Back to the Future!

Green electricity and electric vehicles: Martin Pitt FIChemE thinks we might have been here before

Solar power –1

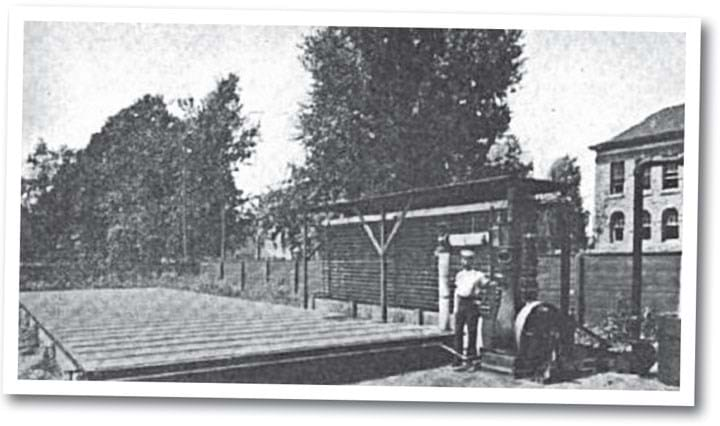

IN EGYPT in 1913 Frank Shuman (1862–1918) constructed a 60 kW solar power unit to drive an electric generator, but for public demonstration purposes, pumped water from the Nile at a rate of 14 t/min to a height of 10 m. Solar power was going to replace most of the coal on which Egypt relied. All that was required was to construct more and larger versions with no new engineering required for fabrication. The technology was proven, economic, and everyone was enthusiastic.

There were no photovoltaic cells: it was thermal solar power, a chemical engineering way of using the Sun’s energy to heat pipes inside parabolic mirrors. It was helped by Shuman’s invention of a low-pressure steam turbine, far more effective than steam engines of the day, and working at lower temperatures.

The German government was so impressed it awarded Shuman a $200,000 contract to build a plant in what is now Namibia, then one of its colonies.

In 1914 came the First World War, and the machinery was scrapped to make items for the conflict. The German contract stopped. Afterwards, Egypt (now a British protectorate) got its energy from British coal or oil from the Anglo-Persian Oil Company. Alternative sources were very much not wanted.

Sadly Shuman died in 1918, and he and the first working solar power station were forgotten, to be re-invented nearly a century later. Had WW1 not happened, or if this dynamic individual had lived, we might have had solar power as routine in sunny countries long ago.

Sunny California also had its solar power inventors. However, the discovery of considerable oil reserves in the state changed matters. By 1914 California produced 38% of US oil, and solar power was forgotten there as well, until the hi-tech buzz of photovoltaic cells in the 1950s.

In thermal solar power, heat boils a liquid such as water to drive either a turbine for electricity or a shaft for a pump or motor. The advantage of thermal systems is that they do not depend on particular elements, but can be made from common materials, and components can be readily recycled. So for very large-scale use, they may be more sustainable. Shuman’s low pressure steam turbine could make smaller cheaper ones feasible.

