Separation Anxiety

Darren Broom discusses the need for new developments to address the challenges around multicomponent gas mixture instruments

In 2019, the US National Academies of Sciences, Engineering and Medicine published a report entitled A Research Agenda for Transforming Separation Science.1 The report was compiled and reviewed by leading figures from academia and the various industries that rely on chemical separations. Such separations underpin a large proportion of industrial activity, and the many processes developed over the last century or so have been enormously successful. However, there is a heavy reliance on rather energy-intensive distillation.

Lower-energy alternatives for separating and purifying gases include membrane separation and the use of adsorbents in processes such as pressure swing adsorption (PSA) and temperature swing adsorption (TSA). PSA is often a more logical choice at smaller scales. Indeed, small-scale gas production using PSA has been thrust rather grimly into the public eye during the recent coronavirus crisis, with many oxygen PSA concentrators being shipped to India as conventional hospital supplies ran out.

Nevertheless, adsorption is also used on a larger scale – eg in a pre-purification step in which water, CO2 and other contaminants are removed from air prior to cryogenic distillation to prevent freezing in distillation columns. PSA is also commonly used to recover and purify hydrogen from a variety of hydrogen-rich gas streams, such as steam methane reformer and refinery off-gases, while TSA is used on a large scale for drying and desulfurisation in natural gas processing.

PSA has been thrust rather grimly into the public eye during the recent coronavirus crisis, with many oxygen PSA concentrators being shipped to India as conventional hospital supplies ran out

The National Academies report identified a number of areas of separation science that could be addressed to advance the field and lead to development of new, more efficient separation processes. They were grouped into two general themes: designing separation systems that have high selectivity, capacity, and throughput; and understanding temporal changes that occur in separation systems. Two cross-cutting topics were also identified: establishing standards to enhance reproducibility and adapting data-science methods to accelerate the development of separation systems.

A key part of designing adsorptive separation systems is understanding multicomponent gas adsorption equilibria – the amount of each gas adsorbed by a material from a mixture at a given temperature and pressure. This requires accurate and reproducible multicomponent measurements, a task that is unfortunately not trivial.

A lack of fundamental understanding

An interesting aspect of separation science is the degree to which fundamental understanding lags behind the technology. As Timothy Golden of Air Products wrote recently: “despite failure to totally understand the complexities of multicomponent equilibrium and mass transfer we continue to build separation devices which work”.2 The understanding which could lead to improvements in existing processes and development of new ones is therefore lacking.

In a 2019 commentary Krista Walton of Georgia Institute of Technology highlighted some of the issues, referring to “the persistent nature of the mixture-adsorption knowledge gap”.3 Alongside a decline in academic expertise in the area and funding restrictions, Walton noted the lack of commercial instrumentation available for multicomponent gas adsorption, as well as the difficulty of making such measurements.

“Push-button” instruments for measuring single-component (pure gas) adsorption have been commercially available for years, but this is not the case for multicomponent adsorption. If instruments cannot be bought easily, and must instead be built in-house, the barrier to entry for individual researchers – and companies – new to the area is much higher. Walton concluded that “until access to commercial multi-component adsorption systems is comparable to that of pure-component instruments on the market, the knowledge gap on adsorption of complex mixtures is likely to persist.”

Measurement challenges and data scarcity

The inherent difficulty of multicomponent measurements revolves around the need to determine the different amounts of each component adsorbed by a sample exposed to a gas mixture. Achieving equilibrium is often problematic in the presence of mixtures in which different species may diffuse at notably different rates through the pores of a material, and thorough gas mixing is required. Homogeneous conditions must be reached throughout the adsorption column and measurement system to ensure measurements are made under thermodynamic equilibrium. Most existing methods are therefore time-consuming, often requiring large samples due to the need to increase the sensitivity of a system to changes in the amount of each component adsorbed, which is usually determined indirectly from changes in gas phase composition.

These measurement challenges have led to a paucity of multicomponent studies. It is often noted that not many multicomponent gas adsorption datasets are available in the literature, and this is certainly true for mixtures of three or more components. A database compiled recently by the US National Institute for Standards and Technology (NIST)4 contains over 20,000 experimental adsorption isotherms for various gases on different adsorbents, but these are mostly single component.

However, a recent literature meta-analysis revealed a surprising amount of binary adsorption data.5 The study led to the compilation of the BISON-20 database, which contains 908 sets of binary adsorption data, from 263 references, on various adsorbents. Analysis of datasets measured on similar materials for particular gas mixtures under similar conditions indicated large discrepancies between independent measurements. It is also worth noting that 263 references is a rather small proportion of papers published on gas adsorption. Over 11,000 articles were screened for binary adsorption data during the meta-analysis. The difference between these numbers illustrates the gulf between the study of pure gas and multicomponent adsorption.

