Oils & Fats: Essential Engineering

Qua Kiat Seng charts the evolution of vegetable oil production

ALTHOUGH I started my career as a Refinery Manager at Lever Brothers Malaysia in 1974, I was still fascinated to discover that vegetable oils, or more correctly seed oils, only became a major part of our diet in the last century. We know the ancient oils like olive oil, sesame oil, groundnut oil, coconut oil and palm oil were cultivated and appreciated for their flavour and aroma whilst animal fats such as tallow and lard were relied on for cooking. From the 1950s rape, soya, and sunflower oil underwent rapid production increases and by the late 1980s the dominant vegetable oils in world markets were soya, palm, sunflower and rape. So how did these vegetable oils find their way into your kitchen?

In the beginning

In 1900 American food chemist David Wesson introduced the first vacuum deodorising process for vegetable oils that became a standard for many decades. Deodorisation is a stripping process where steam is passed through hot oil at a low pressure to remove volatile components. Then in 1901 Wilhelm Normann introduced the hydrogenation of liquid oils converting it to solid fats of differing consistencies. These developments allowed cottonseed oil, that was inedible due to the presence of strongly-flavoured components, to be partially hydrogenated and be a replacement for animal fat in shortenings. In the US this was successfully marketed by Procter & Gamble as Crisco creamed shortening in 1911. This paved the way to the global production of margarine and vegetable shortening.

Trans fat

Partially hydrogenated oils (PHOs) tend to contain high levels of trans fat. In the 1950s, evidence of the negative impact of trans fat from PHOs emerged. Trans fats raise bad (LDL) cholesterol levels, thereby increasing the risk of developing heart disease and stroke. In 2015 the US Food and Drug Administration (FDA) finally determined that PHOs, the major source of trans fat in the food supply, were no longer “GRAS” (Generally Recognised as Safe).

Dual-temperature deodorisers

Since the late 1990s the food industry has started to reformulate away from trans fats, and some of the techniques included interesterification and the use of tropical oils such as palm and palm kernel oils and their fractions. Trans fat was still found in polyunsaturated oils like soya and rape due to thermal degradation during deodorisation at a high temperature of 230-260°C.

This was minimised by using dual temperature deodorisers that operate at two different temperatures, ie deodorisation for a longer time at lower temperature as well as heat bleaching and stripping of volatiles for a shorter time at higher temperatures.

3-MCPDE and GE

In 2010, 3-MCPD (3-MonoChloroPropaneDiol) and GE (glycidyl fatty acid esters) were detected in foods and vegetable oils. The European Food Safety Authority’s (EFSA’s) expert panel on contaminants found that 3-MCPD could pose risks to kidneys and testes (https://bit.ly/2XBEhT7). Glycidol (the parent compound of GE) is possibly genotoxic and carcinogenic.

On the premise that high temperature deodorisation is responsible, the dual temperature deodorisation was applied but it could only partly reduce 3-MCPDE (3-MonoChloroPropaneDiol Esters) and GE for palm oil. The quest for solutions was stepped up and in 2017, the Malaysian Palm Oil Board (MPOB) offered grants to mills and refineries to embark on research and development to reduce 3-MCPDE and GE in palm oil.