Solar power – 2

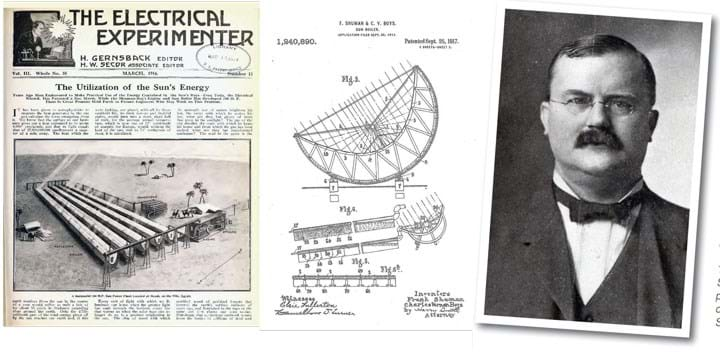

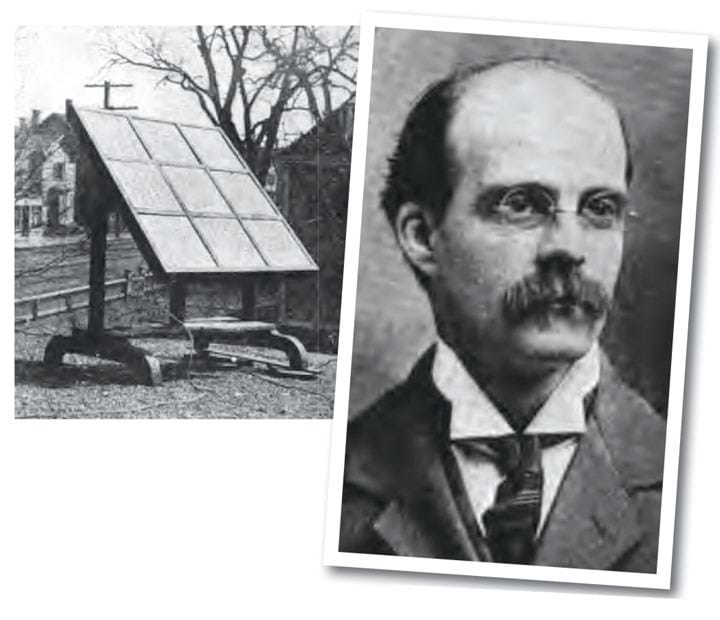

Canadian inventor George Cove (1863–unknown) tried to make solar power using the thermoelectric effect: (as in thermocouples) the difference in temperature between two metal junctions causes a voltage. Effectively a lot of thermocouples (called a pile, like the multiple plates in a battery) can produce useful current.

Via a lot of experiments and talent he produced a system of surprising efficiency. Surprising if you do the sums (which he did), as they show there was far more energy than could be explained in terms of the heat produced. He tried many variations, finding one which was essentially a failure in capturing the heat radiated from a stove, but successful with the sunlight, as he concluded: “When the machine is exposed to various sources of artificial heat it gives no electricity whatsoever. Other than the heat rays of the sun (short-wave infrared), perhaps the violet or ultraviolet rays are active in setting up the electrical current.”

He correctly concluded that it was extracting electronic energy from the Sun’s rays, but had no explanation. It also produced 100s of mV instead of the 10s which come from thermocouples.

Most PV cells today create a boundary sensitive to light (called a p-n junction) between two different semiconductors within high purity silicon by a hi-tech, high energy process (silicon melts at 1,414°C).

By contrast, Cove accidentally created an equivalent boundary (of a different type called a Schottky junction) by putting one semiconductor in contact with a metal by a much simpler and cheaper process. His system consisted of a ZnSb alloy in contact with copper. A different alloy (NiCuZn, known as German silver) made contact at the other end but did constitute a semiconductor.

What happened to George Cove is unknown. He was kidnapped in 1909 and offered money to stop promoting his invention, but refused and was released. His company manufacturing solar panels closed and he was not heard of after 1911. As well as solar power, he was the inventor of a tidal power device, for which he received the gold medal of the Canadian government in 1906, and was planned to be used in the Bay of Fundy but never materialised. Did his kidnappers do more?

In any case it was the 1950s when the first photovoltaic cells were produced to equal the efficiency of his in 1909. His cells did not require the extreme manufacturing and the junction could simply be dismantled to recover the elements, making them more sustainable. This type has been very little studied.