Commercial complications

Pure gas adsorption is usually measured using either manometric or gravimetric methods, which involve dosing gas into a chamber or calibrated volume and monitoring either sample weight or pressure over time, until equilibrium has been achieved. More gas is then introduced and the process repeated. All measurements are performed at a fixed, constant temperature. It is perhaps easy to see why push-button instruments for such measurements have been widely available for decades.

For multicomponent measurements, the situation is very different. One of the most accurate approaches to measuring multicomponent gas adsorption is the total desorption method. This involves first equilibrating a gas mixture with an adsorbent bed in a flow-through system. Following equilibration the bed is isolated. The entire contents of the adsorption column are then desorbed into a separate volume by heating the bed and cooling the collection volume, typically using liquid nitrogen. This process is rather lengthy. Following complete desorption, the adsorbent bed is isolated again and the collection volume allowed to warm to ambient temperature. The gas composition in the collection volume is then determined and used to calculate the amount of each gas adsorbed in the bed under the original equilibrium conditions. This provides a single data point, in terms of temperature, total pressure, and gas composition.

It is difficult to envisage a push-button instrument that could perform all these various steps and produce a final dataset without considerable intervention from the user; bearing in mind that all steps in the process must be optimised for each adsorbate-adsorbent system. Measurements must also be very accurate to provide high quality data, and the gas composition analysis may need to be tailored individually to the gas mixture under investigation.

Other, quicker methods are available, most notably open volumetric or dynamic column breakthrough systems, but they tend to be less accurate and require larger sample sizes. Equipment may also need to be tailored to the required measurements, in terms of bed dimensions, concentration ranges and gas flow rates. For open volumetric measurements, the main technical challenge is accurately determining total outlet flow rate, because gas flow is difficult to measure to very high accuracy and the outlet composition is continually changing, except under equilibrium when the measurement is essentially complete.

Despite the details, the key point is that commercial push-button instruments for making multicomponent measurements have yet to emerge, and this is clear from the lack of data in the literature. Most multicomponent measurements are instead performed by chemical engineering groups with considerable expertise, either in universities and research institutes or in companies working on adsorption technology.

For instrument manufacturers, potential market size is a crucial commercial consideration. Despite the importance of multicomponent measurements for developing and improving separations, the market for such instruments is likely to be relatively limited – compared, for example, to measuring nitrogen adsorption at 77K to determine BET (Brunauer-Emmett-Teller) surface area, one of the most common types of pure gas adsorption measurement. Instruments for this purpose can be found in most materials chemistry laboratories and in characterisation facilities in a vast range of fields and industries, including pharmaceutical sciences, geosciences, and catalysis. BET analysers are therefore sold in relatively large quantities by various companies, but this seems unlikely to be the case for rather complex multicomponent gas adsorption instrumentation, which has a far narrower range of applications.

A new technique

The best chance of producing user-friendly instruments for multicomponent adsorption may be to develop new techniques, rather than implementing existing approaches. Hiden Isochema, working in collaboration with Orhan Talu of Cleveland State University, recently introduced a new approach, called the integral mass balance (IMB) method.6 This offers some promise toward the more routine and rapid characterisation of multicomponent adsorption by porous adsorbents as it combines the speed of open volumetric systems with the accuracy of more laborious techniques.

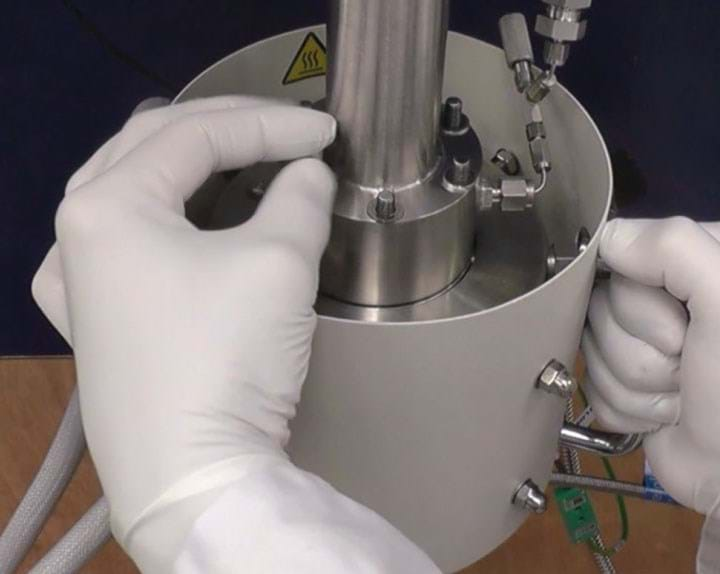

In the IMB method, a gas mixture is flowed through a system in which the weight change of the sample as a function of time, dw/dt, can be measured. The gas composition at the outlet is determined in real time using a quadrupole mass spectrometer and a mass balance expression used to calculate the amount of each component adsorbed, by integrating the differential gas composition and sample weight signals. The IMB method is similar in principle to open system volumetric measurements, but determining sample weight in situ eliminates the need to measure the total outlet flow rate, the main limitation of open volumetric systems with respect to accuracy.

