IChemE awards engineers who 3D print reactors

ENGINEERS from Air Liquide who are 3D printing reactors for the purpose of process intensification have been awarded IChemE’s Hanson Medal.

Raphaël Faure, Matthieu Flin, Pascal Del-Gallo and Marc Wagner, based at Air Liquide’s office in Paris, were awarded the medal for their article “Add It Up!” which was featured in issue 928 of The Chemical Engineer magazine.

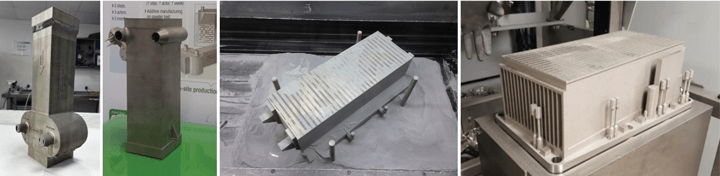

Earlier today, members of the team presented a webinar discussing how they are using additive manufacturing – more commonly known as 3D printing – to create smaller, more efficient reactors for hydrogen production using steam methane reforming (SMR).

“A classical SMR tube is a tube around 10 cm diameter, filled with catalyst. Internal mass transfer is limited,” said Flin.

“We wanted to use all the catalyst we put inside. One solution could be to have a thin layer of catalyst coated on smaller diameter channels.”

The team says its resulting milli-structured reactor takes up less space, uses less natural gas and produces less CO2. The use of 3D printing techniques – in this case laser beam powder bed fusion (LB-PBF) – streamlines prototyping and reduces costly and time-consuming machine tooling steps. It also enables engineers to print equipment with shapes not possible using traditional subtractive engineering techniques such as milling.

Though on balance, the team noted that 3D printing has its limitations. The size of equipment that can be printed is constrained by the size of manufacturing trays. Also, additive manufacturing is not recognised under certain key regulations. Air Liquide, along with others from industry, is helping develop a new chapter of the unfired pressure vessel regulation EN13445 to allow additive manufacturing.

The medal was presented by Nilay Shah, Chair of IChemE’s Publications Medals Panel. Shah said: “3D printers are an incredible tool for chemical engineers to use in industrial and academic applications, and the team’s article describing their use of the technique to look at ways to improve traditional chemical manufacturing processes was hugely interesting and inspirational to chemical and process engineers across the world. I would like to congratulate the team for their work in this area and for bringing this application to the forefront with their article in The Chemical Engineer.”

Reacting to the award, Faure said: “We are very proud to have been awarded the Hanson Medal by IChemE. Manufacturing and chemical engineering are not always so closely associated. With our Air Liquide colleagues, we succeeded in considering new possibilities as offered today by additive manufacturing, bridging the gap between the limitations of traditional manufacturing processes and what we can dream of by process intensification concepts. This project has been really interesting, challenging and satisfying to work on and so we were delighted to be able to share some of our thoughts in this article.”

The Hanson Medal is awarded to the author or authors of the best article to appear in IChemE’s magazine, The Chemical Engineer, each year and is named after a past chair of the Editorial Advisory Board. The Editor of The Chemical Engineer initially nominates suitable candidates for the medal, and the final decision is made by the Publications Medals Panel before being approved by the Medals and Prizes Committee.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.