The Story of Oil 1822–1922

Martin Pitt continues to look at the history of chemical engineering and IChemE

IN 1822 the oil industry was in full swing. Around the world, the smelly process of heating up whale blubber to extract the precious liquid went on as fast as the boats could bring it in. This was the oil which lubricated the engines and machines of the industrial revolution.

As well as blubber, a sperm whale has a huge organ in its head which helps to focus sound, enabling it to dive to locate and catch prey at huge depths. This organ is filled with up to 3 t of a mixture of fats and oils, which whalers originally mistook for the creature’s sperm. This could be partially separated to give a liquid which burned cleanly and brightly in oil lamps, and a solid which made candles far superior to tallow. The spermaceti candle became a lighting standard, from which the modern lumen is ultimately derived. These materials were also used in perfumes and cosmetics. This is in addition to the blubber which these huge animals provided. Clean lamp oil and candles enabled factories and offices to work longer.

As the US became industrialised, so households had more luxuries and whale oil lamps were greatly desired. Public buildings were lit by them. The whaling fleet and imports doubled and trebled. But there was a problem. For some reason there did not seem to be as many whales as there had been, and prices rose accordingly. 1846 was peak sperm oil year, then supply dropped as demand rose.

Alternative sources of oil were seals, and sealions. In 1891 Joseph Hatch, New Zealand MP, having largely eliminated the seals where he had a licence, had the idea of getting oil from penguins instead. Rather than being hunted they were just herded into pens, clubbed, and loaded into huge steam heated digesters, 500–900 at a time, giving half a litre each. Eventually they digested 3,500 a day, with a further 500 being the fuel. From 1891 to 1919 he disposed of three million penguins until public outcry forced the Tasmanian government to suspend the practice.

The desperate situation caused some American entrepreneurs to consider that annoying black liquid that sometimes came out of the ground

The desperate situation caused some American entrepreneurs to consider that annoying black liquid that sometimes came out of the ground when you are drilling for water. Or just came out anyway, like it did at (what was naturally called) Oil Creek, Pennsylvania. Rock oil (petra oleum) had been used by the Chinese as fuel to evaporate brine, by the Greeks in warfare, and had been distilled by the Persians to make lamp oil. It had just not been worth bothering with when wood, coal and whale oil were so cheap.

They were helped by geologist Albert Gesner, who had experimented with extraction of substances from bitumen from Trinidad’s Pitch Lake. Eventually he discovered that he could distil a clean liquid in good amounts from oil shale, and set up the North American Kerosene Company, by 1859 producing 5,000 gallons/day of lamp oil, and numerous competitors followed.

Gesner’s 1854 patent was challenged by Scottish chemist James Young, known as “Paraffin Young”, who had the first commercial oil refinery in Glasgow in 1851 (producing lubricating oil, solvent naphtha and lamp oil) also from oil shale. He had taken the precaution of patenting in the US in 1852, so won, and received royalties thereafter.

Young’s “paraffine oil” was chemically similar to German paraffin wax – that comes from Latin. Gesner called it “kerocene” from the Greek word for wax – the same idea. The British had paraffin lamps, the Americans kerosene ones.

