Careers in Chemical Engineering: Chris Woodroofe

Yasmin Ali interviews IChemE Fellow Chris Woodroofe about his route to becoming Chief Operating Officer at London's Gatwick Airport

My name is Yasmin Ali and I’m a chemical engineer working in the energy sector. I was originally attracted to study chemical engineering because of the breadth of career opportunities it provides. To showcase this diversity, I’ve been talking to a range of chemical engineers to find out what they do, how they got there, and why they do it. For this instalment, I spoke to Chris Woodroofe, IChemE Fellow and Chief Operating Officer of London’s Gatwick Airport.

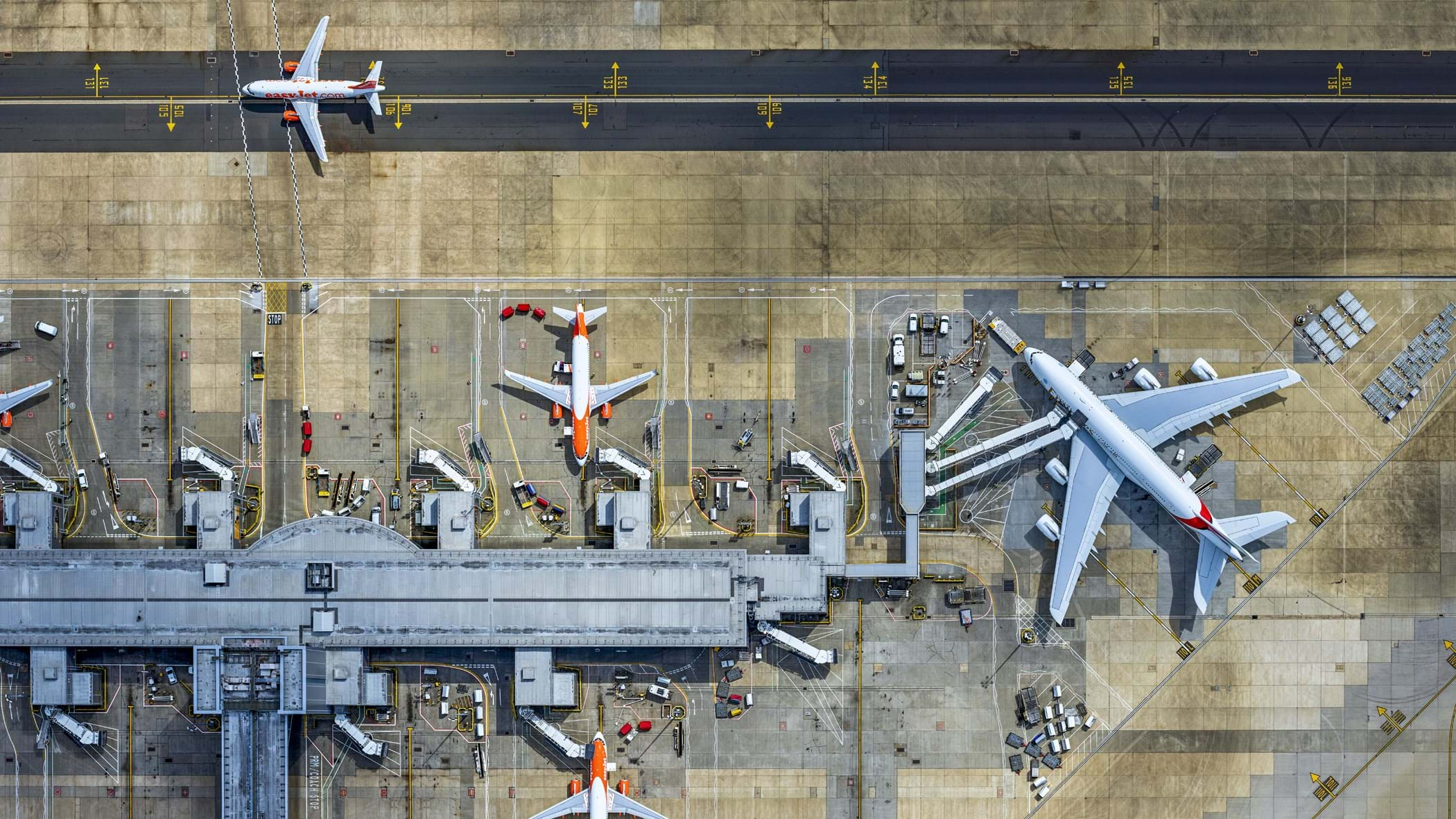

Travelling through airports fascinates me. Passengers are channeled around large terminal buildings, piers and gate rooms completing the necessary processes before boarding their flight, and Gatwick Airport does it well. I find the efficiency of the baggage security system very satisfying, so I was delighted to learn that Chris was Head of Security when it was implemented.

