The Process Scaleup Journey Part 2: Using Modelling to De-risk Scaleup

CPI has helped over 1,000 businesses bridge the gap from beaker to bulk. In the second in the series, Kristi Potter explains why starting smaller can lead to smarter choices, lower costs and better control

Quick read

Going big can be a big risk: Scaling up by large factors (eg 100 L to 10,000 L reactors) carries significant risks, so scaleup decisions must be tailored to the process and product

Modelling reduces risk: Tools like Computational Fluid Dynamics (CFD) can predict how equipment will perform at larger scales, highlight issues such as poor mixing or dead zones and enable “scale-relevant” experiments at smaller scales before major CAPEX investments

Consider alternatives to scaleup: In some cases, physical and economic constraints make very large reactors inefficient; a scale-out strategy using multiple smaller units may offer a safer, more cost-effective route

WHEN scaling up, the instinct is often to jump in reactor volume by a factor of 10, 100 or even 1,000. However, the appropriate scaleup depends heavily on the industry and product type. For example, moving from a 100 L reactor to a 10,000 L system may seem like a logical next step – but it’s also a decision with major risks.

In the chemical industry, the jacketed stirred tank reactor (STR) is a common workhorse. Committing to purchase a 10,000 L STR – or even commissioning a demonstration run at a scaleup facility – represents a major investment. It’s essential to be confident that you’re selecting the right solution before making that commitment.

Your first instinct might be to revisit the principles taught during university – matching parameters like length-to-diameter ratio, agitator-to-tank diameter ratio, and impeller blade spacing. While these are useful starting points, relying solely on them for a major equipment purchase can be risky.

You might expect that by maintaining the same impeller tip speed and energy input, you would get a similar productivity or yield at both scales. Unfortunately, it’s never quite that simple in reality. You should always examine the likely performance of a geometrically scaled design to confirm it will perform as intended before placing any orders.

But how do you go about gaining the necessary confidence in that assumption before committing to putting your hard-earned funding down on a large CAPEX (capital expenditure) purchase?

De-risking CAPEX decisions using modelling

At CPI we help companies scale up their processes by examining these assumptions using modelling approaches to estimate how well the target-scale equipment will likely perform, and how that performance matches that of the current scale. We can also use these models to develop scale-relevant experiments using the current smaller-scale equipment, providing insight into whether the target scale is likely to be able to hit productivity targets before making final design decisions.

As a process engineer at CPI, one of the tools I use to evaluate scaleup potential is multiphysics modelling, including Computational Fluid Dynamics (CFD). This helps me assess the relative performance of different equipment scales for measures such as mixing times, heat and mass transfer rates, or another key performance criteria for the process. This helps highlight whether the current technology, in our example case the STRs, can provide the right physical conditions at scale for optimal productivity.

CFD can reveal conditions inside the equipment that are difficult, or even impossible, to measure directly with instruments. It uses numerical methods to simulate the movement and interactions of materials and energy in a system, creating and visualising profiles for your key process parameters throughout the vessel, allowing you to see the effects of flow, pressure, temperature and other operating conditions.

We also use CFD models to gain insight into parameters such as fluid flow patterns, temperature and concentration gradients, wall shear effects and areas where material can stagnate or where conditions are unfavourable for the reaction, so-called “dead zones”.

When applying CFD to scaleup, I first build baseline models to establish the performance metrics at the current scale, then apply the same physics to the proposed target-scale geometry. This lets me develop a strong understanding of the likely performance of a system at large scale, relative to the current operating scale.

This exercise can also be carried out in the opposite direction, from larger to smaller scale, to find operating parameters to mimic the performance of large-scale reactors in benchtop equipment. This enables lab- or pilot-scale experiments that more accurately reflect the performance limitations of large-scale operations – at a fraction of the cost – helping to de-risk decisions about scaling up.

