IChemE Matters – April 2024

Celebrating excellence

Nigel Hirst, IChemE president

ONE of the privileges of being IChemE president is being the first to congratulate those who are honoured by the Institution, so I was delighted to acknowledge the eight individual and five group winners of our 2024 IChemE medals and prizes earlier this month. The chemical and process engineers who are helping to shape the world with their groundbreaking work, exceptional expertise, and dedicated progress towards addressing our global challenges are setting an inspiring standard of excellence for us all (see here).

The steady rollout of our new initiatives continues, with the UK pilot of the Young Engineers Awards for Innovation and Sustainability (YEAIS) launching in March. This competition is a fantastic opportunity for members aged 18-25 to put forward their ideas on how to contribute towards IChemE’s Priority Topics, and a platform for us to champion the talent and innovation of student and early-career chemical engineers.

Over 1,000 members have now joined IChemE Connect and the platform has received a very positive response from those who are already contributing. This dynamic space has enormous potential for networking and knowledge exchange. To support this growing online community, we are beginning to introduce dedicated communities for member groups and special interest groups so that members can interact with each other on topics relevant to specific locations or subjects – so do come and join the conversation at www.icheme.org/connect

The pilot phase of our career and development mentoring initiative is underway, with 12 matches now confirmed between mentees and mentors, and more in the pipeline. Keep an eye out for its launch to the wider membership later in the year.

I’m looking forward to giving a keynote at ChemUK, as these events are always great opportunities for me to meet and talk to IChemE members and non-members. ChemUK takes place at Birmingham’s NEC on 15 and 16 May, and with hundreds of specialist exhibitors and expert speakers it’s an ideal event for networking and learning about innovation. Don’t forget to register for your free visitor badge at www.chemicalukexpo.com

I always welcome any feedback, and value any input or ideas you would like to share – you can contact me at president@icheme.org

Sign up for our circular economy webinar series

Jonathan Seville, Priority topic lead for responsible production, innovation and industry

WE have become familiar with the term “circular economy” and the ideas of reuse, remanufacturing, and recycling. It is clear that decision-making in this field requires the system-level understanding which chemical engineers can bring.

As part of IChemE’s commitment to sustainability, the Learned Society Committee in conjunction with the Special Interest Groups has launched a monthly series of webinars. These address the principles and practice of the circular economy. The key questions to answer are: When is circular sustainable and when is it not? How can we measure our success in terms of environmental benefit? What is the relationship between “flows”, including the quantity of recycled material, and “stocks”, that is the quantity of material held (usefully or otherwise) in the economy? What are the barriers to be overcome and what does all this mean for labour and for human wellbeing?

Adisa Azapagic, editor of IChemE journal Sustainable Production and Consumption, started us off in February with the webinar Systems, Life Cycles and the Circular Economy. She showed the essential use of life cycle analysis in decision-making. If you missed it, you can watch the recording on IChemE’s website.

We have four more planned. Next up is Jin Xuan of the University of Surrey who leads the UK Interdisciplinary Centre for Circular Chemical Economy (CircularChem). The centre was established in 2021 to kickstart the transition of the UK’s £32bn (US$40.7bn) chemical industry into a circular system. Speaking on the day that TCE went to print, Xuan discussed the barriers and solutions to achieving this transition.

18 April: Jim Goddin of thinkstep-anz will focus on the crucial metrics and benchmarks needed to assess circularity within the chemical engineering sector and beyond.

16 May: Food and Drink SIG committee member Seamus Higgins of the University of Nottingham, who has set up processes and systems for companies including Nestlé and Premier Foods, will discuss the importance of circular thinking in the food and drink sector.

20 June: Piero Salatino and Roberto Chirone of the University of Naples present their work, carried out with industrial ecology expert Roland Clift, on the analysis of remanufacturing and recycling as process systems. They will explore the wider impact that chemical engineers can make.

Register for the webinars and watch recordings here: https://www.icheme.org/circular-economy-webinars

Your definitions of ChemEng

Last issue, we asked you: how do you define a chemical engineer? One reader replied “Defining ‘a’ chemical engineer is actually complex, and needs more than two paragraphs.” Unfortunately, you don’t always get that much space or time to capture and hold someone’s attention. Here are a selection of your pithiest replies:

“A chemical engineer is a chemist whose lab bench is the size of a house.” David Threlfall

“It is turning raw materials into useful products – so a chemical engineer has probably touched all of the manufactured things you use every day in some way.” Yasmin Ali

“Chemical engineering is the process of turning raw materials to finished products considering energy and material conservation, sustainability, and environmental impact.” Nasiru Mohammed

“Managing flows and transformations of materials and energy. Conventional chemical engineering does that inside pipes. Whereas industrial ecology does that in the economy.” Roland Clift

“I find the best way is by picking an object and then talking about how it was made and what the involvement was of chemical engineers. I was in a school giving a talk recently and picked up a water bottle. This allowed to me talk about water and water treatment, and also the plastic bottle and the source of its raw materials.” Vince Pizzoni

“I often use an example of baking a cake, something most people can identify with. I take them through the “unit operations” – sorting, weighing, sifting, mixing, pouring, heating, cooling – of making one cake in a day. I then position chemical engineers and others as the people who work out how to build a factory that can make 10,000 cakes (or more) in a day.” Richard Boocock

“Making things. Kitchen chemistry at a large scale. Tonnes not teaspoons.” Howard Harris

“A chemical engineer is integral to the provision of a variety of products and systems which touch our everyday lives. Think of healthcare, energy, food and beverages, cosmetics, environment. From the toothpaste you use every day to the life-saving medication administered to your loved ones. Chemical engineers are vital to life as we know it.” Claire McGonagle

“We make things, and we make things more efficient.” Euan Munro

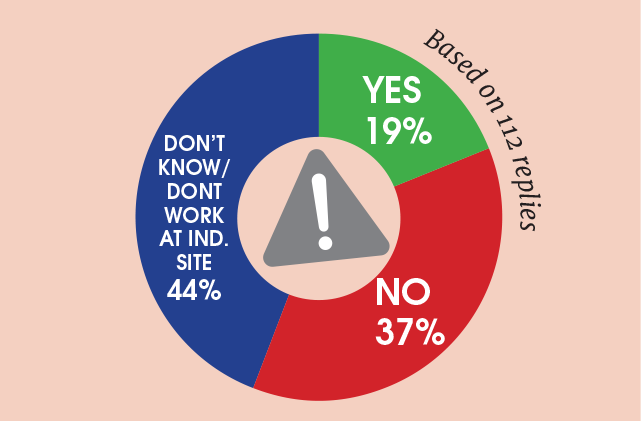

Last issue, we published articles from safety experts on the risks that natural hazards present to industrial sites as climate change drives more extreme weather.

We asked our feedback panel members: are you concerned that natural hazards have not been adequately considered at your site?

“Many of the industrial clients I am working with are implementing protections on their sites.” IChemE Fellow

“Natech is a really bad name for this, I think it needs a rebrand in order to have the impact it definitely needs!” Chartered member

“I see natural hazards increasingly being considered as part of the discussion in HAZID/HAZOP/OPHR and while this is encouraging, it probably needs to be more consistent and systematic.” IChemE Fellow

“Given the uncertain nature of future natural hazards, would we expect to see insurance contracts start to list maximum conditions (temperature, rainfall, wind speed) beyond which the insurance contract is no longer valid?” Chartered member

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.