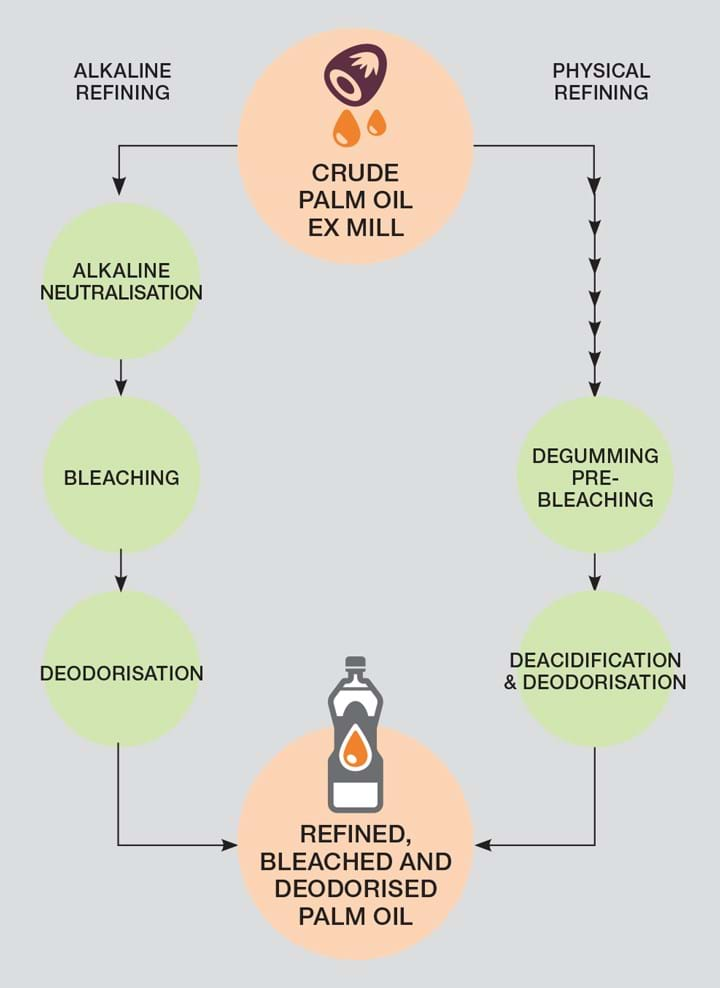

Refining of crude palm oil

To understand the solutions let’s look at the process of refining crude palm oil. Traditionally, the free fatty acids and red colour of crude palm oil are removed by neutralisation with caustic soda and earth bleaching before being deodorised. This is known as alkali refining.

In the 1970s as palm oil production increased it was found that if operated at a higher temperature the deodoriser could remove both the free fatty acids and the red colour of palm oil. It is a more efficient and cleaner process using less chemicals and earth. This is known as physical refining.

