The Economic Case for Hydrogen in Domestic Heating

Despite its thermodynamic disadvantages, global energy technology specialist Thomas Brewer believes hydrogen has an economic and efficient role in domestic heating. It forced him to deviate from his usual mantra of ‘efficiency above all else’ to get there, though

The work of decarbonisation by chemical engineers is about how we can cost effectively enable our organisations’ transition away from fossil fuels. This requires foresight. A decision chemical engineers make on a project with a 20-year lifespan will still be operational in 2045, when in most global locations, internal combustion engine (ICE) vehicles will probably be in the minority and grid electricity will be mostly renewable.

It is unsurprising, therefore, that chemical engineers are researching and debating the prospects of the future of energy availability from renewables, and the likely role and cost of hydrogen. There is much public noise surrounding the conversation about heat pumps vs hydrogen for domestic heating. I have noticed how few articles are written from an unbiased perspective, how very few reports talk about the whole solution, and authors avoid quantifying the financial impact of their proposed solution. I couldn’t find an unbiased study with any financial logic, so, I built a model to assess the options, for my own interests. I found the results so intriguing that I wanted to share them.

Why am I interested?

I have been working in the field of sustainability for 30 years. I have always been employed in large multinational companies, where my current role is proposing and implementing new technologies to enable increased energy efficiency and reduce emissions. Meanwhile, I keep my thoughts independent through my hobby of improving my personal footprint, teaching on the topic (which I find wonderful for getting critical feedback) and helping small organisations reduce their environmental impact. I have often been surprised by how polarised people are in their opinions, and how even technically minded individuals form an almost unchangeable viewpoint after reading the first four paragraphs of a single article. I have no investments in hydrogen, heat-pump, battery storage or related companies, I am interested in seeing decarbonisation happen for environmental and social reasons and I am technologically agnostic in my quest.

Why should we ask the question?

Norway’s homes are almost all equipped with heat pumps to heat them during cold winters. It is sensible to suggest that the UK should emulate Norway, installing heat pumps in all houses when their natural gas boiler needs replacing. However, Norway’s population is less than a tenth of the UK’s and it has a mountainous geography with a low population density which enables the grid electricity to be supplied almost completely by hydro-electric, an energy source which is reliable and consistent. The UK, in contrast, has a high population density, and an energy distribution network that is based predominantly on natural gas. Most domestic heating uses natural gas, and the UK’s electrical grid was not designed for such a significant increase in load. Hence a suggestion that we could use the existing gas grid to transport the energy required in the form of green hydrogen rather than needing to upgrade the electrical grid as much, is one worth considering.

Many people compare heat pumps to hydrogen boilers using seasonal averages. This is a sensible calculation for a hydro-electric-based grid. For that scenario, we would quickly conclude that heat pumps are about 4–5 times more efficient than hydrogen boilers, which explains why the Norwegians, with 90% hydro-electric power, have adopted heat pumps almost exclusively. As the UK’s renewable power supply will be based predominantly on wind, the inconsistent supply plays such a significant role that using seasonal averages to design the system is not valid; we always want warm houses in the winter, but electricity from wind is not always available. Heat pumps or the alternative, hydrogen boilers, would need to be sized to be capable of heating homes during the whole winter, even the periods with low wind generation. So, the system will need to allow for enough energy storage to provide for a low-wind scenario which could coincide with a cold spell when heat pumps are at their least efficient, and when more heat is required.

Efficient electrical energy storage is expensive, which has traditionally led renewable system designers to include curtailment as a part of their design. Curtailment involves oversizing the wind supply to be higher than the grid connection to reduce the need for as much energy storage, and deliberately wasting the occasional electrical excess. The system design becomes an economical balance between oversizing the renewable generation and paying for additional electrical storage. Within the UK grid in 2023, curtailment is a small factor. As electrification and wind power become more mainstream, the financial decision between investing in excess wind vs electrical storage will lead curtailment to become a more significant factor.

