The Future of Chemical Engineering in the Era of Generative AI

Jin Xuan and Thorin Daniel imagine a future when HAZOP sessions take hours not months, P&IDs are drawn automatically, and presentations write themselves

AI PROMISES to revolutionise the way we work by automating labour-intensive tasks and allowing complex processes to be completed in a fraction of the time. Recently, ChatGPT provided a boost to pharmaceutical companies by interacting with other AI tools and providing a more user-friendly interface.1 This allowed ChatGPT to answer questions based on information provided by the other tools rather than making users spend time searching for the information themselves. By being integrated into the wider platform of AI tools, ChatGPT has been able to improve the value of the entire system.

Large language models (LLMs) have been used by students to solve chemical engineering problems such as turbine efficiency and reaction time.2 They were able to streamline the problem-solving process by generating and solving the intermediate steps needed for the end result. If these tools are taken from the classroom into industry, a whole new set of opportunities for chemical engineering design will open up. The necessity of coding ability in chemical engineering has been established for some time, but despite this many chemical engineers have limited coding ability.3 Generative AI can automate the creation of small functions and portions of programs by generating chunks of code. While much of the current criticism in this area is directed towards its debugging ability, it has been shown more than capable of writing small functions such as those needed to set up excel files.4,5

Limitations of using ChatGPT in chemical engineering

While AI is powerful, it is limited in several significant ways. Many implementations of generative AI are hampered by a lack of suitable data and an inability to accept different input data types. Recent attempts to design generative AI for P&ID automation have shown promise but are hindered by the need for improved comprehension of chemical engineering-specific terms and a lack of available P&IDs to learn from.6 If complex chemical engineering models are to be successfully developed, much more data is required which may prove difficult to obtain.

ChatGPT has been known to argue facts which are incorrect, particularly if a previous prompt has asserted them to be true – famous examples of this include generating made-up references to support an incorrect argument.7 While it is not currently the case with ChatGPT, LLMs have the potential to learn from their input prompts. That information could then be output into the answer of another query.8 For this reason, it is not advisable to reveal sensitive information when using AI chatbots. Particular care should be given if a company plans on integrating an LLM into systems which contain confidential information.