The precursors

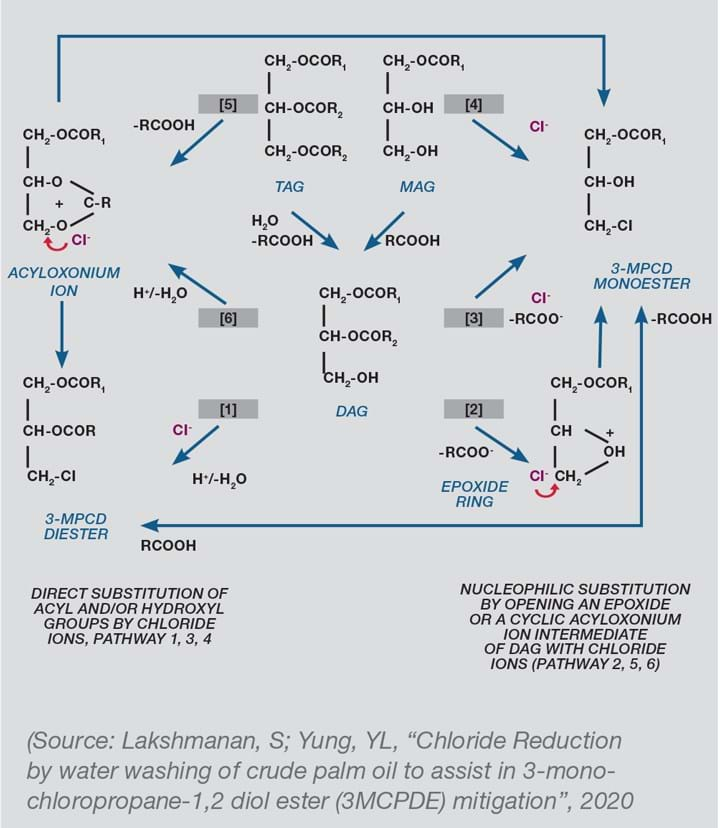

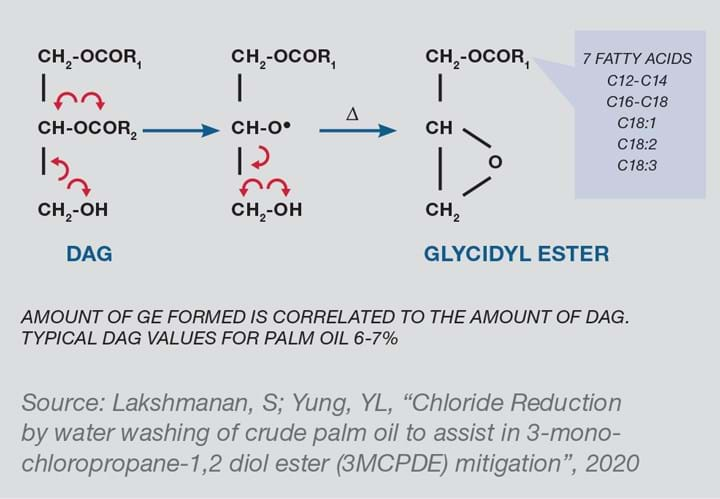

It was found that whilst 3-MCPDE and GE are formed at high temperatures the precursors are the presence of chloride ions and diacylglycerol (DAG) present in crude palm oil. Chloride ions come from fertilisers, pesticides, soil, diluting water, steam condensate, sludge and acidic conditions. The pathways for the formation of 3-MCPDE in the presence of chloride ion is now known.

Palm oil is a triacylglycerol (TAG) and upon harvesting due to the action of lipase enzymes the oil in the mesocarp of the fruit starts to break down into diacylglycerol (DAG), then monoacylglycerol (MAG). Also known is the pathway for DAG to form GE which is a ring compound.

The precursors exist upstream of the refinery so attention was paid to reducing the presence of chlorides and DAG in the plantations as well as the mills.

The solutions

Quite early on a few players were already able to resolve the issue and these included plantation companies that are fully integrated. Plantations changed the fertilisers used to reduce chloride in fresh palm fruit bunches (FFB). By ensuring that FFB is milled within 48 hours, DAG is reduced. At the mill, FFB sterilisation is carried out with steam without chloride and fresh crude palm oil is washed. At the refinery crude palm oil is washed if not already done so at the mill. The residence time and temperature during deodorisation is reduced optimally and additional process/equipment may be added.

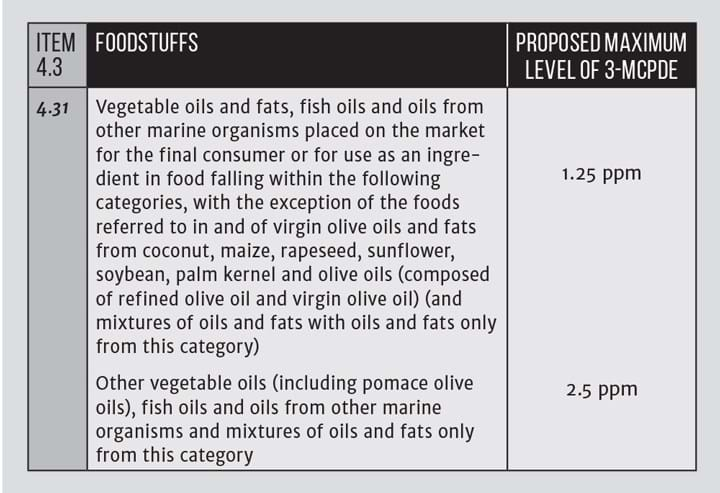

EFSA maximum levels of 3-MCPDE are as in Table 1.

Malaysia has adopted the European Commission’s proposal under Section 4.3.1 for two split maximum levels of 3-MCPDE and 1.0 ppm maximum level for GE (EU 2018/290) in vegetable oils and fats intended for food applications. This was due to come into force in January 2021.

As technology providers share their offerings, I review these (in alphabetical order).

ALFA LAVAL

Alfa Laval is one of the earliest players in the palm oil industry and has been in Malaysia since the 1970s. Alfa Laval invented the first disc stack separator in 1883 and has diverse applications of its centrifuges in the palm oil industry. Since 2017 it has sold 34 crude palm oil (CPO) washing systems to remove chloride. On average 7.39 ppm chloride in CPO is reduced to 1.25 ppm or 83% chloride is removed. Alfa Laval recommends early removal of chlorides at the mills and also the benefit from lower utility cost and easier effluent handling. If installed at refineries it gives the flexibility to receive CPO from various sources, and its centrifuge can handle high processing volumes. Refined bleached and deodorised (RBD) palm oil achieves 0.43 ppm 3-MCPDE.