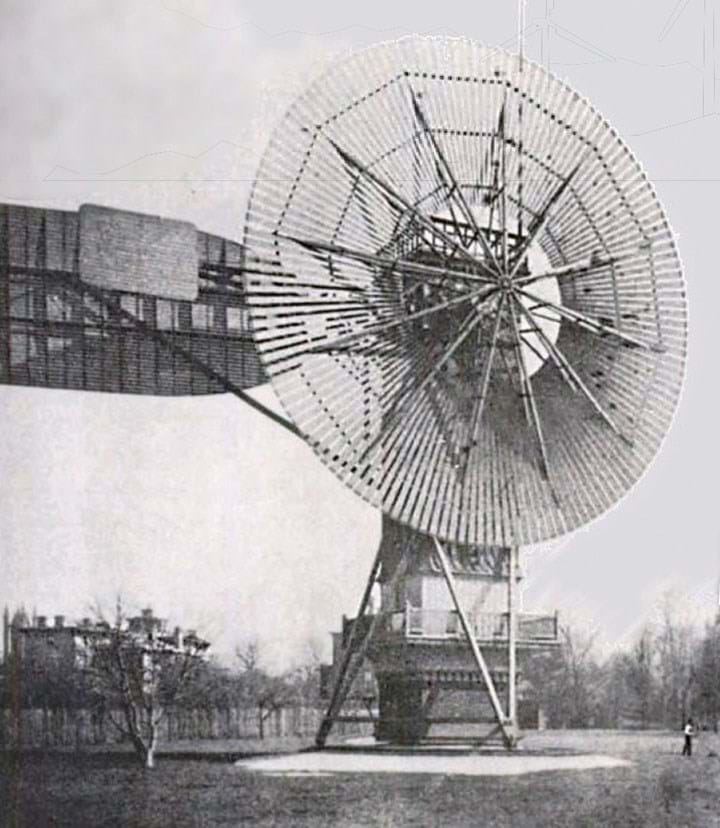

Wind Power

The windmill has been used for more than 1,000 years, for pumping water or grinding materials. The first modern wind turbines for electricity were built at the end of the 19th Century in Scotland, Denmark and the US, the most notable being that in 1888 of US inventor Charles Brush (1849–1929): a 12 kW, 17 m diameter fully automatic unit. He gave up his involvement with electricity in 1891, and the company made no further units.

The compact nature of the UK and plentiful coal meant that wind turbines never made much progress, unlike the larger US with many scattered farms and settlements lacking mains electricity. By 1908 there were 72 electric windmills there, from 5–25 kW, and they were common in the 1930s. However in the 1950s a 100 kW wind turbine operated on Orkney, Scotland.

Modern wind turbines are vastly more sophisticated, powerful and superior to these historic ones, in every way. Except possibly one – sustainability. Which is strange, since that was the point of building them.

The problem is the blades – advanced composite materials and complex shape, designed for function, not recycling. They last about 20 years and have to be replaced (by the latest even more sophisticated materials.) So in many wind farms, old blades just lie around. Others are cut up and buried. Ways of dealing with them are only now being investigated, and mainly as downcycling into low-tech fillers rather than recycling to new blades. End-of-life processing was simply not designed in.

Old wooden windmills were made of local trees and the sails could be rebuilt and replaced many times, the old ones serving at least as firewood instead of chopping down a tree for fuel. Brush’s turbine was made of cedar, twisted like aeroplane propellors, and kept his home fully supplied with electricity for 20 years. However wood is not suitable for much larger aerodynamic blades because it varies in properties through the trunk and around branches etc. It is possible to get round this, and that is what was done on Orkney. The blades were wood, but of laminates, in which multiple layers and different grain directions even out the variations to get a stronger, tougher material. This technique was invented by engineer Bruno Jablonsky (1892–1978), who was rejected by his native Nazi Germany so took British citizenship in 1933 and set up a company which supplied the propellor blades for most British fighter aircraft in WW2.

What are claimed to be the first recyclable wind turbine blades began turning on August 2022. Manufactured in Hull, to a Danish design, by a Spanish company, they are now offshore in Germany at the Kaskasi site owned by RWE for testing. The main ingredients are resin, fibreglass and (yes) wood, designed to be separated with a mild acid solution.

Electric vehicles

Electric cars are not new: they were all the rage in London, Paris, Berlin and New York in the 1900s, accounting for a third of all cars in the US (the rest being steam and internal combustion.) It was an electric car which beat 100 km/h for the land speed record in 1899.

Electric taxis were particularly popular in New York and London; in London, they were known as “hummingbirds” because of the quiet sound they made.

Thomas Parker (1843–1915), described as “the Edison of Europe” was involved in the electrification of the London Underground and many inventions. An engineer who had studied chemistry, he made major improvements to the lead acid battery, giving it more power per volume and making it more robust. It was a key part of the success of his battery vehicles (cars and trams) which he produced from 1884 in Wolverhampton, UK.

Actually, the first electric vehicle was a boat, in 1880. It is perhaps for this reason that many early cars had a tiller for steering. Parker produced cars with steering wheels, or for those who preferred a more traditional feel, with reins. He introduced hydraulic brakes and four-wheel steering.

Ferdinand Porsche (founder of the company which bears his name) produced his first electric car in 1898, and in 1901 a car with a combustion engine driving a generator to power separate motors in each wheel – a hybrid. It was 2010 when the next one was produced by Porsche.