Approximations and assumptions for the concept

The model takes UK wind data and considers a solution for 95% of the heating systems of all UK homes that are currently using natural gas or fuel oil. This assumes, pragmatically, that 5% of the current homes will find a better alternative such as industrial waste heat district heating systems or passive design. Currently, about 79% of UK homes use natural gas heating; and 5% use fuel oil for heating. Thus this is a solution for a hypothetical 80% of the UK’s 24.9m homes, which comes out at 19.8m homes.

About 61% of UK homes are semi-detached, 24% are detached, and 15% are flats. The model assumes that home insulation is improved, so that these homes require a 10 kW, 18 kW and 7 kW heat pump or hydrogen boiler, respectively. During a cold spell where the UK average outside temperature is -1°C and the heat pump discharge temperature is at 61°C for hot water heating and 45°C for the space heating circuit, the model assumes a COP of 2.61 which includes an allowance for evaporator de-icing, and a legionella cycle. These heat pumps are arguably oversized and capable of heating the respective home from cold within an hour. Consequently, they would only need to run for about 60% of the time to meet reasonable comfort standards within these better insulated homes.

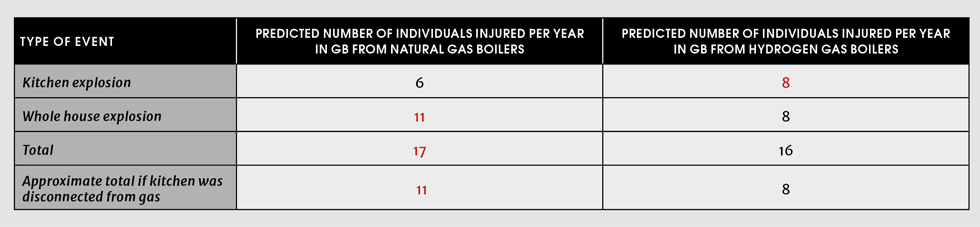

The model assumes that energy used from gas cooking is ignored. Chemical engineering consultant Tom Baxter discusses the risks associated with gas in the home, described in ARUP’s Hy4heat WP7 report which compares the risk of injury of natural gas leakage in the home with the risk of injury from hydrogen leakage. He suggests a new solution should look to reduce the risk of injury.

Figure 1 shows that the recommended standard of hydrogen gas installation if removing kitchen gas cooking would result in less injuries than the existing natural gas installation if cooking were converted to induction heating. Kitchen leaks are more likely than boiler leaks due to the number of valves and connections, regardless of the gas type. NOx emissions in the home because of naked flames in the kitchen are also of concern to the health of the occupants and hydrogen naked flames have a higher NOx emission than natural gas; another reason to eliminate naked flame cooking.

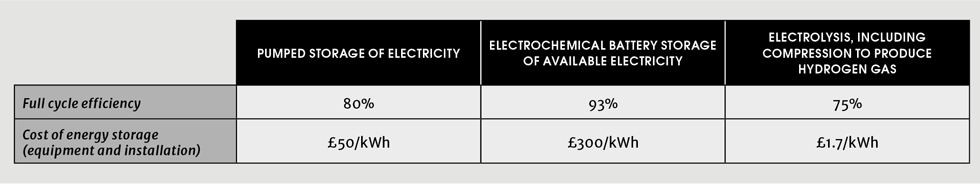

The pumped storage assumption is based on the SSE proposal for Coire Glas, a 30 GWh £1.5bn storage system in Scotland which will more than double the UK’s current pumped storage capacity. The capital cost of this pumped storage system is about £50/kWh which will be delivered at about 80% efficiency. Pumped storage is a good balance between low cost and high efficiency. However, it requires natural resources. The Mott MacDonald report, Storage cost and technical assumptions for BEIS (Department for Business, Energy and Industrial Strategy) suggests the equivalent of four Coire Glas-scale installations in the UK by 2050. The model optimistically assumes that ten more similar additional Coire Glas-size pumped storage schemes could be installed.