Alfa’s PalmFlex refining route, which is widely used, starts with CPO washing, followed by degumming and bleaching, then deacidification/deodorisation and finally GE stripping without the need for post bleaching and post deodorisation. It can achieve GE below 0.5 ppm subject to GE content in feed. For PalmFlex the hot oil from the deacidifier/deodoriser is quench cooled rapidly to below 220°C and then stripped directly under strong vacuum and steam. Below 220°C, the rate of removal of GE is expected to be higher than the rate of formation. After stripping, fast cooling is immediately applied to obtain GE below 0.5 ppm, FFA below 0.03%, moisture below 0.03% and blandness/odourless RBDPO.

Alfa Laval is currently trialling a new technology it calls ZeroGE which is expected to reduce GE to below 0.1 ppm to cater for speciality high-end oils and fats. The technology will use a fixed bed catalytic reduction to break the GE ring. The results are expected later in Q1 this year.

DESMET BALLESTRA

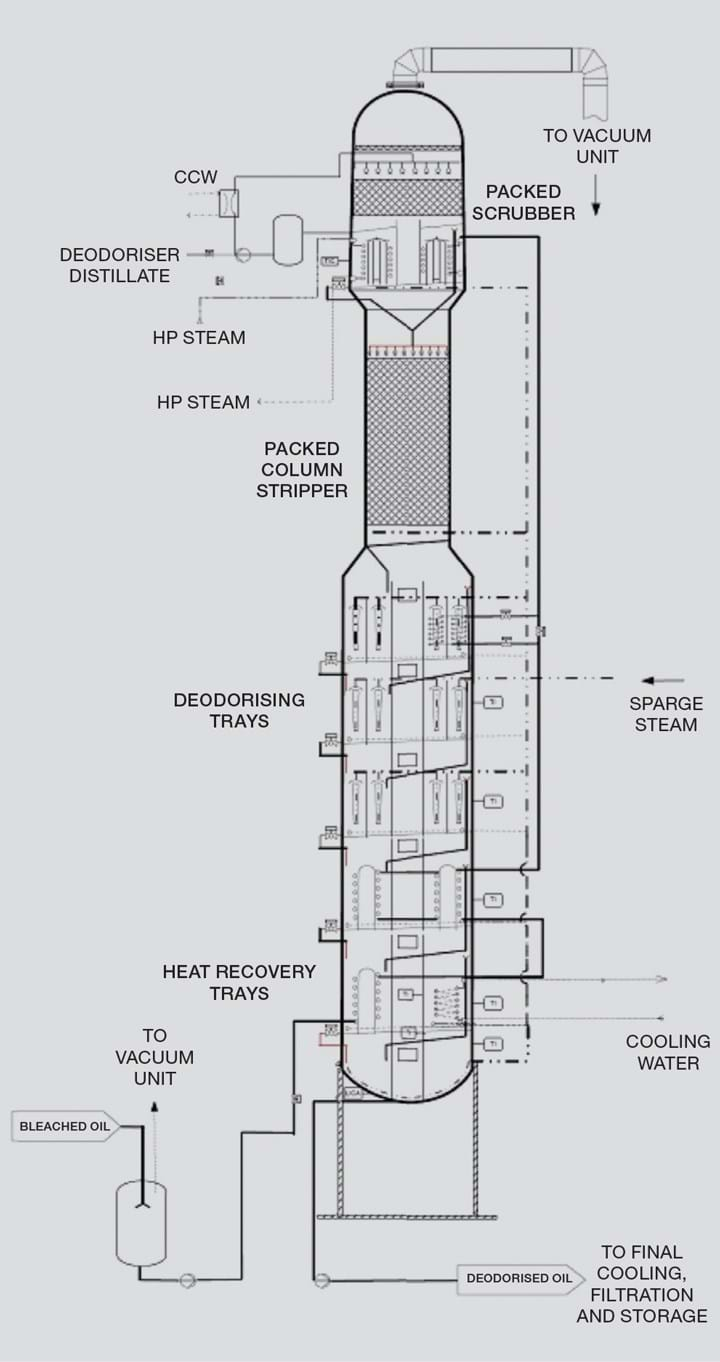

Desmet Ballestra was among the earliest technology providers to investigate and look for solutions to mitigate 3-MCDPE and GE. Trials conducted around 2015 on its dual temperature deodoriser Qualistock+ (see Figure 1) led to the need for washing CPO to remove chloride. It also recommended better quality CPO for food applications. When operated with a good vacuum (as low as 1 mbar) using its Sublimax 2G ice cooling condenser, the setup, when fed with good quality CPO, meets 3-MCPDE and GE limits. Difficult qualities of CPO may need double earth treatment, ie alkaline clays to remove MCPDE and acid activated earths to react with GE.

