Kenneth Bingham Quinan and colleagues – An explosive start

Kenneth Bingham Quinan and a cohort of chemical engineers were key to the UK and its allies winning WWI, and forming IChemE, writes Trevor Evans

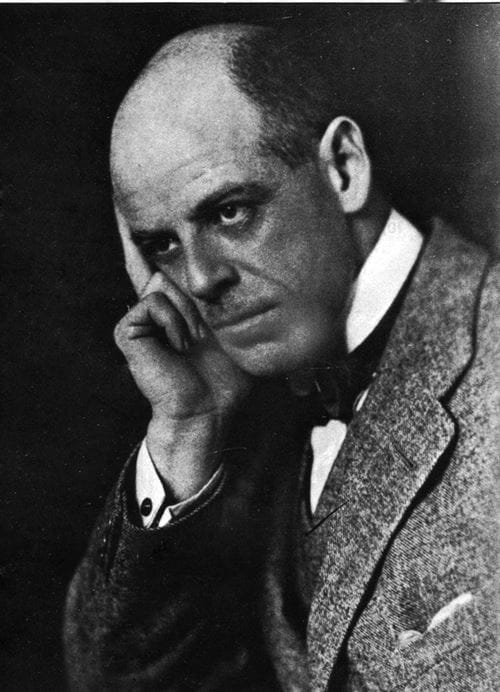

2015 marks the centenary of the Great Shell Crisis of World War I (WWI), in which the British Army was running short of munitions. The subsequent scaling up of the supply of high explosives and propellants became a major achievement of the embryonic chemical engineering profession under the leadership of Kenneth Bingham Quinan (pictured). Out of a recognition of these efforts, a momentum developed, leading to a wider recognition of chemical engineering as a profession and the establishment of IChemE in 1922.

It is the case that, notwithstanding the curse and suffering of war, conflicts stimulate the pace of technological development; be it weaponry and armour in the Middle Ages, the atom bomb at the end of World War II (WWII), or today’s electronic warfare. WWI – also known as The Great War (1914–18) – was no different, witnessing the development of aircraft, the invention of the tank as a fighting unit and the rapid improvement of the internal combustion engine, as well as new materials and much improved agriculture and food production.

The chemical industry also underwent massive change, in particular the production chain for intermediates used to manufacture munitions and in particular, propellants and high explosives.

Before the war, the British chemical industry was heavily dependent on imports, not least from a technically more advanced Germany, and raw materials were often at the end of long supply chains.

Britain’s disadvantage

Before the war, the British chemical industry was heavily dependent on imports, not least from a technically more advanced Germany, and raw materials were often at the end of long supply chains from the British Empire and South America. At the same time academic chemistry was seen to be a particular German strength and although chemical engineering was developing significantly on the other side of the Atlantic, where a home for the embryonic profession was provided by AIChE (founded in 1908), there were few indeed who described themselves as chemical engineers or practised the discipline in the UK.

To Britain’s further disadvantage, Carl Bosch had successfully scaled up Fritz Haber’s ammonia production process before the war started – an achievement the British failed to manage until after the war had ended.

Germany looked to have significant advantages over the UK as the Great War approached.