Victorian paraffin lamp

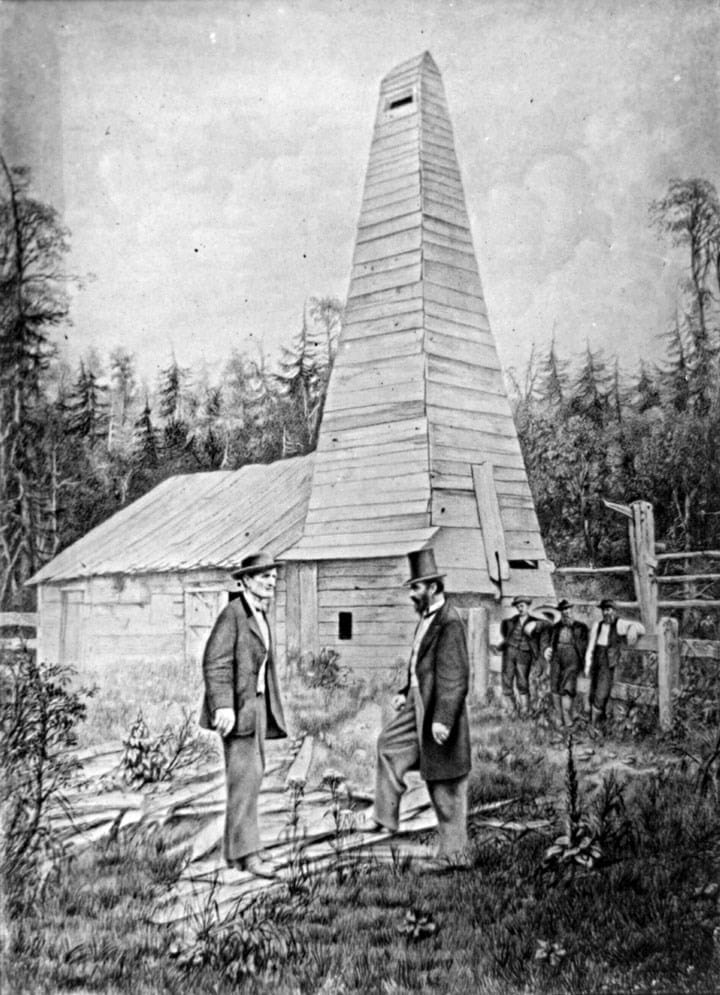

However, the discovery of oil by itself (if you drilled in the right area) changed the industry and the world. The shale oil industry lasted barely ten years, before the petroleum industry took over, making not just lamp oil, but also lubricating oil in large amounts. Famously the first commercial source was the Drake well (sited near Oil Creek), which reached oil in 1859, producing 2 m3/d but was overtaken by others and abandoned in 1861.

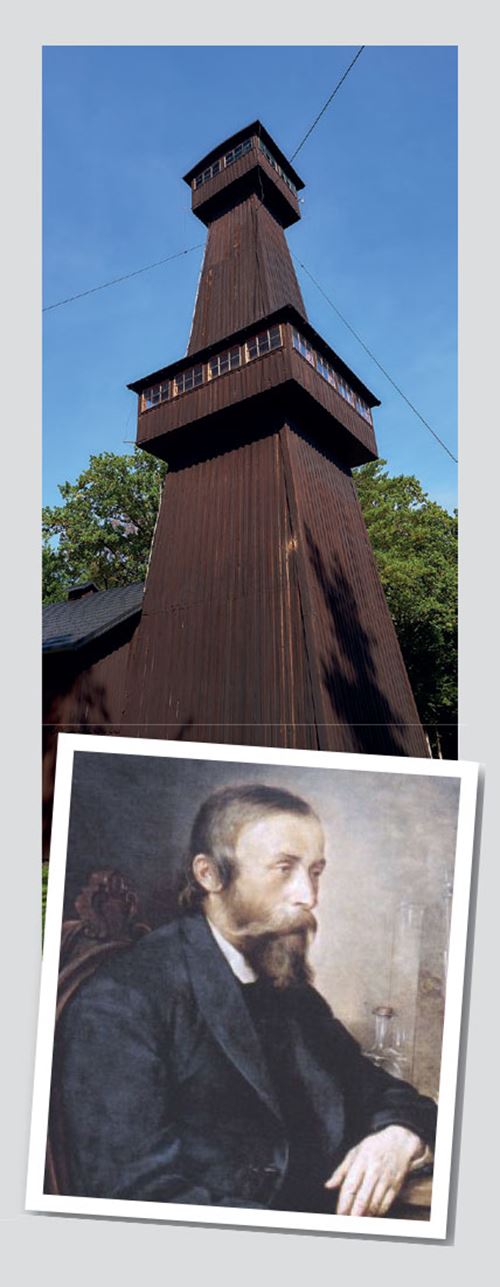

The oldest “oil mine” in the world is in Poland at Bóbrka, and opened in 1854. Ignacy Łukasiewicz, an entrepreneurial Polish chemist who was responsible for its operations, said: “This liquid is the future wealth of the country, it’s the wellbeing and prosperity of its inhabitants, it’s a new source of income for the poor, and a new branch of industry which shall bear plentiful fruit.”

It is home to the Ignacy Łukasiewicz Museum of Oil and Gas Industry, but is also still producing. Łukasiewicz actually set up a kerosene street lamp and opened an oil distillery in 1856. Though it produced kerosene, there was little demand, so it mainly sold lubricating oil and tar.

(Top to bottom) Bóbrka mine, now the Museum of Oil and Gas Industry, and founder Ignacy Łukasiewicz

Similar things were happening in other countries, but the US is notable for the speed and the extent of exploitation by hundreds of entrepreneurs inventing the technology and the market as they went along. In 1871 Standard Oil was founded by sharp businessman John D Rockefeller and became an unprecedentedly huge and profitable business. Known as “S.O”, it became Esso and later Exxon.

Coal had been dry distilled for 20 years before oil to get the tar and liquid components in horizontal tubes typically 4 m in diameter and 12 m long. This gives a greater surface area for vaporisation (and also for heating) than pots of equal dimensions. The materials coming off in turn were identified by density. The same equipment was used for petroleum distillation in batch mode.

