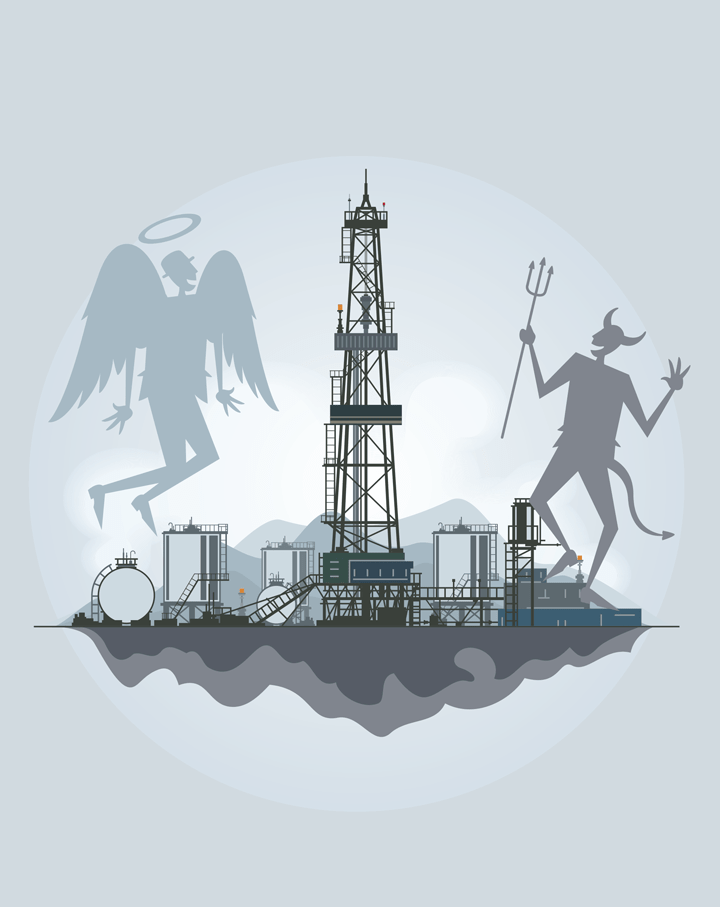

Shale Gas: Friend or Foe?

An overview of the scientific and technical challenges that have surfaced because of shale gas

SHALE gas attracts a lot of attention and creates strong divisions. In North America it triggered an economical renaissance. In countries such as China and Argentina, where enormous shale gas potentials could help achieve energy independence, the industry is pouring in large investments. In Europe, the debate quickly escalated and the landscape is fragmented. France, for example, banned shale gas; Poland would like to produce it but technical problems are in the way; and the UK is experimenting with it and the public is divided. When University College London (UCL) won a Horizon 2020 grant to quantify environmental risks associated with shale gas, one colleague found molasses on his office door, and we were unceremoniously invited to “stop doing public relations for big oil.”

Why is the debate so fierce?

Although modern society seeks alternatives to oil and gas, the path is not clear. The February issue of The Chemical Engineer reported that “France’s parliament has passed a law banning the production of oil and gas in the country’s territories from 2040”; that “Trump proposes opening most US waters to drilling”; and that “Shell will redevelop the Penguins oil and gas field in the North Sea.” Shale gas could provide energy for the years to come, but it is a fossil fuel and as such it is not renewable.

Let us step back, and consider whether shale gas could be an opportunity for a technological renaissance

Producing shale gas has inherent risks, which include, but are not limited to induced seismicity, increased heavy-duty surface traffic, chemicals and hydrocarbons spills, use of large amounts of fresh water, methane migration in the sub-surface, and groundwater contamination. Drilling the wells is complex; hydrocarbons are flammable and explosive. Most oil and gas operations face similar risks, and in some tragic circumstances fatalities have occurred in the sector. Engineers should continue to design preventive, mitigative and remedial procedures to contain such risks. The highest standards of safety must be implemented in any industrial operation, including the production of shale gas. Yet, the risks exist.

But let us step back, and consider whether shale gas could be an opportunity for a technological renaissance. In this article I propose some possible future developments in fundamental and applied research, as well as in education.

Do we need shale gas in the first place?

The International Energy Agency (IEA) estimates that oil and gas demand, worldwide, will continue to rise at least for 20 more years. While we pursue the development of renewable energy sources, one notices that shale formations are ubiquitous. The IEA reported that shale formations are present in 42 countries. The estimated recoverable reserves in China alone (1,115trn ft3) could supply the UK for over 350 years at current demand. The Department for Business, Energy & Industrial Strategy reported that the UK consumed ~3trn ft3 of natural gas in 2016: ~33% of it produced electricity, 35% was used domestically and ~17% industrially. More than half of the natural gas consumed in the UK is imported.

How is shale gas produced?

Two major innovations enabled the shale gas revolution. One involves directional drilling, where the wells extend horizontally from the well pad. The other is hydraulic fracturing, which attracts the public’s ire. Stanolind Oil and Gas Operation pioneered hydraulic fracturing in the 1940s in Kansas, US. Millions of “frac jobs” have now been performed on oil and gas wells. By pumping water, or other fluids, hydraulic fracturing creates a fractures network within an otherwise impermeable formation. Sand and other proppants maintain the fractures open to facilitate gas production.

Many fundamental challenges still exist, many of which align with the traditional chemical engineer’s toolbox. It is estimated that only 15-20% of the gas in place is produced. The rest remains within the shale formation. How could this latter gas be produced? Could, for example, CO2 enhance production, yielding the added benefit of permanent carbon sequestration?

It is difficult to precisely quantify the amount of hydrocarbons present within a formation. New tools are needed to measure gas adsorption at pressure and temperature conditions typical of the geological formation, to visualise the existing pore network within a shale rock, to test the mechanical properties of the rocks, and the crack propagation when the rock is fractured.

Advanced instruments such as synchrotrons or X-ray computer tomographs are required to visualise the 3D pore network in shale rock samples. While all shale rocks are different, their pore networks are not isotropic and lack connectivity.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.