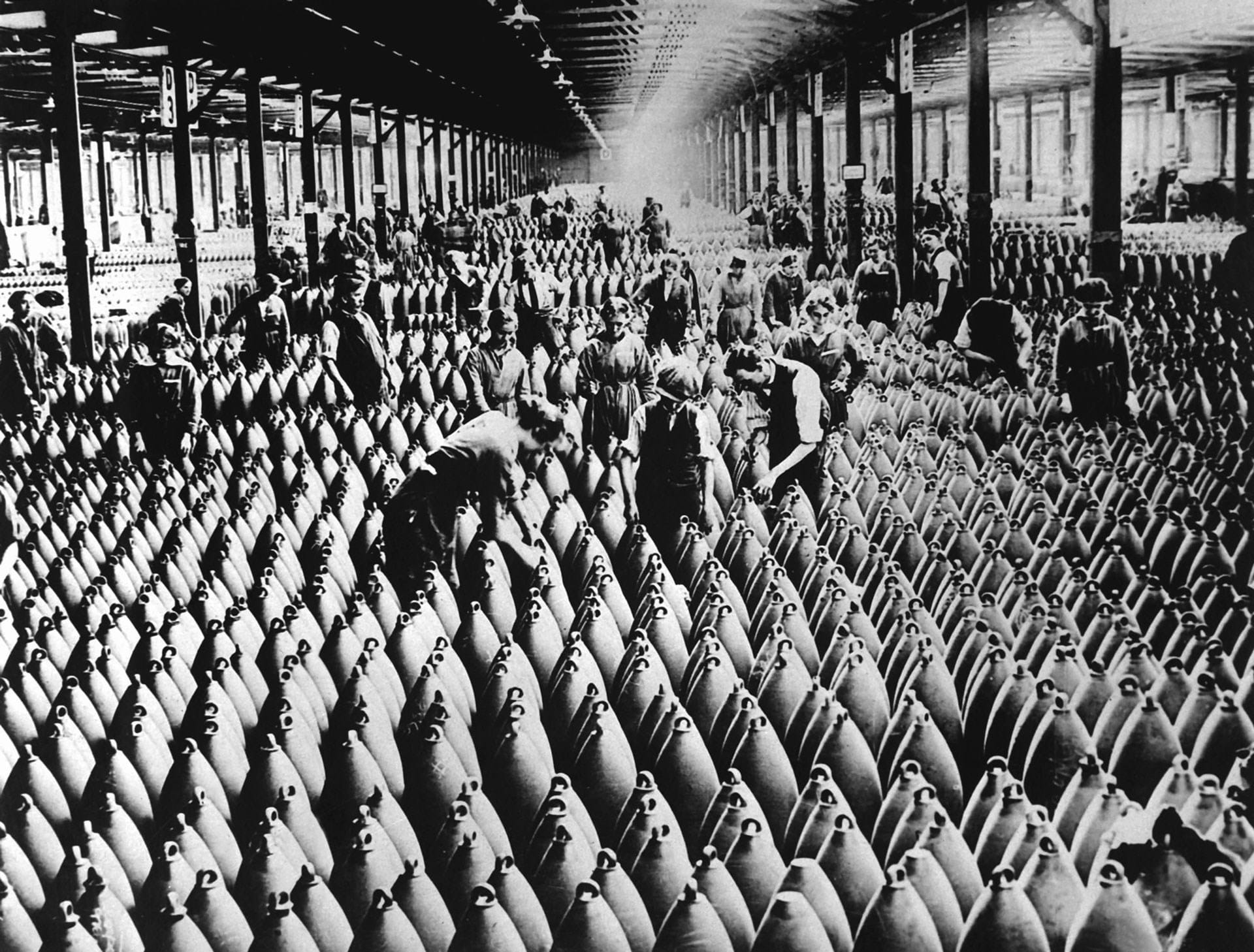

More, more, more

At its outbreak on 4 August 1914, prime minister Herbert Asquith appointed Herbert Kitchener to the War Office. Kitchener advised the cabinet that vastly more explosives would be needed; indeed the quantities of munitions required to conduct modern warfare were on a scale wholly different to any previous war in which the UK had been involved.

At the Battle of Neuve Chapelle in March 1915 more shells were fired in a 35-minute bombardment than in the whole of the Boer War. As Field Marshall Sir John French, the commander of the British Expeditionary Force put it, as the war drifted to a static stalemate, “the problem set is a comparatively simple one – munitions, more munitions, always more munitions.”

