Scientists demonstrate powdered vaccine can break the cold chain

SCIENTISTS have taken a step forward in breaking the so-called vaccine “cold chain” by creating a powdered vaccine that has prompted an immune response.

Currently, vaccines must be refrigerated before use – from manufacture, through transport and storage. They must remain between 2–8°C or their proteins unravel and the treatment no longer works. Maintaining this cold chain is a significant challenge in developing countries where power can be intermittent or cold storage is simply unavailable.

According to the World Health Organization (WHO), 19.4m infants did not receive routine life-saving vaccinations in 2018.

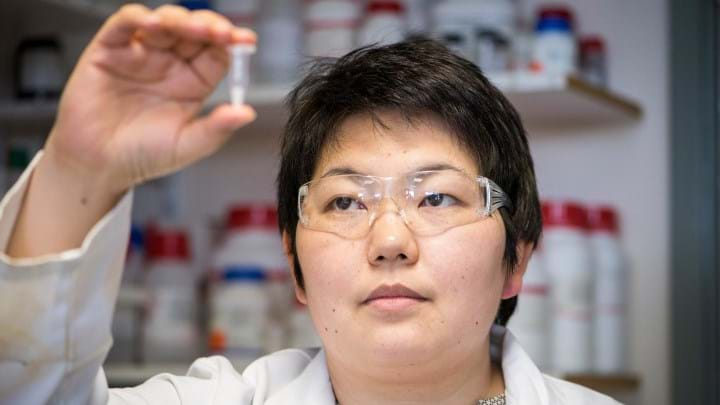

Chemist Asel Sartbaeva from the University of Bath, UK is leading a project to break this cold chain by encapsulating vaccines in a silica shell, transforming the liquid treatment into a powder that prevents the vaccine degrading. Her team had previously shown in the lab that this ‘ensilication’ process protects proteins when heated for five hours at 100°C or when stored at room temperature for three years. In their latest study, Sartbaeva and colleagues transported ensilicated and regular samples of a tetanus antigen some 300 miles from Bath to Newcastle.

They report that when injected into mice, the ensilicated version (after removal from its silica shell) triggered an immune response, while the regular vaccine did not because it had degraded outside the cold chain.

Sartbaeva said: “This is really exciting data because it shows us that ensilication preserves not just the structure of the vaccine proteins but also the function – the immunogenicity.”

“This project has focussed on tetanus, which is part of the DTP – diphtheria, tetanus and pertussis – vaccine given to young children in three doses. Next, we will be working on developing a thermally-stable vaccine for diphtheria, and then pertussis. Eventually we want to create a silica cage for the whole DTP trivalent vaccine, so that every child in the world can be given DTP without having to rely on cold chain distribution.”

The team reports that while ensilication is a suitable method for protein preservation, it currently requires laboratory conditions and a dialysis step to release the vaccine from its silica shell. This would not be suitable in real-world clinical conditions, particularly in low-income countries. So the team is working towards alternative release methods including an all-in-one device that it hopes to prototype in the near future.

Sartbaeva estimates that ensilicated vaccines could be used for humans within 5–15 years, and hopes to use the technology to protect other protein-based products including antibodies and enzymes.

Nature: http://doi.org/d252

To learn more about the technology and the engineering challenges involved in its development, read the article Sartbaeva wrote for The Chemical Engineer.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.