A distributed battery assumption could be configured with multiple 10 kWh batteries which typically cost about £3,000 installed, near or in homes with a heat pump. This could be coupled with larger battery storage systems like the £30m Chapel Farm 99 MWh battery installation near Luton, commissioned in 2023. The small battery systems at each home are similar to the proposed virtual power plants using electric vehicle battery capacity to help balance the grid. Placing these batteries at locations with grid limitations could reduce the costs of upgrading the grid system. This is a more expensive energy storage scheme than pump storage and for the purposes of the model it is assumed that battery storage schemes are limitless. In both cases cited, the cost is £300/kWh. Battery efficiency varies significantly with temperature, and typically ranges from about 90% to 97%. As the system design needs to be focused on the coldest periods, the model is optimistically assuming 93% efficiency, which would require many of the batteries to be in a heated environment.

Alternatively, the electricity generated from wind energy could be used in the electrolysis of water to produce hydrogen. While the fully installed electrolysis equipment costs about £2,100/kW, hydrogen storage in specially built cylinders is relatively cheap at about £23/kWh. The model, however, assumes salt mine storage which the US DoE in their report, Grid Energy Storage Technology Cost, calculate at a total system cost for hydrogen of $2/kWh. Electrolysis is the least efficient energy storage option, with a conversion efficiency of 75%, including compression. The waste heat from this conversion loss is useful for industrial heating, or in a district heating system. This has been ignored for simplicity.

Hydrogen from storage could be converted back to electricity in a fuel cell, to use in a heat pump. This would be more efficient but require large-scale fuel cell infrastructure which makes it possible to be the more cost-effective option in some circumstances and not in others. This complexity has been left out of the model.