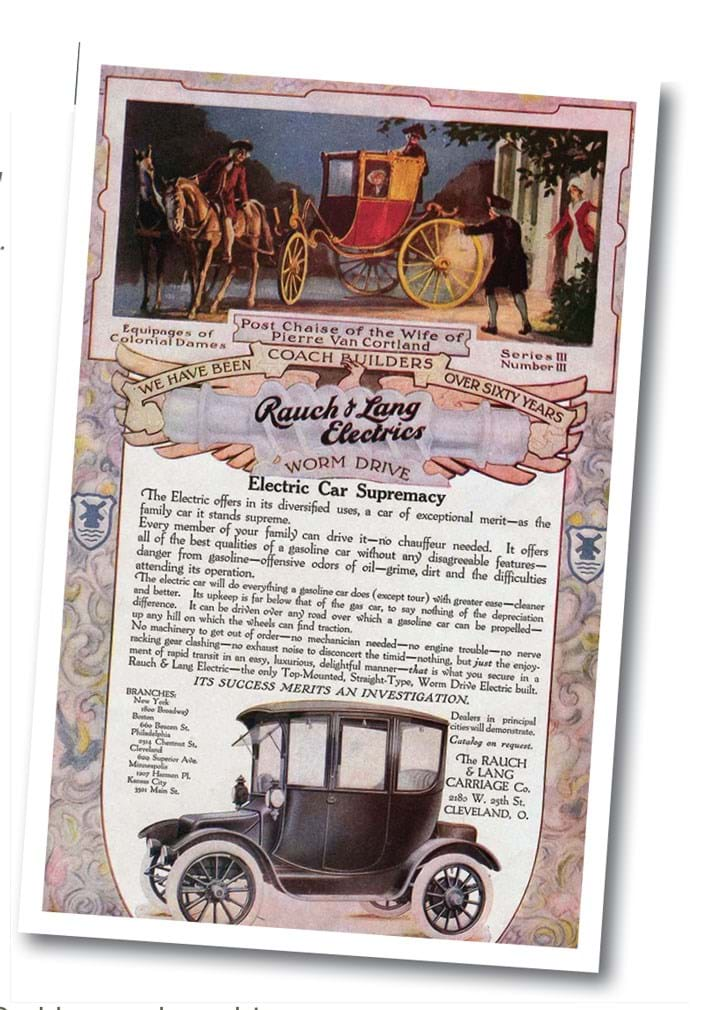

A 1910 advert (pictured, below) touted the advantages of electric over combustion, and admitted the one weakness: “The electric car will do everything a gasoline car does (except tour) with greater ease.” Nevertheless, within cities it was superior. It lacked smell, noise and danger of fire, with no gears needed, and started

immediately without hand cranking. (It was only in 1912 that the electric starter was invented.)

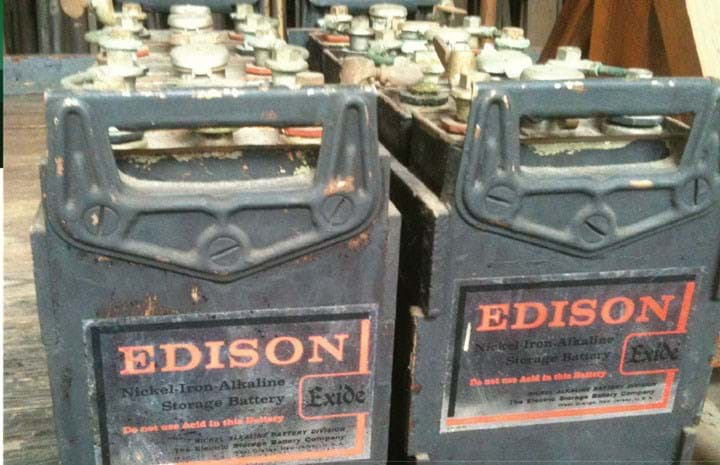

The Lead Trust was a group of investors which controlled lead and lead-acid battery production, and many electric processes and industries, charging fees for use or franchises. Thomas Edison got round this by inventing the nickel-iron battery for his electric vehicles, a robust technology still in use today. However the Trust recognised the potential of the internal combustion engine long before others and bought a patent by Seddon, reckoned to be fundamental for all such vehicles.

In 1902 Henry Ford was offered a licence to manufacture internal combustion vehicles, but instead challenged the patent in court. It was ruled that Seddon only strictly applied to two-stroke engines, not the four-stroke ones of Ford, and the rest is history.

Nikola Tesla may also have contributed to the decline. Any household with a DC electric supply could easily charge batteries. However as Tesla’s more efficient AC system dominated, they would require a mercury arc rectifier – an expensive and rather terrifying glass bulb with lightning and glowing inside. A hundred years later the Tesla corporation is selling electric cars and rechargeable batteries!

For more on IChemE’s Centenary, including historical reflections from IChemE members, visit the dedicated website: www.chemengevolution.org

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.