We validated the technique by replicating binary oxygen and nitrogen adsorption isotherms measured on a commercial zeolite 5A sample and published previously in 1996. Good agreement was found, but the crucial point is the speed with which the replication was performed. The original measurements were made in the US on two systems, one at Cleveland State University and the other at Air Products in Allentown. Approximately one day was required to measure each data point in the original study, but a 20-point binary adsorption isotherm was measured in only four hours using the new technique. This perhaps takes us a step closer to push-button multicomponent gas adsorption measurements.

Binary O2/N2 adsorption, as used to validate the IMB method, relates directly to oxygen production from air using PSA. Commercial O2 PSA concentrators currently use zeolites, and such units have important applications not only in medicine, but also in a range of other industries. Oxygen Solutions Inc (OSI), based in Alberta, Canada, for example, produces O2 concentrators for use in aquaculture, wastewater treatment, mining, and the pulp and paper industry as well as in medicine. Many other suppliers exist, however – the largest manufacturer in Europe is Oxymat, based in Helsinge, Denmark. Oxymat also makes N2 PSA generators.

Testing the IMB method for measurements relevant to other separations will require further work. A variety of gas mixtures could be targeted under varying conditions. N2/CO2 adsorption data, relevant to CO2 capture from power plant flue gases, for example, was published recently,7 but other examples include CH4-containing mixtures for various aspects of natural gas processing and hydrocarbon mixtures that are difficult to separate, such as propylene/propane and ethylene/ethane. These light olefin/paraffin separations are essential for the production of high purity ethylene and propylene for use as chemical feedstocks, and current distillation processes consume vast amounts of energy.

The US National Science Foundation (NSF) also recently funded a project in the Department of Chemical and Petroleum Engineering at the University of Kansas (KU), led by Mark Shiflett, to further develop the IMB method. Shiflett, who moved to KU in 2016 after 28 years at DuPont is also leading Project EARTH, another NSF-funded project which aims to develop sustainable separation processes for environmentally harmful hydrofluorocarbon (HFC) refrigerant mixtures, and the IMB method is being used in this work.

Outlook

Despite recent progress, the challenging aspects of multicomponent gas adsorption measurements are likely to remain a difficult problem for the foreseeable future. There is still a considerable step from quickly and accurately measuring binary gas adsorption isotherms to developing a full understanding of the behaviour of adsorbents in complex mixtures. Nevertheless, the developments described here provide a clear path forward. Compilation of databases, such as those at NIST and BISON-20, should allow the current state of knowledge in the field to be assessed, and help identify particular gaps, while introducing new measurement techniques should increase the amount of multicomponent gas adsorption data in the literature.

It is difficult to overstate the importance of gas separations. Providing affordable, reliable and efficient life-saving O2 supplies in the recent pandemic is a prime example. But more broadly, wider adoption of more efficient separation processes such as PSA and TSA could notably reduce energy consumption by industries reliant upon separations, leading to significant reductions in CO2 emissions. Advancing separation science by addressing some of the problems covered in this article could play an important role towards achieving this goal.

References

1. A Research Agenda for Transforming Separation Science, 2019, National Academies of Sciences, Engineering, and Medicine, National Academies Press: Washington, DC, https://doi.org/10.17226/25421

2. Golden, TC, “Dr. Shivaji Sircar: the Air Products years (1973–2001)”, Adsorption, 2021, 27, p535-539.

3. Walton, KS, “110th Anniversary: Commentary: Perspectives on adsorption of complex mixtures”, Ind Eng Chem Res, 2019, 58, p17100-17105.

4. Siderius, DW, Shen, VK, Johnson III, RD, van Zee, RD, NIST/ARPA-E Database of Novel and Emerging Adsorbent Materials, NIST Standard Reference Database Number 205, National Institute of Standards and Technology, Gaithersburg MD, http://adsorbents.nist.gov

5. Cai, X, Gharagheizi, F, Bingel, LW, Shade, D, Walton, KS, Sholl, DS, “A collection of more than 900 gas mixture adsorption experiments in porous materials from literature meta-analysis”, Ind Eng Chem Res, 2021, 60, p639-651.

6. Broom, DP, Talu, O, Benham, MJ, “Integral Mass Balance (IMB) method for measuring multicomponent gas adsorption equilibria in nanoporous materials”, Ind Eng Chem Res, 2020, 59, p20478-20491.

7. Bell, JG, Benham, MJ, Thomas, KM, “Adsorption of carbon dioxide, water vapor, nitrogen, and sulfur dioxide on activated carbon for capture from flue gases: Competitive adsorption and selectivity aspects”, Energy Fuels, 2021, 35, p8102-8116.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.