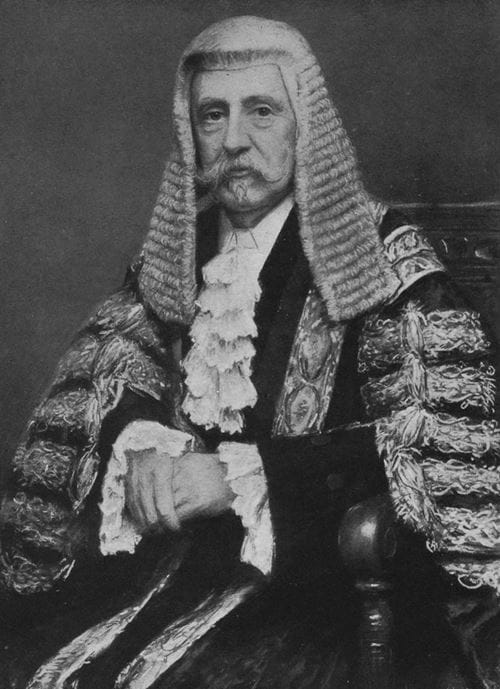

A War Office advisory committee on explosive services (including the internationally-recognised explosives expert, and later IChemE president, William Macnab) met for the first time on 16 November 1914, under the chairmanship of a 70-year-old law lord, John Fletcher Moulton. This appointment was to prove to be an inspired choice.

Lord Fletcher Moulton KCB GBE

Moulton was an extraordinary man, with the reputation of being one of the cleverest in the country. He was born in 1845, the third son of a Wesleyan minister, and was educated at Kingswood, a Methodist establishment. He was a gifted student and excelled at mathematics. He came out top in all England in the first Oxford and Cambridge local examinations. Following a glittering career at Cambridge Univeristy, he was set on a career in law, but found time to work with William Spottiswoode, the president of the Royal Society, on electrical discharges in rarefied gases, for which he was elected Fellow of the Royal Society (FRS) in 1880.

At the bar, Moulton’s legal cases had often involved scientific and industrial matters, notably relating to a dispute between Nobel’s and the government on cordite production, sundry dyestuffs cases and the advice he gave in respect of the Marconi patent.

His contributions to public service included, in 1912, becoming the first chairman of the Medical Research Council and after the war leading the reorganisation of the British dyestuffs industry, merging Levinstein and British Dyes. Against the tradition that a judge could not hold a commercial post, he served as the first chairman of the new British Dyestuffs Corporation. But it is for his wartime service as director general of explosives supply that he is most remembered with gratitude by his country.

After the war, Moulton used his advocacy and directed much of his energies to chemical engineering and the need for suitably-trained professionals in this new discipline. He spoke widely on the topic and lent his weight and authority to those championing an institution and the provision of suitable academic training. But for his sudden and unexpected death in March 1921, he would undoubtedly have played a leading role, a year later, in bringing the new institution into being.

In Moulton’s memory, in 1929, IChemE established the award of the Senior and Junior Moulton Medals, presented each year for the most meritorious papers published by the Institution.

The committee’s life was short lived. After ten days of meetings, Moulton submitted his report, proposing that an executive should be established to “run explosives production” for the nation. Moulton and a small staff took up their quarters at the offices of the Institution of Mechanical Engineers and set up what was to become the Explosives Supply Department (Department A6 of the War Office), with Moulton as director general. At the same time, the Defence of the Realm Consolidation Act was passed, empowering the government to seize any factory or its output. For example, the entire output of coal tar was commandeered.

Early decisions were taken to maintain production of picric acid (lyddite) but to concentrate expansion on the preferred new high explosive TNT, in order to maximise total supply of high explosives. The limiting factor was the availability of toluene, produced from coal tar and Borneo petroleum. Even if the dye industry was to be denied any coal tar, the total amount of toluene that could be produced with maximised yield was still insufficient to meet demand. Moulton’s solution was to propose that TNT be mixed with ammonium nitrate. Against the wishes of the military, Moulton persuaded Kitchener to support his proposal, and the mixture, known as amatol, was adopted for the army. Even if he had done nothing more, by this decision alone Moulton performed a service of inestimable value to the war effort.

But this left the question as to how could production be ramped up for both propellants (cordite) and high explosives (TNT). Scaling up has become recognised as one of the defining contributions made by chemical engineers to industrial production, and it was to a chemical engineer that Moulton turned.

Kitchener advised the cabinet that vastly more explosives would be needed; indeed the quantities of munitions required to conduct modern warfare were on a scale wholly different to any previous war in which the UK had been involved.

