Sabic to assess Coolbrook’s greener cracking technology

SABIC has agreed to assess Coolbrook’s turbomachine technology which is being piloted as a greener alternative to steam cracking. If proved viable, the technology could help Sabic and other chemicals firms decarbonise ethylene production.

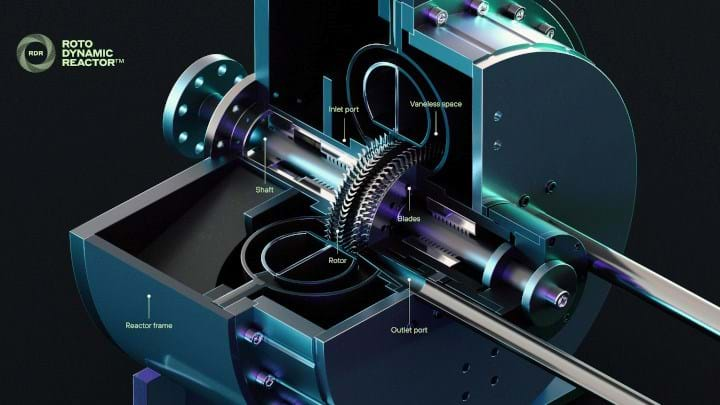

The Saudi chemicals major has agreed to assess Coolbrook’s pilot project, which is undergoing tests at the Brightlands chemicals innovation hub in the Netherlands. Coolbrook says its rotodynamic reactor (RDR) technology can replace a conventional furnace by directly imparting the rotor shaft’s mechanical energy to the hydrocarbon fluid.

The electrically-driven turbomachine, powered by renewable energy, would be used in place of the fossil-fueled steam cracking processes that industry uses to produce olefins such as ethylene and propylene. Coolbrook estimates that its electrification technology could reduce global CO2 emissions by 300m t/y, and says it will improve energy efficiency and increase ethylene yield by up to 20% compared to traditional cracker technologies.

The collaboration grants Sabic access to the results of Coolbrook’s pilot project. Sabic said it will use the results to evaluate the potential of deploying the technology at its own production sites.

Joonas Rauramo, CEO of Coolbrook, said: “Sabic is a global leader in petrochemicals, and we have already established a close cooperation relationship in the Netherlands, where both companies have a strong presence. We are confident that together we can have a significant impact on reducing the climate impact from ethylene production here, and globally.”

Sabic is involved in several partnerships investigating how electrification of cracking can help it reach its target to reduce emissions by 20% by 2030, and become carbon neutral by 2050. It is working with BASF and Linde to develop electrical-powered cracking and expects to commission the first commercial-demonstration scale facility later this year.

Separately, Coolbrook announced earlier this month it would work with Linde to develop and deploy its RDR technology. Last year, it formed a partnership with ABB, which is helping with the automation, electrification, and digitalisation needed to optimise the operation of the technology.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.