complicated by the need to design the most appropriate system, deciding between an air or ground source pump (with cost and efficiency differentials), possible hybrid options, and installation requirements often requiring replacement of existing radiators. The effectiveness of a heat pump over a gas boiler is also influenced by the property’s insulation and the customer’s usage profile, especially when a house is regularly unoccupied for periods of time (eg, if the customer is away at work). In a very recent article in The Times, a commentor adopting a heat pump stated: “I soon realised this isn’t just a one-size-fits-all plumbing gig, but there is a real science to it. Every home is unique and requires at least a one-hour survey.” He went on to have all his external walls insulated, plasterboard clad, and underfloor heating pipes installed. Even after the new government grant, he paid twice the price of a replacement gas boiler.

Workforce constraints

The age profile of today’s heating contractors is skewed and retraining programmes for installers are not attracting sufficient interest. Last year, innovation charity Nesta (formerly National Endowment for Science, Technology and the Arts) estimated that there were about 3,000 trained heat pump installations contractors in the UK (MCS have 1,500 certified heat pump installation entities on their books at the end of H1 2023, and state actual installations are currently at a rate of 3,000 per month), and that we need to increase this to over 30,000 installers by 2030 (over 20% growth year on year). It is therefore essential that government entices fresh talent to join the profession. This requires a more significant training initiative and it is encouraging to see that the UK government has just introduced a low carbon heating apprenticeship course. However, other recent efforts to promote apprenticeship schemes have yet to bear fruit, and the sector is challenged by being dominated by small contractors, who will have limited resources to take on apprentices. In their report, Nesta notes that training is fragmented, sometimes inconsistent, and needs practical hands-on experience. Frankly it will remain chicken and egg until the low carbon heating market really takes off. To break this vicious circle, energy trade body, the Energy and Utilities Alliance (EUA), recommends that instead of taxing boiler manufacturers for not selling heat pumps they should be encouraged to pay for the training of heat pump installers. However, it should not pass us by that over 90% of gas boilers are built in the UK, while only 30% of heat pumps are manufactured here.

Further, government policy and customer resistance will put pressure on the UK’s 130,000 gas installation contractors to extend the life of current boiler systems. An early decision on the future of our gas grid is essential, as it could, or indeed in my view should, lead to the adoption of UK-invented hydrogen-ready gas boilers. Acknowledgement of the viability of hydrogen hybrid heat pumps would also increase confidence for heating contractors to pursue competencies with both heat pumps and hydrogen boilers. The retrained workforce will need an intimate knowledge of the technologies and risks.

Looking wider at the challenges, I see a role for a body of “heat architects” to help householders to better insulate and design a heating system optimal for their property and their “warmth” profile. Today, MSC suppliers are experts in their own branded products and are keen to achieve a “sell” without necessarily looking at the consumer’s overall needs. Heat architects should be skilled in improving building insulation, advising on reducing energy usage, and providing guidance to installers. One example of such a service comes from The Heating Hub which already works with heat architects: such architects could also contribute to making our current homes more comfortable and interesting places to live in, something recently featured in the BBC Radio 4 series Building Soul.

As we move forward, many are saying there is also a role for wider use of local power and heating grids which can reduce the need for standalone systems. These too will need appropriate engineering design and installation skills to ensure local services are maintained during the installation. Such schemes will also need staff to develop and implement new billing systems and should extend the services offered by heat architects.

Energy supply

CCC forecasts a requirement for up to 200,000 new jobs in energy supply, split approximately 50-50 between low carbon (renewables/biomass) and hydrogen/CCS. Low carbon energy supplies are labour intensive when one considers both installation of the generation capacity (PV, on- and offshore wind) and associated grid upgrades/expansions. Thinktanks such as the Smith Institute are looking towards extensive deployment of floating wind to meet the UK’s energy demand, which if implemented would require significant human and physical resources.