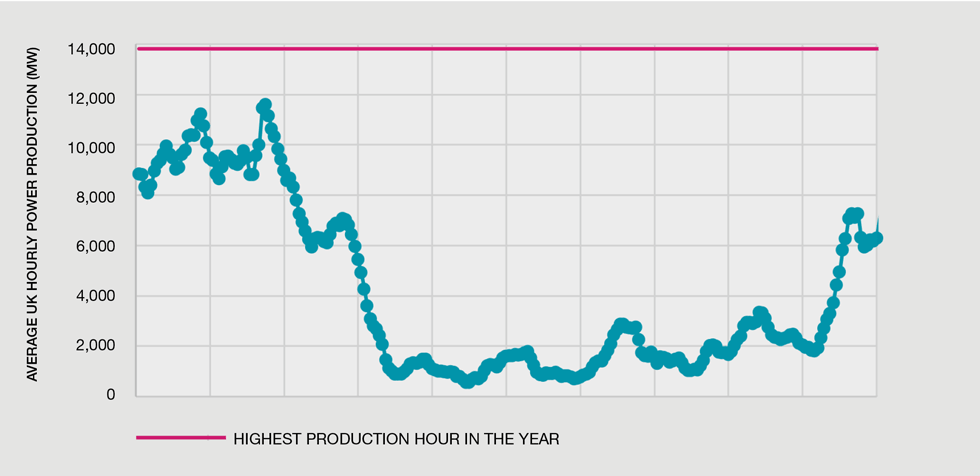

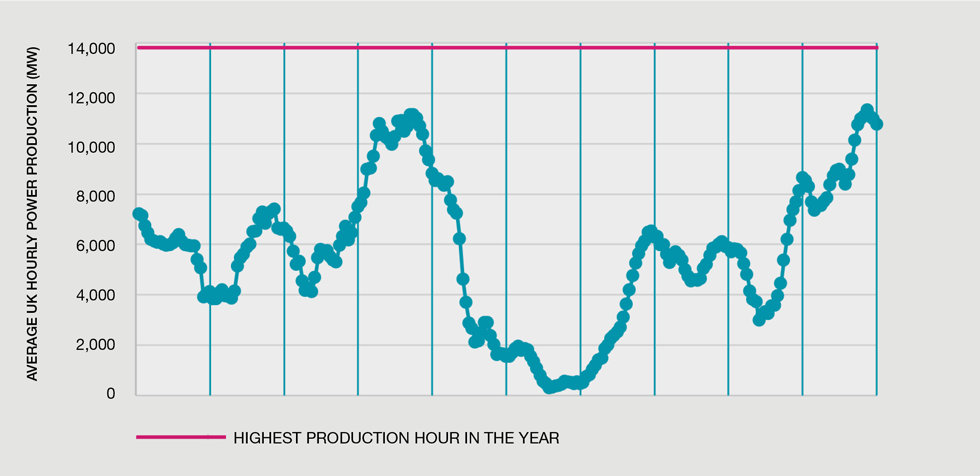

Wind generation in the UK

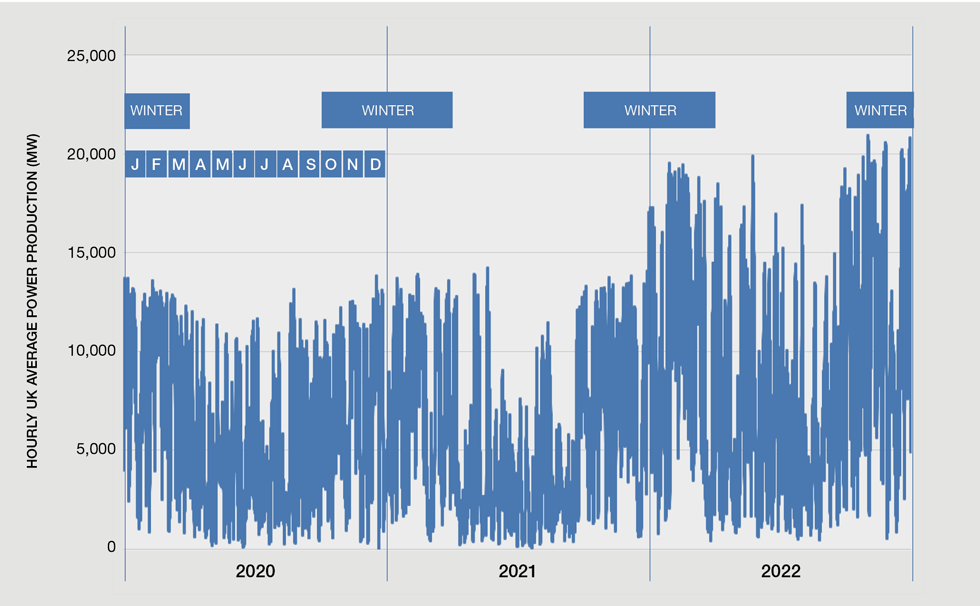

The UK government target for wind generation by 2030 is 50 GW. The UK offshore wind potential is reliable and available and has been estimated to be as high as 2,200 GW. There are, however, a few low wind periods that can last for several days.

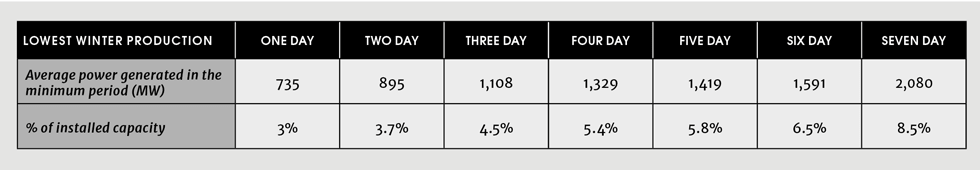

Using hourly wind generation data in 2020, it shows low wind generation during periods that could be very cold. The lowest-generating seven-day spell during a potentially cold period, was in April, with a similar one in November when the average wind generation yielded 8.5% of installed capacity. The least windy 24-hour period was on 6 December with a wind generation of 3% of installed capacity. This compares with 25.4% as an annual average, or 30.2% as an average during the winter months.