Desmet Ballestra currently recommends a single temperature deodoriser combined with a packed column post-stripper. Operating the deodoriser under standard conditions will result in a bland odour/taste, good shelf life, low FFA and light colour RBDPO. The post-stripper at deep vacuum with ice cooling condenser combined with fast cooling under vacuum will make GE <0.5 ppm possible. The attraction of the post-stripper is that it can be designed as an add-on to existing deodorisers. This is similar to the GE stripping of Alfa Laval.

JJ-LURGI

JJ-Lurgi was formed in 1992 in Malaysia with German engineering roots and a new generation of expertise in Asia. Lurgi experience in oil deodorising dates back to 1916.

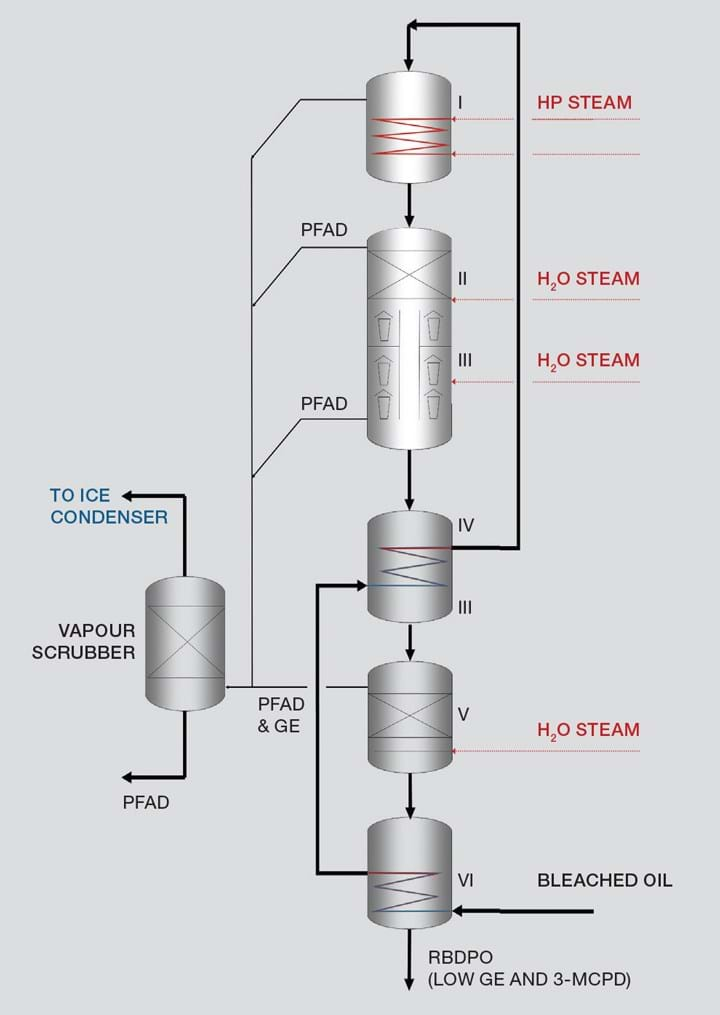

With understanding of the reactions going on in the refining of CPO, Lurgi’s design of Once Thru optimised refining uses a two-stage stripping of the bleached oil, one high temperature stage steam stripping/deodorisation (item II) followed by a lower temperature deodorisation (item III), and after a heat exchange with very short contact time (item IV) a high performance steam stripping for GE reduction (item V) and a final cooling under vacuum (item VI) to provide low GE and MCPD, with colour <2.5R and GE <0.5 ppm (see Figure 6).

