Practical Process Control Part 4: Tuning a PID Controller

Myke King continues his detailed series on process control, seeking to inspire chemical engineers to exploit untapped opportunities for improvement

If there was an award for the engineering subject that has prompted the largest number of research papers, then tuning the PID controller must be one of the contenders for the top spot. The Handbook of PI and PID Controller Tuning Rules, written by Aidan O’Dwyer, includes most of the techniques published between 1935 and 2008. These number several hundred and many more have been developed since. The advent of computer simulation removed the need to use costly instrumentation and allowed research to fit into limited budgets. It provided the means for many students to gain their Master’s degree or PhD. Further, chemical engineering is not the only subject in which process control is taught. The pool of potential researchers includes engineers from the mechanical, electrical and systems engineering departments.

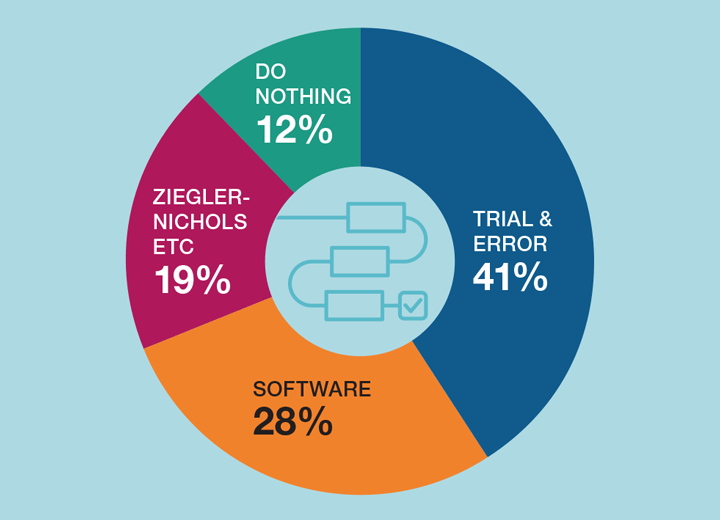

Figure 1 shows the results of a survey carried out in 2019. Given the availability of so many tuning methods, it might be surprising that only 19% of engineers are using them. Tuning by trial and error is still the method of choice for many. This is time-consuming. The time to steady state, following a process disturbance, can be calculated from the process dynamics (as θ + 5τ). For our example fired heater (Issue 981), this would be around 30 minutes. Given the number of trials necessary to optimise tuning, such a controller would take several days to tune. In practice, the engineer is unlikely to spend the time necessary and will stop when the tuning is acceptable – almost certainly leaving scope for improvement. Further, given the shortage of expertise within the process industry, the time spent could have been put to better use in implementing new controllers.

Tuning criteria

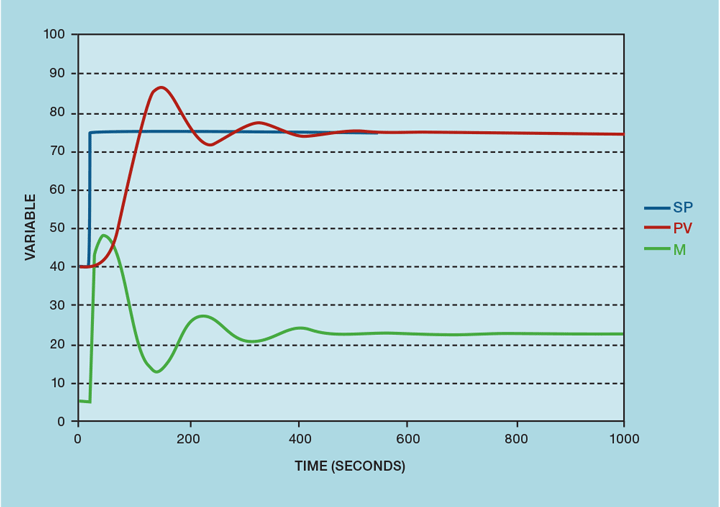

Before deciding on a tuning method, we first need to define what is meant by a well-tuned controller. What criteria do we use to assess this? The earliest published is the quarter decay ratio. As Figure 2 shows, following a disturbance, the process has a marginally oscillatory response with the height of each peak being a quarter of the height of the previous. This criterion was used by Ziegler and Nichols in developing their tuning method. Published in 1942, the method appears in almost every textbook and is included in many process control lectures. The method is now around 50 years beyond its use-by date. The instrumentation used at the time of the research would have been pneumatic. This is only an approximation to its modern digital equivalent. The method was developed by making process disturbances (known now as load changes) rather than set-point (SP) changes. This gives tuning that is far too aggressive for set-point changes. But perhaps the most significant change is that we would not today consider quarter decay a well-tuned controller.

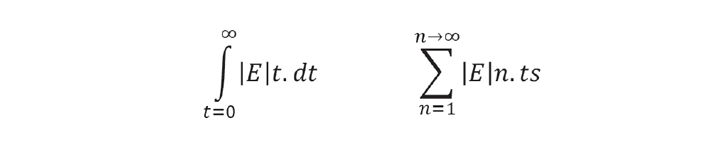

First appearing in the 1970s, a number of criteria, based on penalty functions, were used to develop tuning methods. The most enduring of these is the integral over time of absolute error (ITAE). In its analog and digital forms, it is defined as

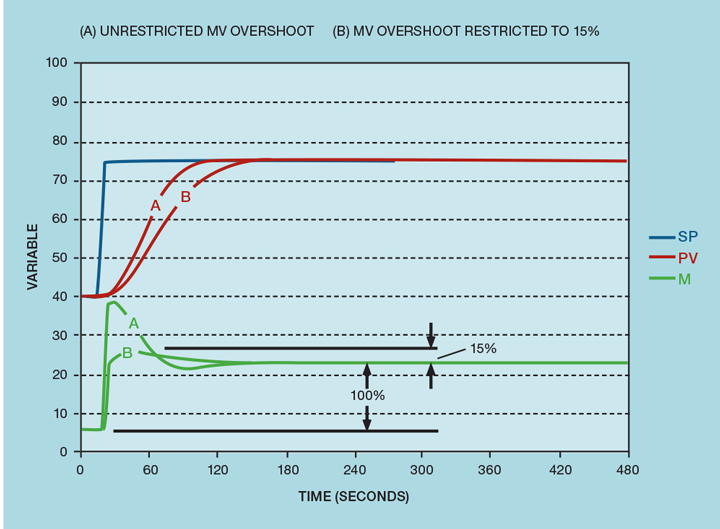

The time since the disturbance (t or n.ts) acts as a weighting coefficient. It discourages a tuning solution that gives a rapid initial response at the expense of long-term minor oscillation. Empirically it works well. Curve A in Figure 3 shows the result of tuning that minimises this penalty.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.