CFD can reveal conditions inside the equipment that are difficult, or even impossible, to measure directly with instruments... creating and visualising profiles for your key process parameters

Modelling approaches to enable ‘scale-relevant’ runs

When scaling up equipment, ideally you would be able to run your process in equipment fully representative of the target scale before committing to the design or extending your facility to accommodate the new equipment. In some cases, you may be able to use a contract manufacturer to trial the process at the new scale before purchasing equipment. However, because their equipment is usually designed to handle a wide range of processes, it may not be optimised for yours, limiting how applicable the results are to your own setup.

You might be tempted to rely on standard rules of thumb to scale up your equipment instead of hiring kit from a contract manufacturer, assuming your process will behave the same in a larger, scaled version. Many companies have tried this with mixed success. To test how well these rules really work, here at CPI we can use CFD to predict performance at the target scale before committing.

When designing simulations to compare equipment performance, I begin by using metrics that are scalable across technologies – such as specific kinetic energy (J/kg) – to approximate the energy available for mixing or mass transfer. For instance, if a process relies on turbulence to ensure effective reactant mixing, matching the specific kinetic energy in the fluid can help achieve similar productivity in a scaled-up reactor.

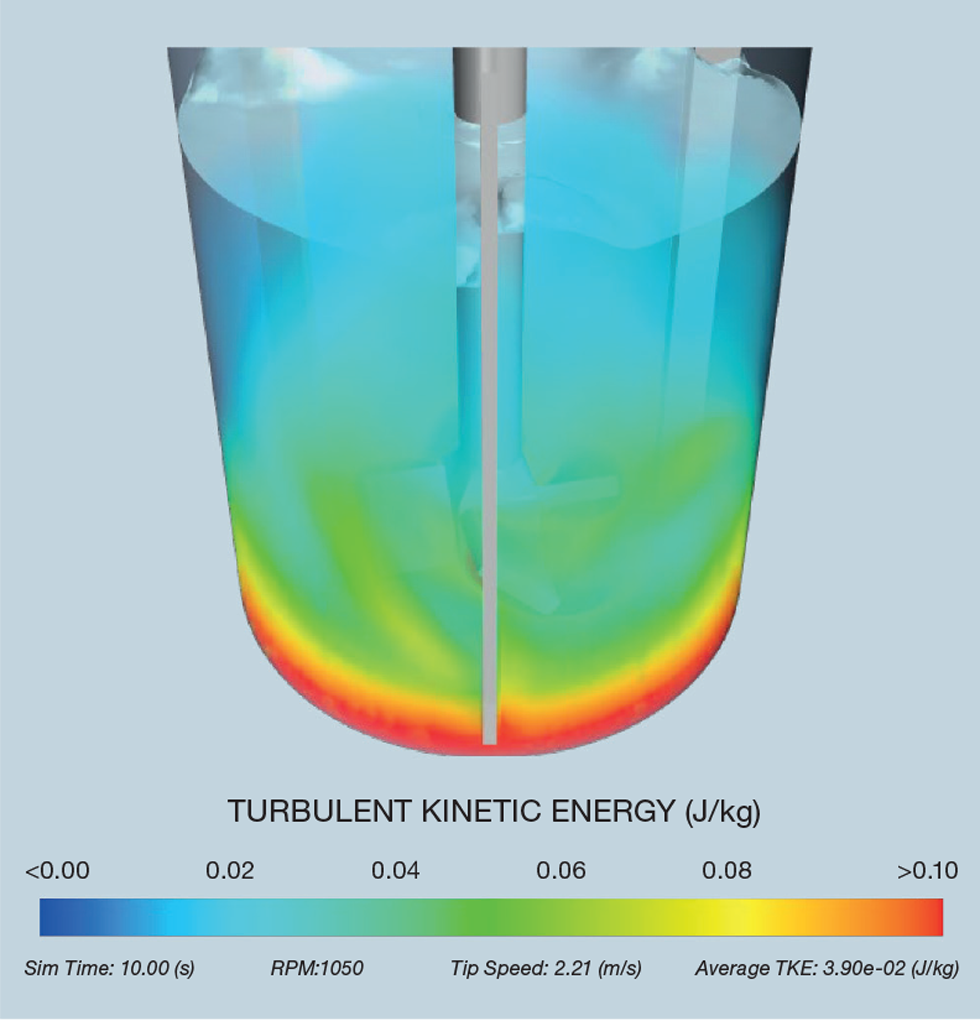

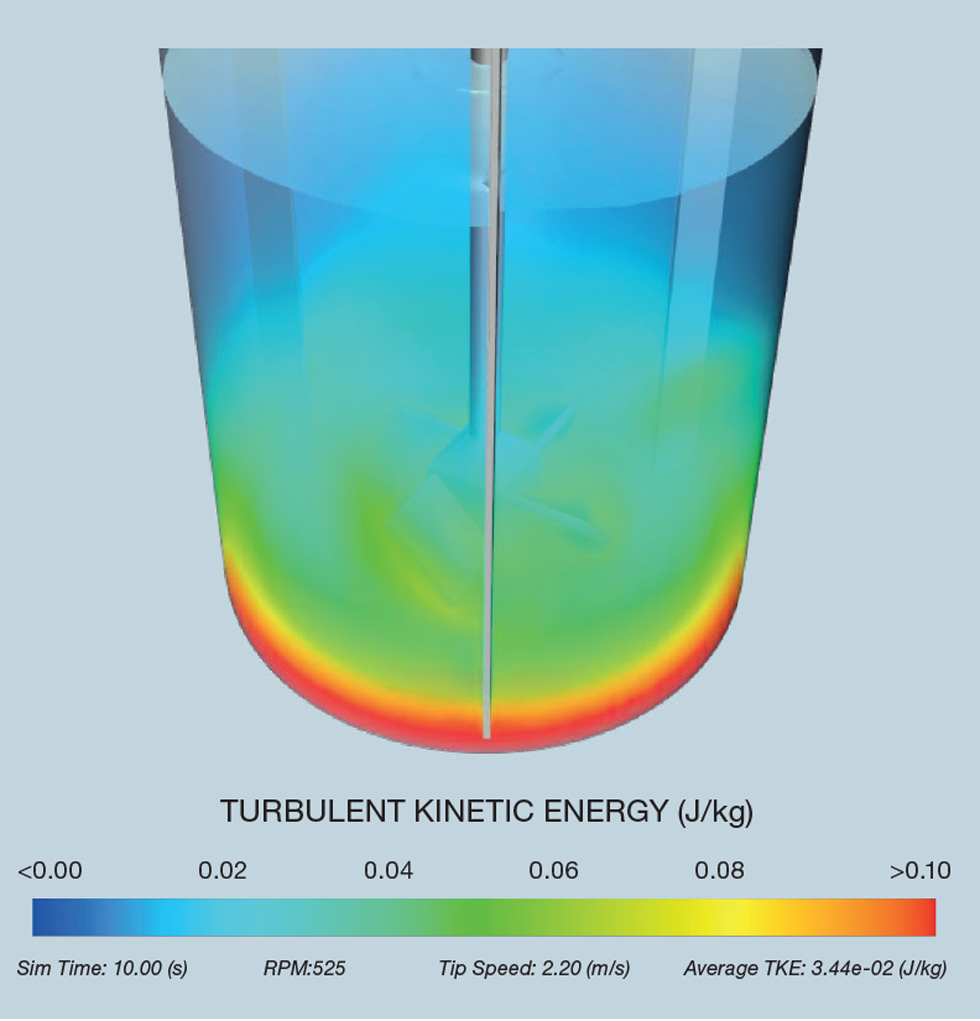

In the STR example I used the standard rule of thumb of matching impeller tip speed between scales in simulations of two STRs of 500 mL and 5 L volumes. In figures 1 and 2 you can see that in the geometrically similar models, the turbulent kinetic energy (TKE) profiles in the fluid appear relatively well matched between the scales at the same tip speed, with high levels near the agitator blades and lower values at the liquid surface.

However, when examining further, the volume average TKE of the liquid in the vessels is quite different, going from a value of 3.9 x10-2 J/kg in the 500 mL vessel to 3.4 x10-2 J/kg in the 5 L vessel, a reduction of 13% in the larger scale. If mixing or mass transfer is the limiting factor of your reaction, a reduction of this magnitude could have a detrimental effect, which could in turn impact productivity. This shows that while these rules may provide a reasonable starting point, they are not perfect.

