Mind the Gap

Mo Zandi, Jarka Glassey and Brent Young discuss the emergence of Chemical Engineering Education 4.0

WE can all agree on the fact that engineering graduates have a strategic and long-term impact on quality and productivity growth in industry and service sectors. And in order to produce high quality products and services that are price competitive, we need a high number of qualified and highly-skilled engineering graduates that are well trained to respond to constantly changing needs. However, as academics, employers often tell us we need to prepare future graduates to adopt and integrate current and new skillsets such as digitalisation.

We designed two surveys for chemical engineering experts in industry and academia: the first to understand what skillsets are most important, and the second, to gather opinions on the level of knowledge and skills of current chemical engineering students and graduates. Many of the experts emphasised that digitalisation and computing skills are their primary concern for the future of chemical and process engineering, and require immediate attention.

The world has undergone three industrial revolutions, and the fourth – one known as Industry 4.0 – is now upon us. Industry 4.0 focuses on digital manufacturing and digitalisation of all sectors of industries and commerce. Climate change, Covid-19 and conflicts are currently the three biggest challenges for industry, and Industry 4.0 has the potential to drastically transform various industries and production techniques to meet these challenges.

It is founded on information and communication technologies – including initiatives such as the Industrial Internet, Factories of The Future, Internet of Things, Physical Internet, Internet of Services, and Cyber-Physical Systems – in order to achieve a high degree of flexibility in production; higher productivity through real-time monitoring and diagnosis; and a lower wastage of material in production, which contribute to the drive towards net zero carbon emissions. Manufacturers prioritise digital performance management, real-time supply chain optimisation, digital quality management, remote monitoring and control, predictive maintenance, and smart energy consumption. The changes these opportunities bring with them are the cause of significant changes in the job market and will change the portfolio of jobs available in the future.

Climate change, Covid-19 and conflicts are currently the three biggest challenges for industry, and Industry 4.0 has the potential to drastically transform various industries and production techniques to meet these challenges

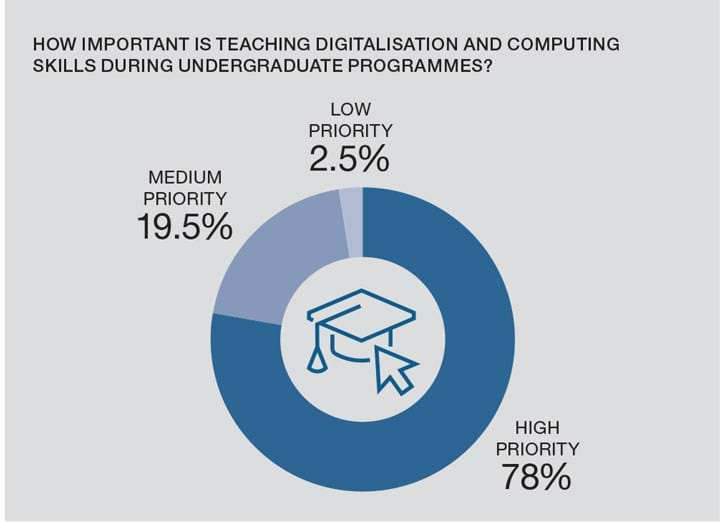

Engineers are the backbone of industrial development, and they need to pick up these new technologies more quickly than has been necessary in the past to accelerate needed digital transformation. However, our recent investigations show that it seems there is an inertia in the process industries to adopt Industry 4.0 technologies due to the shortage of digitalisation skills, and this has become a major concern for both industry and academics (see Figures 1 and 2). Currently, many practising engineers and academics teach themselves the required digital skills on the job, or digital projects are outsourced. This means that there are some serious lags before such technologies have the opportunity to proliferate, and therefore the lack of suitable digitalisation and computing skills to address current and impending challenges is hampering industry progress.

We asked

Our study, conducted online during February–July 2022, has been a global attempt to identify the digitalisation and computing skills gap from both academic and employer perspectives. In this study, two surveys were designed and deployed: one targeting academics and the other, industry. The surveys were circulated among chemical and biochemical engineering departments, chemical, pharma and consumer products industries, and the technology and manufacturing industries through the networks of IChemE, AIChE, EFCE, ESBES, and ASEE. We also approached Industry 4.0 experts, decision-makers and influencers directly. Over 110 responses were received from different countries, including the UK, EU, US, Canada, Brazil, Japan, South Korea, China, UAE, Malaysia, Singapore, New Zealand and Australia.

The participants were asked to identify and rate the core skills required for the future of chemical and process (including biochemical, formulated products and health care) engineering and manufacturing. The preliminary analysis showed that all the participants raised a red flag and expressed their concerns about the shortage of digitalisation and computing skills among recent graduates or in chemical engineering programmes (Figure 3). This is a piece of direct evidence that the skills gap is currently a global crisis facing all chemical engineering communities, and a reform is needed in our curriculum to help solve global challenges and trans-national issues such as the depletion of natural resources, climate change, decaying of infrastructure, supply chain security, natural disasters, and world conflicts.

However, although the majority of academics and industrialists agree that inclusion of digitalisation and computing skills in chemical engineering programmes is the highest priority, there is no unanimous consensus on what is the best or the most effective method to teach digitalisation technologies to undergraduate students. 49% of the academic participants believe that a combined approach of introducing the Industry 4.0 subjects through new modules and existing modules is required. Meanwhile 35% of the academic participants think embedding Industry 4.0 subjects in the existing modules will be sufficient and meet the industry needs (Figure 4).

David Bogle, IChemE’s new President, stated that: “We need to really develop systems thinking and use technology to support this. There is a bit of a danger in the digital space of focusing too much on the technology rather than understanding. Technology changes fast, but systems thinking will last. From what I have seen, there is lots of plug-and-play around the country without necessarily building a deep understanding of systems thinking to underpin this. And we need to be able to work with others, particularly computer scientists/engineers, who will have better knowledge of digital technology developments at the higher Bloom’s taxonomy levels. One area we do need to strengthen is statistics so that we really can understand the issues with effectively handling large uncertain, ever-changing data streams.”

Hence changes in chemical engineering education are inevitable, without which there will be no trained engineers to transform the industries to embrace all 4th Industrial Revolution benefits. Changes in chemical engineering education are neither a new thing nor a new debate for the entire chemical engineering community. In fact, the chemical engineering curriculum has been transformed through three main paradigms: unit operations, transport phenomena and product engineering. Are we now on the edge of entering a fourth paradigm in chemical engineering education?

IChemE’s Digitalisation Technical Advisory Group and the Education Special Interest Group are developing examples of modules with appropriate learning outcomes for dissemination through the IChemE Knowledge Hub, EdSIG Newsletter, and TCE – and also meeting quarterly with the Learned Society and the Education & Accreditation Forum to discuss next steps. Watch this space for further detailed analysis and proposals for curriculum development to address the gaps identified.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.