After completing his degree in chemical engineering at Imperial College London, and prior to working at Gatwick Airport, Chris spent six years at Nestlé. He worked in maintenance in Derbyshire, then project management and production in West London. He made the move to the airport when the British Airport Authority, which ran Gatwick Airport at the time, was looking to hire engineers to implement Lean Six Sigma thinking. Chris’s background in manufacturing, a sector well versed with this method, was perfect. He started as an Engineering Manager and worked his way up to Head of Engineering. Following that, he ran security from 2012 to 2015, when Gatwick’s current security screening system for passengers was rolled out.

If you have not experienced it, instead of processing passengers’ bags one at a time through the x-ray machine, the system invites you and six other people to stand on numbered dots on the floor, and simultaneously place your items into the trays, to be fed into the scanner.

Debottlenecking baggage security

“It’s a proper piece of debottlenecking. You see the x-ray machine as the bottleneck, that’s the rate-determining step. In other airports, those machines do 200 to 300 trays an hour, we do 700 to 800 trays an hour through the same machine,” Chris explained.

One operator is only capable of viewing 300 to 400 images an hour on a machine that can display 800; that was the first bottleneck. The designers of the system dealt with it by having additional operators viewing the images remotely, unlocking the full capability of the x-ray machine to process 800 trays per hour. The next step was to find a way of feeding that number of trays in.

“That’s when this idea of the numbered spots comes in. We can’t have people take it in turns to put their things in; we have seven people doing that simultaneously. We tried five, six, seven, eight… and seven was the optimum.”

The final step was to manage the output of the x-ray machine. After a luggage tray passes through, there are two possible outcomes: it’s clear, in which case the passenger can collect it, or it is rejected because it contained something the operators deem dangerous.

“You do the maths, you say there’s going to be x% rejects, that requires three stations per machine to manage rejects. So it’s all done with a proper process engineering head on, and that’s the result you see at the airport,” Chris told me, uncovering the mysteries of a passenger security screening system I have passed through and admired multiple times.

Breaking up the monopoly

This system is held up as world leading, with global airport operators coming to view it. Chris explained how he thinks Gatwick Airport stays ahead of the game – ten years ago, the Competition Commission broke up the British Airport Authority monopoly.

“We were bought by an infrastructure fund called Global Infrastructure Partners, made up half and half of ex-credit Suisse banking professionals and ex-General Electric operational excellent professionals. That’s when the real innovation at Gatwick began.”

The annual capital investment in the airport doubled to over £200m/y, allowing investment in innovative productivity improvement. The aim is to improve the passenger experience and reduce operating costs, while maintaining safety and security.

Accountable for operations

In 2016, after leading a major project to switch airlines between the airport’s two terminals, Chris was offered the role of Chief Operating Officer. He did not hesitate to say yes. He is now accountable for the operation of Gatwick airport – including the airfield, the terminals, security, engineering, and a number of other functions. It’s a team of about 2,600 people, and I asked how he keeps track of everything.

“There’s a monthly rhythm of meetings where we get to look back over finance, HR data, and capital investment programme information about how projects are going… and there’s a process on a weekly basis where things get reported by exception. ” He went onto explain that the majority of issues are dealt with by the responsible teams.

There is also an incident command structure for managing disruption to operations, replicating the emergency services’ bronze, silver and gold structure.

“If about 10% of our passengers or flights get affected, it becomes a silver incident, and then the on-call Head of Department will take control of that incident. If it becomes more serious, and we end up at 50% level of disruption, it becomes a gold incident and myself, the Chief Executive, and the Chief Financial Officer are on call to respond.”

Keeping an eye on the competition

I get the impression that Chris thrives under pressure and in fast paced environments, making this an ideal role for him. He tells me that he goes running a few times a week to clear his head, and plays clarinet in a woodwind ensemble.

“When I’m playing a piece of music in a group with a conductor, my bandwidth is all used up so it’s one of those times when I’m not thinking about work,” he explained.

Some of Chris’s time is spent flying back and forth across the Atlantic, as his wife lives in Philadelphia. Ironically, he has to fly from Heathrow, as there are no flights from Gatwick, but he jokes that it gives him “an opportunity to keep an eye on the competition!”

For more articles in this series, visit https://bit.ly/2DZmjA4

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.