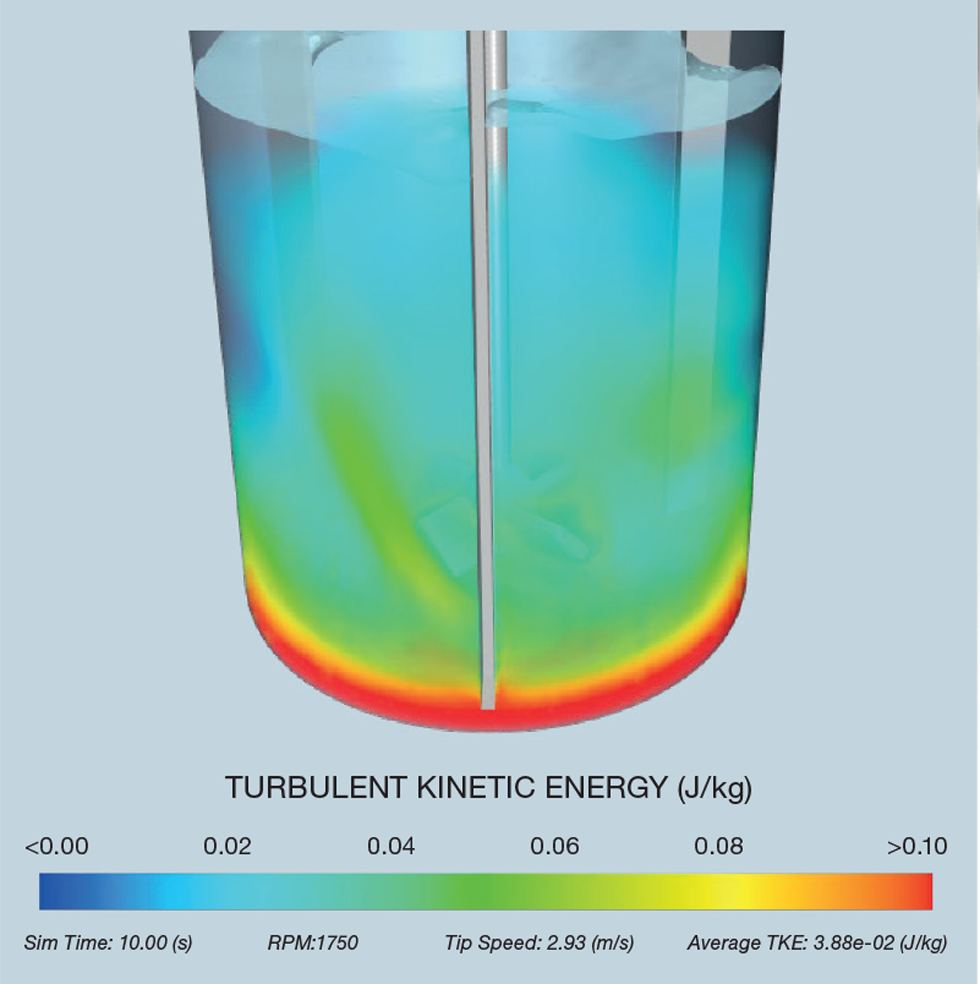

As a second example, we made a slight change to modify the 500 mL geometry away from the original, decreasing the impeller diameter from 40 mm to 32 mm so the two vessels are no longer perfectly geometrically scaled. It seems like a small shift, but now we can see in Figure 3 that the rule of thumb is no longer applicable. I had to increase the tip speed to 2.9 m/s to maintain the same volume average TKE as seen in the base 500 mL case from Figure 1.

Increasing the tip speed may not be a viable option to increase the energy in the system in some cases, as it could lead to shear effects that affect product quality or yield. If that’s the case, a redesign of the agitator by changing impeller type, number or spacing may be necessary to achieve the required performance at scale, all of which can also of course be explored using modelling.