Propelled from South Africa

Kenneth Bingham Quinan (always known as “KBQ”) was a 36-year-old, self-taught American chemical engineer and general manager of the de Beers’ Cape Explosives Company’s works at Somerset West, South Africa. The works were the largest in the world, having been built to break the monopoly of the Nobel Dynamite Trust.

On 19 December a cable was sent to Quinan asking him to join the war effort. He sailed the same day from Cape Town arriving in London early in 1915 to take up the leadership of the factories branch of A6. His employer, de Beers’, was compensated for the loss of his services to the tune of £4,000/y, the equivalent of £250,000 today. For a long period after his arrival, the treasury sniped at this cost and the successive renewals of his secondment.

Quinan was a necessary breath of fresh air in a British system beset by hierarchies and prescribed ways of doing things. His robust style and language, while not unfamiliar to the Australian and South African recruits he brought into the Factories Branch, could upset staid British sensibilities. When addressing assembled works managers, he told them not to turn their plants into “bloody constipated caterpillars”. Rather, production had to be doubled, redoubled and then redoubled again. Writer Arthur Conan Doyle described him as having “the drive of a steam piston”.

As much as Quinan was to become known as a brilliant organiser in wartime conditions, he was also a hands-on designer offering ideas for process and plant improvement. His first task was to complete the design and construction of a new huge TNT plant to be built at Oldbury, using RC Farmer’s Woolwich process, which obviated the need for oleum. Quinan’s method has been described as meticulous.

According to Macnab, “each workshop was planned with a ledger of chemical inputs and outputs, displaying every step in his calculations. Next he determined the heat produced or absorbed and the needs for water, electrics, compressed air and the like. Blueprints for buildings and diagrams of reaction vessels were annotated with elucidations”.

Quinan was a necessary breath of fresh air in a British system beset by hierarchies and prescribed ways of doing things... he was to become known as a brilliant organiser in wartime conditions, he was also a hands-on designer offering ideas for process and plant improvement.

In just 100 days the plant was started up, and the plant adjacent to the Chance and Hunt works was nationalised and fell under Quinan’s authority. William Calder, the general manager of Chance and Hunt, was given responsibility for the works.

Quinan was a formidable task master. On receiving a report about an underperforming Grillo plant for sulphuric acid production, he wrote to the works manager: “In conclusion, I should like to state that quite frankly that in my opinion the character of the contact process is not understood by any member of your staff…in bringing this memorandum to a close, I should like to state that the foregoing comments and suggestions are put forward with a great deal of diffidence and disinclination on my part, for the reason that it is a thankless and unpleasant task to be asked to patch up and tie together with string, a plant on which a huge amount of money has been spent – apparently without any regard whatsoever to the fundamental principles of mechanics, construction, chemical practice, and thermodynamics upon which the process for which the plant was designed absolutely depends!”

At the same time, Quinan was organising the dismantling of the Rotterdam distillation units owned by Royal Dutch subsidiary Asiatic Petroleum and having them re-erected at Barrow-in-Furness and Avonmouth. This transfer led to greatly-enhanced toluene production via fractionation of Borneo crude, doubling at a stroke the total pre-war toluene capability.

Next, Quinan turned to the design of new major national factories, notably Sandycoft, Queensferry and Gretna. These enormous extended factories – the largest, to this day, ever completed in Europe – were designed to produce weekly 600 t of TNT, 15 t of tetryl and 200 t of nitrocellulose at Queensferry, and 800 t of cordite at Gretna.

Crisis time

At this stage political turmoil took over in the country as news of a desperate shortage of shells was leaked to The Times. Asquith’s Liberal administration fell to be replaced by a coalition with the Conservatives, and the chancellor, David Lloyd George, moved to the area of greatest national priority, establishing the new Ministry of Munitions of War. At the same time Douglas Haig replaced John French as commander in the field.

A6 was transferred to the new ministry, becoming the Explosives Supply Department (ESD). Frederic Nathan – who had in some respects been Quinan’s counterpart in the Admiralty and who had designed the naval Holton Heath explosives factory, in Dorset – joined the Department, becoming responsible for propellant supplies. Nathan, who had an earlier military career, had previously been superintendent of the Royal Gunpowder Factory at Waltham Abbey, before becoming general manager for Nobel’s at Ardeer.