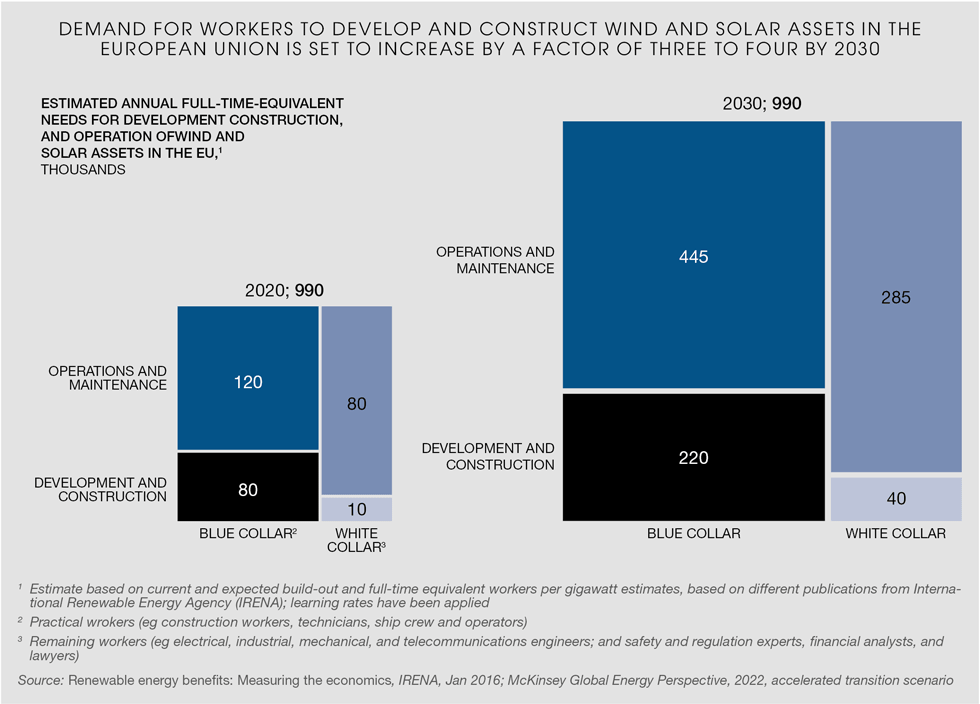

As we have seen, the power grid will have to be expanded by a factor of at least two to ensure adequate power supplies for heat pumps and electric vehicles, including power supplies to remote charging stations. Furthermore, the capacity of the power grid will also have to take account of the intermittency of renewables (viz approximately 15% for PV, 30% for onshore wind and 45% for offshore wind). The government has already earmarked £54 billion for grid upgrades to accommodate recent windfarm approvals and this, with further investment, will result in many new construction jobs. McKinsey estimates that the demand for workers in the EU will increase by a factor of at least three over this decade.

I expect most hydrogen/CCS projects will be undertaken by existing oil and gas/power generation companies, as “Big Oil” has both the capacity and financial muscle to implement much of the government’s hydrogen plans. Most new jobs relating to hydrogen will be through use of hydrogen in industry or domestic.

As we have seen in my earlier feature on heating, there is still a decision to be made over the possible reuse of our gas grid to bring hydrogen to consumers’ homes to supplement heating needs. Safety assessments are in hand along with the development of a suite of standards. Planning and subsequent implementation of a conversion will require considerable resources. It would have to be phased by region and could only commence later in the 2030s. Many of those already operating in the gas sector could be retrained but, as we have seen, we have a skewed age-range workforce, so once a decision on hydrogen to supplement/support the role of heat pumps is made it is essential that plans for retraining the workforce commence.

For me though, the most significant energy supply skills shortage is at a specialist level; in grid design and operation. Here, engineers and economists are needed to model energy system operability and deliverability under a range of intermittency and seasonality scenarios. As noted in earlier features, our power system will see significant changes in demand as we add heating and transport loads, while with renewables the supply system will vary day to night, season to season. Furthermore, current levels of redundancy offered by our gas grid would reduce significantly once it was converted for hydrogen service. Development and capacity of both grids will be influenced by storage options, availability of imports, smart controls, and the relative pricing of the energy vectors.

Personally, I led the modelling of the Dutch gas grid in the mid-1990s as they developed new gas storage and upgraded Groningen production to meet peak winter energy demand. The modelling of our future energy systems to minimise energy blackouts will be an order of magnitude more complex. National Grid has been appointed Electricity System Operator (ESO) by government, and they have published a ten-year look ahead which they continue to refine. National Gas are the lead on the future use of the gas grid, and have recently embarked on a hydrogen backbone study linking our Industrial Clusters. Bringing these systems together into a UK-wide energy plan for net zero will require the significant systems integration skills; skills held by our chemical engineering community.

Transport

CCC foresees up to 200,000 new jobs in the manufacture of electric vehicles and in public services. In an earlier feature I advocated for better public transport to reduce demand for personal transport, so I hope that government policy will lead to increased capacity and better services. Decarbonisation of our buses and trains is already leading to new jobs with companies including Wrightbus in Northern Ireland and Hitachi’s Newton Aycliffe train manufacturing facility, though the latter needs consistency on orders.