Alternatively, optimised refining uses a 2 x Thru refining: bleached oil is deodorised at a high temperature followed by post-bleaching for GE removal, followed by low temperature polishing deodoriser to provide low MCPD and GE, with colour >2.0R and GE <0.5 ppm.

NOVOZYMES

Novozymes has already made inroads into the palm oil industry with the use of its enzymes for increasing oil extraction rate (2019) and biodiesel production (2014). Enzymes have been successfully used to remove organic chloride in the laboratory, though plant trials have been delayed due to the Covid-19 pandemic. Water washing is not able to remove organic chlorides. Organic chlorides are actually nonhydratable phospholipid mixtures with an aggregate of ions. Novozymes uses phospholipase enzymes to break these so that hydrolysed lipids are removed from the oil phase. This “dry degumming” process is carried out before the deodoriser and can achieve <1 ppm 3-MCPDE after refining.

SUMWIN SOLUTIONS MALAYSIA

This Malaysian company is relatively new, established in 2016. Its founder, however, is a veteran in the palm oil industry and in 1996 led the upscaling and commercialisation of red palm oil Carotino, a flagship brand for Malaysia.

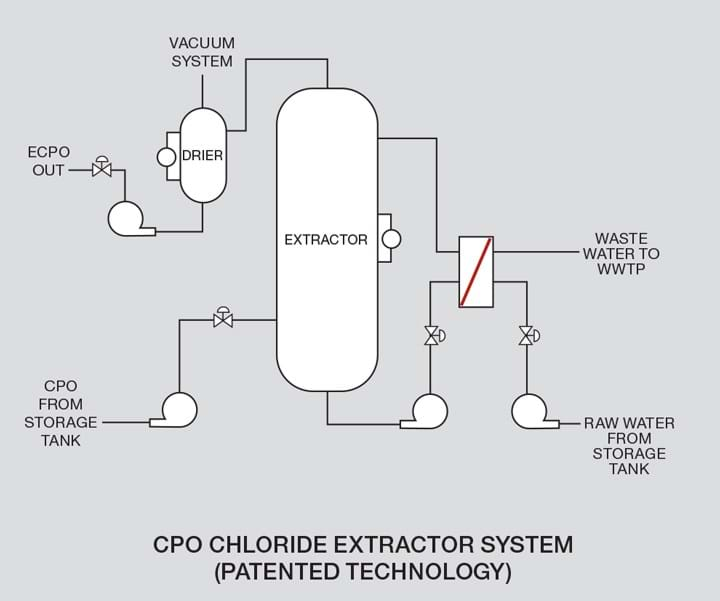

Sumwin offers a patented counter current liquid-liquid (L/L) extraction column for chloride removal in CPO. Given that DAG and MAG are emulsifiers, liquid-liquid extraction in a static non-turbulent column will be emulsion free during washing with nearly no oil in the waste water. A removal of 80% inorganic chlorides to <2 ppm is reported. The design allows for low maintenance.

For mitigation of GE, Sumwin customises to site requirements that includes deodorisation vacuum improvement. Together with the L/L extraction, this is meeting the EFSA requirements.

It also offers a GE stripper that operates at <1.5 mbar(a) and temperature between 230-240°C to achieve GE <0.5 ppm and FFA <0.05% in RBDPO.

In 2020, Sumwin’s technology won an IChemE Malaysia Award in the Palm Oil category.

Conclusion

It is heartening to see that in this decade the vegetable oil industry is able to come together and quickly solve issues that arise. The sectors – planters, millers and refiners – collaborated, albeit carefully. I have no doubt that the vegetable oil industry will be able to meet EFSA limits on 3-MCPDE and GE in 2021.

Wesson would not recognise his deodoriser today, which changed significantly in the 1950s to also be a deacidifer and heat bleacher. In the last 20 years Wesson’s deodoriser has seen even more changes very rapidly, as I outlined above. There is a high expectation on chemical engineers to solve problems in whatever industry, and we can do this well working with other engineers and scientists and others across the supply chain. The story of 3-MCPDE and GE bears this out for the vegetable oil industry.

The production of vegetable oils is still evolving and the benefits as well as the harm it can bring continues to unfold, requiring the timely intervention of many, including scientists and engineers. We have to always remain on our toes.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.