As the nation’s offshore wind farms build, there is likely to be some improvement in the worst-case values, as the probability of a windless high pressure sitting across all the wind farms at once reduces. As our nation is a small one, this risk remains.

Model generation outputs

Three options are compared:

- A total conversion of relevant homes from gas or fuel oil to using heat pumps

- A total conversion of relevant homes from gas or fuel oil to hydrogen boilers

- Combinations of the two

A system designed using average data over a period will differ from a system designed using a cold, still day. For a cold, still, short period of time, energy storage is financially favourable, whereas for a longer, still, cold period, it is financially more favourable to oversize the installed capacity of wind generation rather than invest in expensive energy storage infrastructure. The system will need to provide energy in all scenarios.

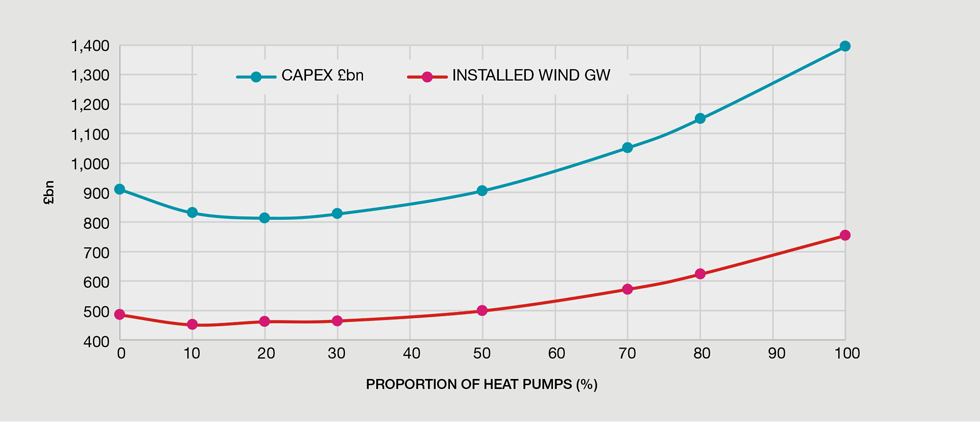

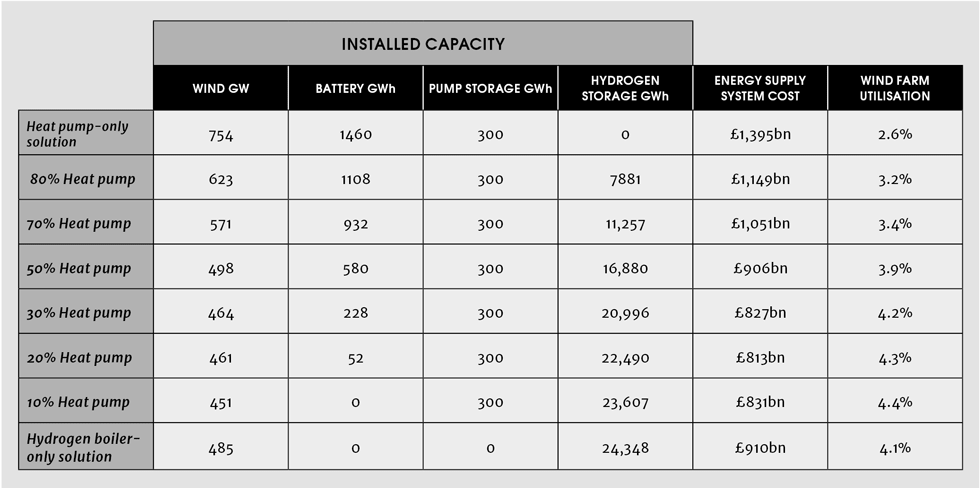

Taking these factors into account, the model can optimise for the lowest energy supply investment cost. This cost included electrical generation and energy storage. It doesn’t include electrical grid infrastructure, heat pumps, hydrogen pipework, or boilers.