The Queensferry and adjacent Sandycroft operations came on line early in 1916, followed by Gretna some months later. The Shell Crisis was being progressively overcome, not however before the Asquith government fell, with Lloyd George succeeding him as prime minister and Montagu, later Addison, and finally Churchill leading the Ministry of Munitions.

It is worth pointing out the size and scope of the operations at Queensferry, which included major facilities for the production of nitric and sulphuric acid and treatment of spent acids. It cost £4.15m to build, and its total production was valued at £19.8m, substituting for £33m of imports at American contract prices. The workforce peaked at 7,000 – of whom 2,500 were female – on a 120 ha site. During all of the wartime operations only four people were killed on the site.

At Gretna, two townships (Gretna and Eastrigg) were constructed. The factory itself stretched for 19 km and the complex covered an area of nearly 3,642 ha. A coal-fired power station was built for the townships and factory, and 10m gallons/d (45m l/d) of water were treated and filtered. Of the 16,500 workers over 11,000 were female. The production of cordite at Gretna was more than that of all other factories across the Empire combined.

Safety record

It is estimated that around 600 munitions workers were killed in industrial accidents during the war, notably 134 workers at Chilwell Shell Filling Factory following a TNT explosion, 140 at Faversham when a TNT store went up following a fire, and 73 at Brunner Mond’s production facility at Silvertown.

The safety record of Quinan’s plants fared better (three at Gretna and four at Queensferry) and are a tribute in great part to his design skills. That said, Gretna had its own hospital and occupational ill health was a significant problem.

By the end of the war some 32 factories were under the direct control of the ESD. Government paid the startup and construction costs for 218 more but they were operated by private industry with output taken at a guaranteed price. For example, in the case of ammonium nitrate for mixing with TNT to make amatol, 2,000 t/week were required – coming from two Brunner Mond factories in Cheshire and HM Factory Swindon. The ESD and Quinan’s department became intimately involved in all these operations and others involving calcium nitrate, ammonium perchlorate, phenol for the remaining picric acid plants, acetone, soap operations for glycerol, and much of distilling for industrial alcohol.

In the later stages of the war, responsibility for chemical warfare supplies – such as mustard gas, chlorine and phosgene – passed to the ESD, and Moulton and Quinan faced some criticism from its minister, now Winston Churchill, concerning production and supplies. It was the case that Moulton viewed gas, as a weapon of war, with some distaste.

The degree of scaleup and expansion of supplies of high explosives and propellants during the war is captured in the chart.

Winning the war

While perhaps properly, the greatest honour and the collective memory of the nation falls to those fought the war at the front, at sea and in the air, it is not a claim too far that without the contribution of those who turned around the manufacture of propellants and explosives in 1915, the war could not have been won.

For his services in the war Quinan was offered, but as an American citizen turned down, a knighthood. He had, however, been included in the first list of 17 names to be awarded the newly-instituted decoration of Companion of Honour (CH) in 1917, for “special work in connexion with the Explosives Supply Department of the Ministry of Munitions”. Chemical engineering was indeed special work!

Quinan also received the French Croix de Guerre and the thanks of the House of Commons. From the government, in 1917, he had received a ‘gift’ of £10,000. Today this is equivalent to just short of £0.5m, although in terms of economic status or power, the award is more comparable to between £2–3m. Hansard records the thanks given to him in the House of Commons, and as The Times recorded of his achievements: “It is hard to point to anyone who did more to win the war than Kenneth Bingham Quinan”. At one point during 1916, Quinan had turned down the chance to return to the US to build a series of factories on a commercial deal offering 0.25% of the capital employed, estimated to offer the prospect of £50,000/y.

Quinan’s legacy was, however, more significant, than a series of papers and sites of interest to industrial archeologists. He had inspired a group of men, not least Lord Moulton, as to the importance to the nation of chemical engineering.