Looking ahead: combining generative AI with other AI models

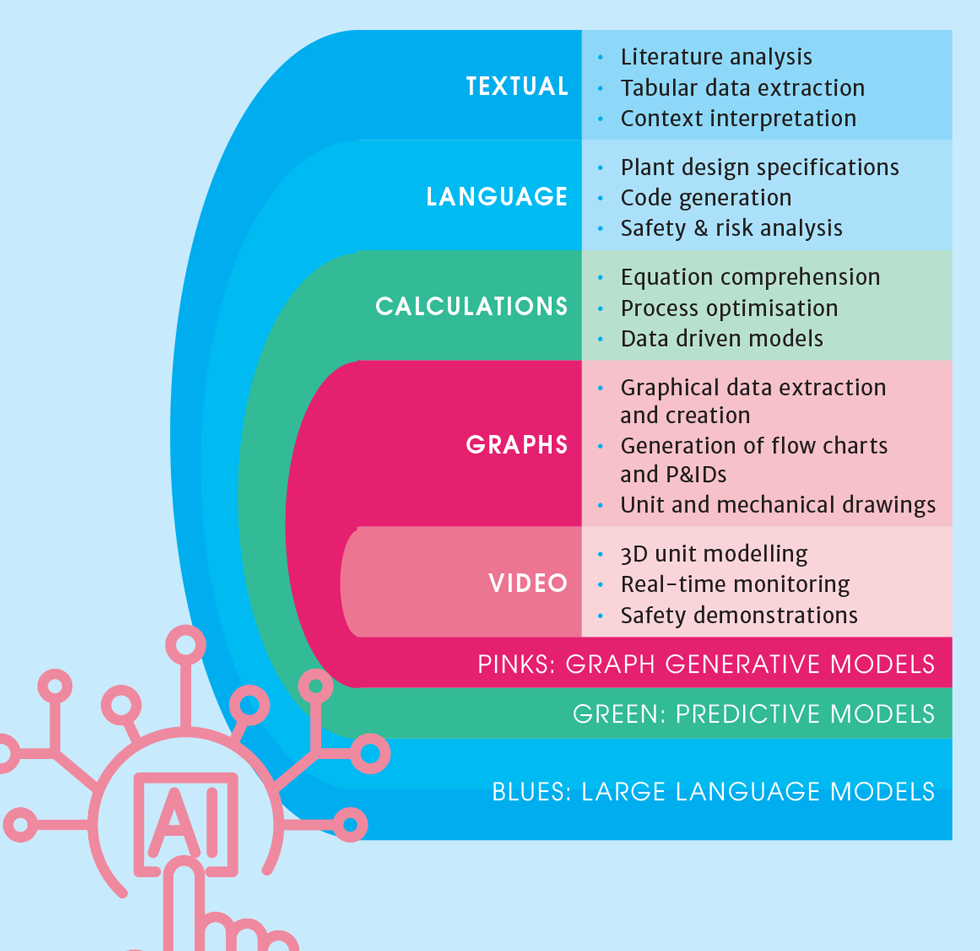

Chemical engineering tasks such as design and operation are complex and are typically composed of several steps. These steps may be tasks such as reading and writing technical reports, mathematical calculations, modelling, or generating graphical data to showcase economic performance. Each task relies on one or more types of information which, as summarised in Figure 1, would be parsed using a different form of generative AI models. These AI models are generally highly specialised and not able to work outside of the data which they were trained for, and so collaboration between several different types of AI is required.