Eventually in the US the horizontal tube was replaced by the vertical one and the distillation column or tower appeared, now considered emblematic of the oil industry in particular, and chemical engineering in general, though they were generally batch until about 1920.

This was the column with reflux and a set of trays inside, an adaptation of a patent by Aeneas Coffey, which brought together several innovations for the alcoholic spirits industry. The development of good theory of distillation as well as the practical technology for scaleup were major US contributions to modern chemical engineering. They also took George Davis’ ideas and formalised them into unit operations.

In the early 19th century, Ireland was the world’s leading producer of whiskey, largely based on a copper version of the old alchemist’s alembic. Aeneas Coffey was a Customs and Excise Officer so inspected many. He retired in 1824 to run a distillery. Being interested in and aware of distillation technology including the Stein column still, he came up with improvements at his works, patenting it in 1830, getting it approved by Customs and Excise in 1832, and attempted to sell it to industry.

The Irish whiskey industry saw no need to change from its traditional ways, so he offered it to the Scots, then very much number 2 in the business. His design was steam heated, removing the danger of scorching and reducing downtime. It was more fuel efficient and gave a high alcohol concentration at a good rate per day. The canny Scots saw the economic advantages and adopted it, so that Scotch whisky overtook Irish whiskey. The English later used it for gin.

Coffey stills for whisky in the US were a model for early chemical engineers.

Careless operators of the old tube stills had sometimes overheated the late part of the run, causing molecules to break and lighter fractions to be produced. This was the basis for cracking by which oil producers were later able to adjust the portions produced to some extent.

Good theory of distillation as well as the practical technology for scaleup were major US contributions to modern chemical engineering

Kerosene was the premium product, lubricating oil the basic. Heavier oil could be used for fuel, and tar for roads, but the lighter fractions were largely waste. Gasoline was too volatile to be used in lamps so had little demand and was flared off.

This was the opportunity Henry Ford used with his Model T Ford. It was not just the relative cheapness of the car, but the fact that it ran on gasoline, a dirt-cheap fuel. (It had kerosene lamps.) Soon the motor industry and the oil industry were in synergy, and both eventually dominated the world.

In 1912 Winston Churchill (First Lord of the Admiralty of the UK) made the controversial decision that future British warships would be powered by oil, despite the fact that the UK had plenty of coal, and oil supplies were far away in the US or the Middle East. However, oil gave twice the energy of coal and much less smoke. It also required fewer stokers. The first was HMS Queen Elizabeth, the first of five dreadnought battleships, often used as a flagship, which served in both world wars.

Oil gave twice the energy of coal and much less smoke...the ships were faster, better armed and could be refuelled at sea, leading to naval success

As a result, the ships were faster, better armed and could be refuelled at sea, leading to naval success. Because of this decision, in 1913 the UK Government took a 51% stake in Anglo-Persian Oil (which in 1954 became BP, now one of the largest energy companies in the world), and after the war was the controlling power in Iran until its independence in 1932.

The Shell Trading Company (1909 logo pictured left) was set up in 1833 to serve the Victorian hobby of collecting shells and making objects decorated with them. The Dutch East Indies (Indonesia) was an important source, where Royal Dutch Petroleum was later developing an oilfield. Eventually they were asked to include kerosene in a shipment to Europe. This expanded until they became transporters of oil products and the two companies merged in 1907, adopting the shell symbol.

The defeat of the Ottoman Empire (which was allied with Germany) in 1918 meant that its possessions were effectively divided up by the winning side, and the new countries of Iraq and Palestine were created to suit Britain and France in particular. Oil supplies were a significant consideration. HMS Queen Elizabeth was thus a major turning point in world history.

Initially the UK imported oil products, but in 1921 an oil refinery was set up at Fawley to deal with crude oil, just in time for this important aspect of chemical engineering to be of great interest to the new Institution of Chemical Engineers!

Sadly, the petroleum industry did not end whaling. In the 20th Century, better technology for finding, killing and processing these intelligent mammals in factory ships (whaling ship harpoon pictured above) reduced the costs of the products. One estimate was that the world whale population fell from 2.6 to 0.9m in this time, though it may be recovering.

Whale oil is not edible, but in 1907 it was hydrogenated for the first time in Germany to make a butter substitute, margarine, which became a staple through much of the century, especially in wartime.

Whale oil used in industry was called “train oil”. “Products from sea mammals” appeared on the ingredient labels of pet food in the UK until 1985, and on many cosmetics and some shampoos. In 2022 Japan, the notable reduction in demand for whale meat as human food means that stocks are being converted into pet food.

For more on IChemE’s Centenary, including historical reflections from IChemE members, visit the dedicated website: www.chemengevolution.org

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.