Beyond papers and sites

His job done, and notwithstanding offers to undertake roles in industry and government service, early in 1919, Quinan returned to South Africa and resumed his role at Somerset West. Subsequently he left industry, married a girl half his age and took up fruit farming, only to be called back as an advisor to the South African government on explosive matters at the commencement of WWII.

Today Quinan’s papers are gathered together in some 288 dense files of correspondence, designs, flowsheets, a dozen or more patent applications, block diagrams and plans, at the National Archives in Kew. The decaying remains of one of his personal process improvements, the Quinan Stove for the drying of guncotton by blowing dry air through fluidised beds, can still be found at Waltham Abbey and Gretna. This innovation by itself improved drying times and, by reducing inventory, improved safety, while upping the throughput of a cordite factory by some 50%.

Quinan’s legacy was, however, more significant than a series of papers and sites of interest to industrial archeologists. He had inspired a group of men, not least Lord Moulton, as to the importance to the nation of chemical engineering. He had always seen the explosives department as being a “great educational institution” for those around him. His notebooks were published by Macnab and HW Cremer (who had worked on TNT at both Oldbury and Queensferry) as textbooks for training chemical engineers.

During the latter part of the war, and with increased recognition of chemical engineering, the Society of Chemical Industry established its Chemical Engineering Group as a meeting point for discussion about chemical engineering matters. Now Macnab and others began to explore the idea of establishing a professional qualifying body for chemical engineers in the image of the other engineering institutions. Discussions were held with other institutions covering chemistry, mechanical and civil engineering to explore options, but a momentum was developing for courses of instruction for chemical engineering and a professional institution.

The contribution of Quinan’s men and contacts in these developments was central. In particular Moulton was convinced of the importance of chemical engineering to the future of the British chemical industry. In public lectures, notably at Sheffield and University College London, he called for new courses of instruction. As a law lord, Fellow of the Royal Society, honorary member of the three largest engineering institutions, and first chairman of British Dyestuffs Corporation, he carried much weight. But in March 1921, following a session in the House of Lords, Moulton’s valet found him dead, in bed.

A year later, in 1922 the embryonic Institution of Chemical Engineers came into being.

Truly this was a leadership of a new profession, forged in times of war...a bond amongst a group of civilian engineers... which they took forward in their work to establish a new 20th century brand of engineering.

Early leaders

An examination of the roll of presidents of the new institution is instructive in terms of the enduring influence of Quinan and the legacy of the wartime Ministry of Munitions on the new body and its educational ambition. Quinan himself was elected the first vice president, but this was to be little more than an honorary, corresponding role. In the event, IChemE’s first president was Sir Arthur Duckham, who had chaired the (industrial) Advisory Committee to the Ministry of Munitions and had served as deputy comptroller of the Munitions Inventions Department.

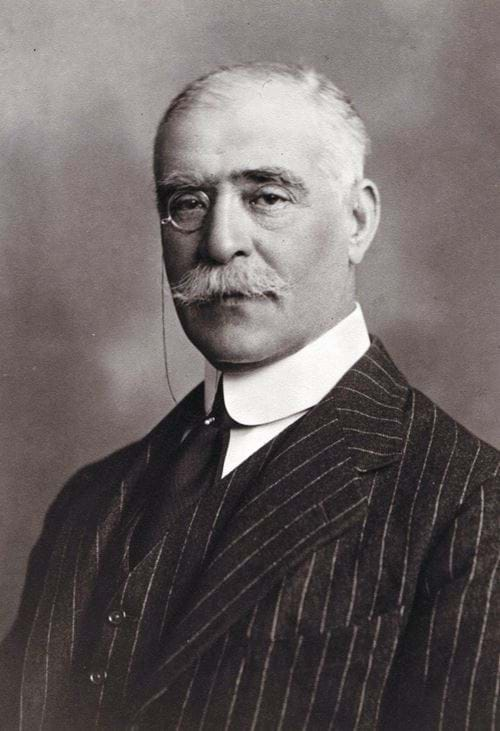

He was in turn succeeded by Sir Frederic Nathan, notable in particular for his experience in wartime as director of propellant supplies in ESD, and the architect of explosives production for the navy at Holton Heath.