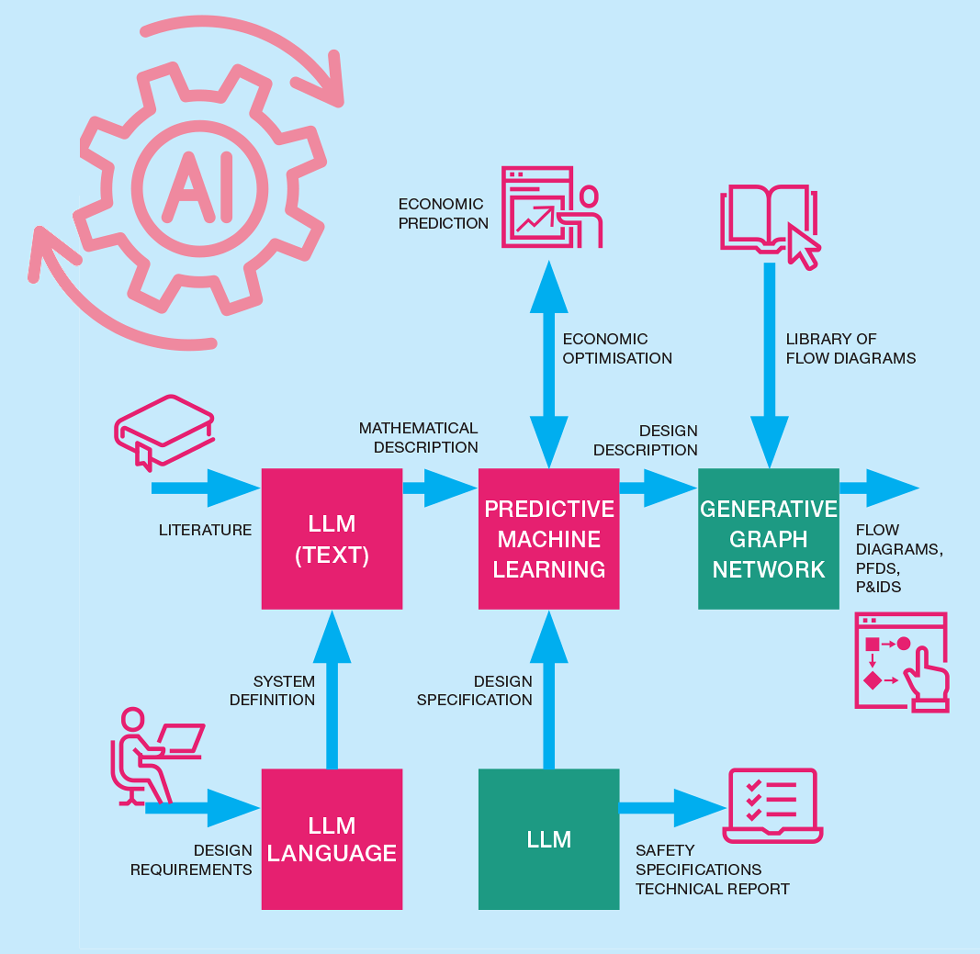

We envisage chemical engineers of the future using a suite of AI technologies to design a chemical plant in a fraction of the time it currently takes. Future AI will integrate several different kinds of models into one combined framework, able to parse information and generate results in one go. Each of the sub models will need to interact with one another seamlessly, either through tailoring the models to produce the exact information the next step requires or by creating bespoke joining models able to interpret and convert the data from one step to another. A design process may start with a lengthy literature review to determine the current state of the art and areas where new developments are likely to occur, followed by establishing the chemical process steps and units needed to complete them. Unit design would follow with flowchart and P&ID creation, before an economic analysis occurs. Each of these steps is highly time consuming and would require a team of engineers weeks or months to complete, and that’s before the lengthy and cyclical nature of safety analysis occurs. However, these steps could be condensed with the use of a set of AI models working in harmony as shown in Figure 2. In such a case, design requirements could be input to an LLM. This then creates a well-defined system definition to be passed on to a second LLM which gathers literature and data to determine important information about the current state of the art. The LLMs combined create a mathematical description of the problem which represent the complete system and process. Next, a predictive model could suggest how to cyclically optimise the economics before passing the now complete design specification to another LLM for the safety and technical reports. Finally, generative graph network could use the design specification and a library of flow diagrams to generate the require P&IDs and technical drawings. Collectively, end-to-end, full automation can be achieved.

While the use of AI may speed up the design process, the results will still need to be understood and the human aspect cannot be removed. If at any stage the AI generates a bad suggestion, understanding the reasons why will be crucial to prevent a poor design proceeding. So, these tools will not replace the skills of an engineer but allow them to work with greater efficiency and flexibility, with designs investigated in a day not months.

References

1. N Savage, Drug discovery companies are customizing ChatGPT: here’s how, Nature Biotechnology, May 2023, 41, pp585–586.

2. ML Tsai, CW Ong, and CL Chen, Exploring the use of large language models (LLMs) in chemical engineering education: Building core course problem models with Chat-GPT, Education for Chemical Engineers, Jul 2023, 44, pp71–95.

3. M Teles dos Santos, AS Vianna, and GAC Le Roux, Programming skills in the industry 4.0: are chemical engineering students able to face new problems?, Education for Chemical Engineers, Jan 2018, 22, pp69–76.

4. T de Kok, Generative LLMs and Textual Analysis in Accounting: (Chat)GPT as Research Assistant?, 2023. https://ssrn.com/abstract=4429658.

5. C Merow, JM Serra-Diaz, BJ Enquist, and AM Wilson, AI chatbots can boost scientific coding, Nature Ecology and Evolution, Apr 2023.

6. E Hirtreiter, LS Balhorn, and AM Schweidtmann, Towards automatic generation of Piping and Instrumentation Diagrams (P&IDs) with Artificial Intelligence, Oct 2022, http://arxiv.org/abs/2211.05583.

7. https://www.washingtonpost.com/technology/2023/04/05/chatgpt-lies/

8. https://www.ncsc.gov.uk/blog-post/chatgpt-and-large-language-models-whats-the-risk

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.