These models show that even small geometry changes can significantly impact performance, and that there are limitations of the applicability of these general rules of thumb for scaling up. This is one reason why I like to use modelling – the valuable insight you can gain through using approaches such as CFD to, in effect, test different geometries before finalising design parameters for equipment scaleup.

Using CFD modelling, you can effectively run an in silico experiment at your target scale to compare the performance with the current scale instead of doing at-scale physical experiments. This approach can save time by avoiding delays in securing a production slot with a contract manufacturer, reduce raw material and consumables costs and support equipment design – improving your chances of success when scaling up.

Once I’ve identified the expected performance of the larger-scale equipment, I can then use the insights to design scale-relevant experiments using existing systems. By adjusting parameters such as agitation rates, heat transfer fluid flow, temperatures, and other operating conditions, it’s possible to simulate scale-related limitations and generate meaningful data on productivity and yield.

This approach can save time by avoiding delays in securing a production slot with a contract manufacturer, reduce raw material and consumables costs and support equipment design – improving your chances of success when scaling up

Predicting performance using modelling

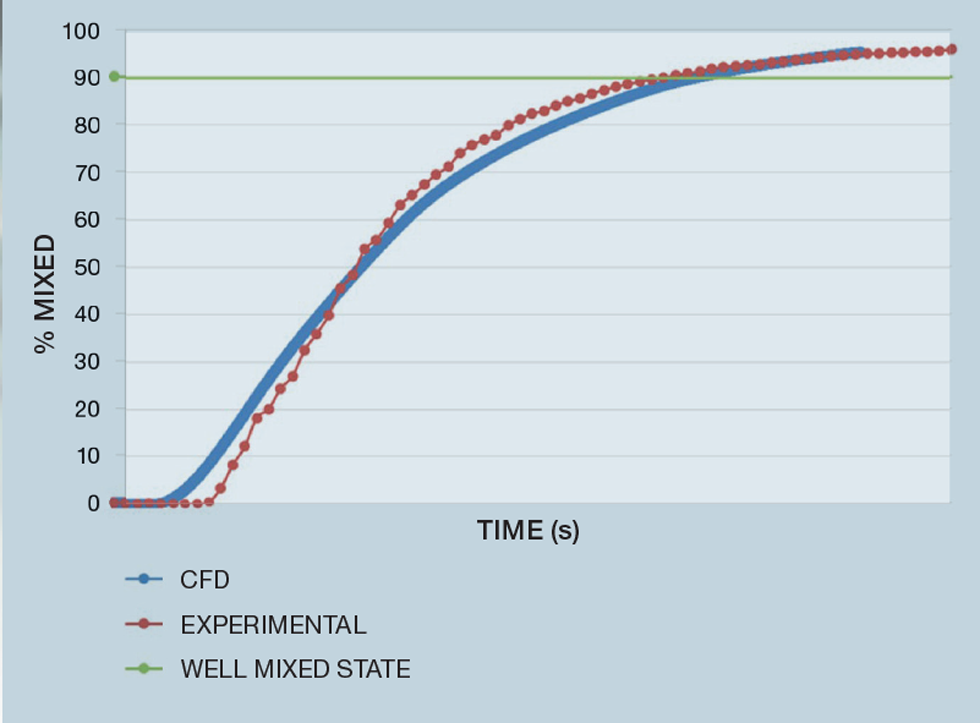

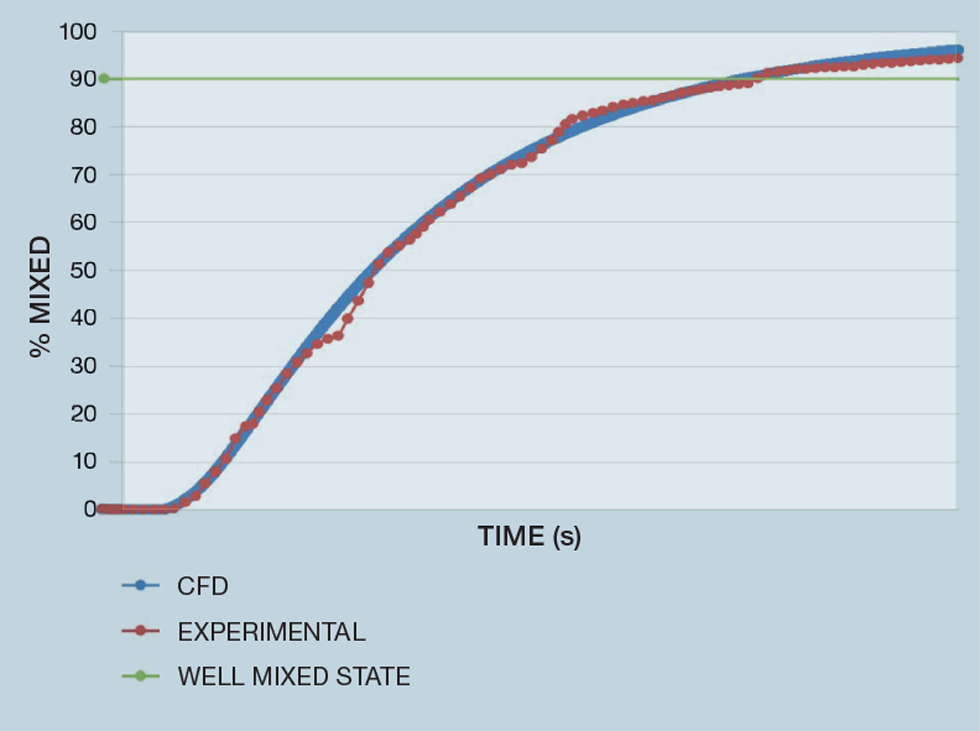

Figures 4 and 5 above show that CFD simulations can predict mixing times with good agreement to experimental data across scales. Once developed, these prediction models can be used to design in silico experiments to optimise operating parameters across scales, providing insights into the differences between equipment currently owned as well as for scaleup equipment design.

You can use these models to optimise process parameters in both your current scale and the target scale once the equipment is being commissioned. Rather than doing a number of trials to understand the dynamics of the system while commissioning, you can run a number of simulations first using different agitation rates, flow rates etc to find an optimum starting point for these parameters for physical trials, reducing the number of experimental runs needed and the associated costs and time requirements of these.

Scaleup vs scale out