Many have criticised the cancellation of the HS2 extension to Manchester, but we will have to see whether this will reduce the number of public transport jobs, as alternative plans for the expansion of bus services and Network North should bring forward orders for more efficient infrastructure.

Development of our EV manufacturing sector is also a function of government policy, and recently we have seen investment support for Jaguar Land Rover, but as highlighted in my previous feature on resources, converting our vehicle manufacturing sector to produce EVs is not without challenge. The supply chains for battery manufacture are tenuous, and today highly dependent upon Chinese lithium supplies, so while we have the workforce potential, the economic model for domestic production is yet to be realised; indeed, we can foresee an avalanche of Chinese cars and batteries.

One area which will demand a new workforce is for the deployment of a fast charger network and hydrogen refuelling stations, the latter primarily for heavy transport. These both require development of new skills and expansion of our apprenticeship schemes. As we are seeing, the former is critical as the government pursues policy targets for electric vehicles, while there is a little more time for the latter as decarbonisation of heavy transport will only really commence in the 2030s.

Will a lack of skills delay us getting to net zero?

The short answer is yes! I deliberately used the CCC workforce report to help premise this discussion as the committee has identified many real jobs but, as we have seen, each area of opportunity is dependent not only upon government policy, but also on government planning. I go back to my initial feature on communication, for without a plan the government is having difficulty getting consumers to commit to new technology, businesses to invest or scale up and, most relevant for this discussion, individuals to commit to (re-)training.

Going forward, there are major uncertainties with respect to the viability of 100% electrification or use of hydrogen in transport and heating. In my earlier features I have suggested that we need to look at how we can deliver synergies between electrons and atoms, but government needs to manage the Spark Gap and I will discuss this further in my final feature looking at energy security and pricing. Once we have a clearer vision for the way forward, businesses and individuals will respond. Many of the jobs CCC have identified need to be filled by people retraining, so that they can deliver with those skills quickly. Unlike a political agenda which stretches at most one or two parliaments, retraining is for life. Government will need to provide retraining support and the confidence that the jobs will be there once the training is complete.

I don’t want to politicise this discussion, but a totally free-market approach is unlikely to succeed. Even the US, home of the free market, is providing a structured and regulated framework through its Inflation Reduction Act, which links project subsidies to the engagement of apprentices in the delivery teams. Furthermore, I have dwelt on the history of our networks, created under the auspices of nationalised entities; these provided scale to support widespread training of engineers and technicians in both gas and power sectors, galvanising real change for consumers during the 1960s and 1970s. There were certainly downsides from the nationalised industries, but we must see how we can learn from their success in delivering training at scale. Indeed, today’s fragmented contracting market for microgeneration services adds to the complexity of getting training programmes and apprenticeship schemes off the ground.

As I have discussed in earlier features, we need to offer consumers more choice in home heating and transport, and we must also offer more impartial advice on how they can reduce their energy bills. While in the longer term we may benefit from larger companies delivering services, we must ensure impartiality, and perhaps an organisation such as Nesta (or IChemE?) can be used to stimulate a fresh talent pool of heat architects to support consumers. Technicians, engineers, and heat architects all need to be appropriately skilled to take on the public-facing nature of their roles so they can bring the wider community along throughout the transition.

As we have seen, we need the younger generation to participate, and in recent polling undertaken by Stonehaven, engineering is in need of some rebranding to attract young people. The decline of apprenticeship schemes and the fragmentation of the delivery sector do not help. Part of the role of IChemE and other institutions must be to encourage young people to enter the profession at both engineer and technician level, linking opportunities to the benefits they deliver to local communities and in achieving net zero goals. TCE has highlighted the need for this in its reporting on the Green Jobs report in 2021 and, more recently, the Cogent study on the green skills gap.

Change is needed at all levels of organisations, and in another report McKinsey recently highlighted how CEOs need to take on a real leadership role for a net zero agenda.

In my last feature I stressed the challenges of growing lithium production 20% year-on-year. Delivering skills to create jobs at similar rates is an equal challenge. However, to answer the pundit at the top of this article, there are jobs to be had from net zero, but they will not be fully realised until the government has the plan to deliver net zero. Along with physical resource constraints, a shortage of skilled technicians and engineers will make it much more difficult to achieve our net zero goal. Worse still, others such as Chinese carmakers may step in and steal the opportunity.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.