This optimisation exercise was repeated for various ratios of heat pumps and hydrogen boiler solutions. It showed that a heat pump-only solution offers about two-thirds the efficiency of a hydrogen-only boiler solution, while proving 50% more expensive than a hydrogen-only solution.

Interestingly, the optimum ratio of the two technologies is relatively flat for the range 0%-50% heat pumps, demonstrating the value comes from the combination, not a specific combination.

Conducting a sensitivity analysis on the main assumptions gives some interesting insights:

- Efficiency of the energy storage systems has a small relative effect between technologies, predominately as all cost-optimised systems have significant excess electrical availability for most of the time

- The relative efficiencies of the heat pump and hydrogen boiler will directly affect the relative cost of the system performance. Improving the COP by 25% would reduce the difference in the cost of a heat pump-only solution by £100bn, to nearly £400bn more than the hydrogen boiler-only system. Simultaneously, a 10% improvement in hydrogen electrolyser efficiency would bring the difference back to where it was

- Hydrogen storage in pressurised vessels at £23/kWh would significantly increase the cost of the hydrogen business case, but still show a hydrogen-only system to be the more cost-effective and the best case as a combination of the two

- A reduction in installed battery system costs of £100/kWh would reduce the heat pump business system cost by 10%, with no change in the conclusions

- The inclusion of 25% solar power would reduce the overall cost of both systems, while maintaining a similar shape of the curve. While the solar generation in the winter months is low, the periods of poor wind typically coincide with periods of good solar gain for the seasonal average; this increases the generation yield in the poor generation weeks thus reducing the required amount of energy storage

- While the size of the heating load changes the absolute numbers it has no impact on the conclusions or the relative benefits of the technological choices. If, with further insulation, the heat load could be reduced, the overall investment cost required would reduce

Conclusions

This model was designed to answer a simple question: Is hydrogen for heat a sensible investment solution? It has answered with an unequivocable “Yes”.

The model has ignored the cost of the electric grid and gas pipe upgrading, which may add to the effective levelized cost. It has also ignored energy for transport and industry which limits the value of the study. However, considering the domestic heating system on its own results in a large amount of unused electricity, which artificially inflates the levelized cost of energy delivered. While this discussion is oversimplified, a few conclusions are clear.

A wind-based supply for heating will mean that large quantities of potentially unused electricity will be available for more than 90% of the year, for potentially very low cost. While this could appear wasteful, it provides further synergistical opportunities for the decarbonisation of other interruptible energy duties, such as production of hydrogen for road transport or supplying heat via heat pumps for interruptible industries.

The sensitivity analysis shows that these conclusions are robust even with significant variation in the assumptions on equipment cost, efficiency, and other electricity source options.

A cost-effective national heat pump-only solution is about £500bn (50%) more expensive than a hydrogen-only boiler solution. The most cost-effective system is a combination of the two, £100bn cheaper than the hydrogen-only solution, and £600bn cheaper than the heat pump-only solution.

A cost-effective national heat pump-only solution has a system efficiency 40% lower than the hydrogen-only solution, requiring more than 750 GW of installed wind capacity. A hydrogen boiler solution requires less than 500 GW but the most efficient system, however, is a combination of the two.

I have read many articles suggesting the UK government would be foolish to invest in hydrogen for heating. They deride it as inefficient, or not ready at scale. Other articles suggest hydrogen is an essential component in domestic heating as heat pumps are unworkable during periods of low wind, and the scale of the fuel cells to convert the hydrogen back to power in a short time is impractical. They say the UK government would be foolish not to invest in hydrogen infrastructure. Discovering that the optimum lay in a combination of both solutions was, for me, the highlight of running this calculation and sits well with my heartfelt beliefs in the value of synergy.

Reference

- Analysis and Comparison Study on Different HFC Refrigerants for Space Heating Air Source Heat Pump in Rural Residential Buildings of North China; Procedia Engineering 205:1201-1206

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.