Sir Frederic Nathan KBE

One of a remarkable set of brothers of Jewish ancestry, Frederic Nathan played a major role in planning and establishing IChemE and went on to serve as its second president. He was born in 1861, the eldest of five brothers and two sisters. He was privately educated (it being the case that leading English public schools at the time were not welcoming of Jewish students) before joining the Royal Artillery in 1879, rising eventually to the rank of Brevet-Colonel. From 1886 his army career focussed on ordnance, leading to his final post as superintendent of the Royal Gunpowder Factory, Waltham Abbey.

Nathan was jointly awarded the patent for the Nathan-Thomson-Rintoul nitrator/separator for the production of nitroglycerine and was responsible for the first production batches of cordite. He was knighted in 1906, retiring from the Army in 1909. He was next appointed general manager of Nobel’s Explosives Co’s works at Ardeer, continuing to work on scientific developments with William Rintoul. On the outbreak of war, Nathan’s energies were directed towards the building of a major TNT plant for Nobel’s at Pembrey, near Llanelli (later Royal Explosives Factory Pembrey). In February 1915 Nathan was appointed advisor on cordite supplies to the Admiralty and with Churchill’s support designed and built the Royal Naval Cordite Factory at Holton Heath, Dorset.

When as a result of the shell crisis, the naval and military munitions efforts were amalgamated under Moulton, Nathan was appointed director of propellant supplies, becoming responsible for the provision of raw materials for propulsion explosives. This meant that he took control of the soap and distillery trade of the country.

Nathan was also responsible for introducing Chaim Weizmann (later to be the first President of Israel) to Churchill and subsequently to Lloyd George. Weizmann had been summoned to the Admiralty to meet Nathan to discuss his fermentation process for the production of acetone from starch/maize, to overcome severe supply shortages. The process was taken up and Weizmann was appointed as chemical advisor to the Ministry of Munitions on acetone production.

Along with William Macnab, Nathan became one of the principal advocates for an institution of chemical engineers in the post-war period. He encouraged Moulton to give his lectures on the need for a new branch of engineering to ensure the future health of the British chemical industry. He also played an important role in setting out the educational requirements for the new discipline, with IChemE setting its own examinations. He was elected president in 1925 and continued to contribute to the Institution and its influence until his death in 1933.

Thereafter, William Calder, who had taken over responsibility for the Quinan-designed factory at Oldbury succeeded as president in 1931. William Macnab, who had served on the very first Moulton committee and had worked tirelessly for an institution for chemical engineers, was elected president in 1934. His successor Herbert Levinstein, whose company merged to form British Dyestuffs Corporation, had been much engaged in producing intermediates for Quinan’s explosives factories.

William Cullen, who became president in 1937, was an explosives man through and through, from Nobel’s in Ardeer and Modderfontain in South Africa, returning to the Ministry of Munitions in 1915, to lead the major (unfulfilled) smokeless powder project. In the same year, F Heron Rogers (president 1939/40) had been withdrawn from the front to work on chemical and explosives installations, including the Colnbrook guncotton plant.

The connection with Quinan continued through to post WWII, when Herbert Cremer was elected president in 1947 (Quinan died in January 1948). Cremer, who had been at the Royal Arsenal at the start of WWI, worked successively at Oldbury and Queensferry on TNT, before moving to ESD as Quinan’s executive assistant. Together with Macnab, he had edited Quinan’s design guides as educational materials for training chemical engineers. In 1951/2 and 1954/5, Sir Harold Hartley provided the last direct link back to Quinan in the presidential succession, having been the controller of the Ministry of Munitions Gas Warfare Department, for which Quinan and ESD assumed responsibility for production in the latter phases of the war.

Truly this was a leadership of a new profession, forged in times of war. Their common experience in the Ministry of Munitions, led in turn by politicians Lloyd George, Addison and Churchill, forged a bond amongst a group of civilian engineers, akin to regimental service on the front line, which they took forward in their work to establish a new 20th century brand of engineering.

Originally published in May 2015

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.