When making the decision to scale up a process, there are a few things that should be considered apart from the equipment size. As previously stated, we need to make sure the equipment provides the right environment for the reaction to happen efficiently.

When considering things like heat transfer in our STR case, as vessel size increases it can become increasingly difficult to provide the required heating or cooling through jackets due to the surface area to volume ratio of the vessel reducing with scale. You can sometimes overcome these limitations by adjusting the temperature and flow rates of the heat transfer fluid. But at some point, it may require additional steps such as providing larger heat transfer area through internal coils or by providing an external heat transfer loop through a separate heat exchanger.

For mass transfer between phases, a similar problem can occur in STRs where to provide enough energy to the fluids for the targeted mass transfer rate, the size of agitator motor can become impractical in very large vessels. You may need to consider alternative reactor technologies to obtain the required energy input for optimised mass transfer.

These changes can have knock-on effects that require a redesign of your reactor system and of other unit operations, so it is important to consider the process as a whole when scaling up. Again, using modelling approaches can provide another level of insight into these issues before design decisions are final, mitigating some of the risks and the resulting impact on performance of the target-scale equipment upon commissioning.

In cases such as these, CAPEX and OPEX costs can increase to a point where the economics are less favourable using larger equipment or a different reactor type. This is when you may want to consider a scale-out approach instead, where you use multiple reactors of a smaller size to reach the capacity you need rather than using bigger equipment.

This highlights yet another aspect of the scaleup journey, the need to consider the economic picture. This will be the topic of the next article in this series, using techno-economic analysis and life cycle assessments to inform equipment choices from a sustainability and economics perspective.

If you have any questions about process scaleup or would like to discuss scaleup support in more detail, please get in touch at customerservice@uk-cpi.com or feel free to find me on LinkedIn

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.