History of Nuclear Engineering Part 2: Building the Bomb

The story of the Manhattan Project and the race to build nuclear weapons is usually told about physicists but Martin Pitt says their achievements wouldn’t have been possible without chemical engineers and chemical engineering companies

IN AUGUST 1941, the results of the UK project to build an atom bomb, codenamed Tube Alloys, were handed over to the US with a promise that all results would be shared in a joint effort eventually called the Manhattan Project.

In April 1942, lead chemical engineer Henry Farr (1877–1958) and his younger colleague John Ruhoff (1908–?) at Mallinckrodt Chemical Works in St Louis, US were approached by chemist Frank Spedding (1902–1984). The US needed many tons of uranium at a higher purity than had ever been achieved commercially on the gram scale. The first stage was to deliver 60 t of pure uranium oxide from ore which was immediately available. The partnership made sense. Spedding had succeeded in the laboratory with an ether extraction, while as a pharmaceutical supplier, Mallinckrodt used ether on a large scale.

The process involved dissolving the crude material in nitric acid, filtering and crystallising to solid uranyl nitrate, which was then dissolved in ether, water-washed and extracted into aqueous nitric acid. This was then decomposed by heat to uranium trioxide, which was reduced to the dioxide. A heroic effort was required, pausing some processes, repurposing equipment, and building others, under a wartime shortage of materials and equipment. Fifty days after the first visit, an army representative called with the procurement contract which had now been signed by the government and was told that the final batch had been delivered the day before. A slight hiccup occurred when Ruhoff, an officer in the reserve corps, was called up to the army. However, he was assigned to return to Mallinckrodt, where he served the rest of the war.

Some of the material was converted into uranium metal in Ames College, Iowa by conversion to uranium tetrafluoride, then reduction with calcium, the heat of the reaction giving pure liquid metal with a slag on the top which was machined off when cold. Scaleup by Mallinckrodt allowed the production of 1,000 t of pure metal during the Manhattan Project, the necessary first step.

Neptunium and Plutonium

Natural uranium is mostly the U-238 isotope with 0.7% U-235 which is fissile – that is, it can be decomposed by absorbing a neutron, producing two or three in a chain reaction, unlike U-238. It was found in 1940 that bombardment of U-238 with deuterons (nuclei of deuterium or heavy hydrogen) in a cyclotron could create the next two elements in the periodic table, which were named neptunium and plutonium. First Np-239 is created, which decays to Pu-239. It was later discovered that Pu-239 could be produced in small amounts by neutron bombardment of U-238 in a reactor. As Pu-239 is even more fissile than U-235, it could potentially explode with a smaller critical mass.

On 2 December 1942, a nuclear pile containing 40 t of uranium oxide and 6 t of metal in graphite blocks housed in a squash court at the University of Chicago achieved a self-sustaining reaction with the production of heat and radiation. It produced just half a watt of power but it was enough to prove the principle.

Because of the urgency to beat Germany, it was decided to proceed with attempts to build uranium and plutonium bombs in parallel. The physicists were convinced they could do all the necessary development and design, leaving engineers with the (simple!) task of construction.

The physicists were convinced they could do all the necessary development and design, leaving engineers with the (simple!) task of construction

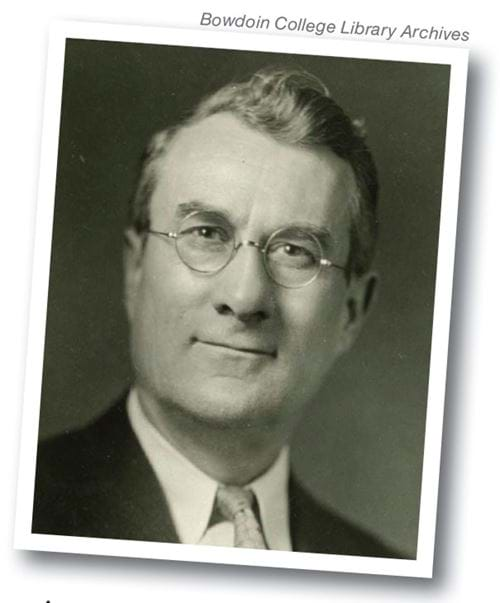

Fortunately, the Office for Scientific Research and Development (to which the Manhattan Project reported) asked MIT professor of chemical engineering Warren K Lewis (1882–1975) to chair a committee considering production, and Lewis (pictured) remained a key figure throughout. He was joined by Crawford Greenewalt (1902–1993), director of heavy chemicals at DuPont, Roger Williams (1890–1978) of its ammonia division, George Kistiakowsky (1900–1982), Harvard professor of physical chemistry and explosives expert, and a Chicago professor in both chemistry and physics, Robert Mulliken (1896–1986). Mulliken made poison gas for the US Army’s Chemical Warfare Service in World War One and later went on to receive a doctorate for the separation of isotopes of mercury by evaporation. They were later joined by Standard Oil’s highly regarded chemical engineer Eger Vaughan Murphree (1898–1962).

The Uranium bomb

Uranium was declared an essential defence material in the US, and production of ceramics and glass or other products containing it ceased. The US secretly bought up as much Belgian Congo ore as possible since it had uranium oxide content up to 65% compared with the typical 1% in US ores at this time. It was uranium from the Katanga mine in the Congo which fuelled the bombs dropped on Japan.

The higher the concentration of U-235 in U-238, the smaller the bomb could be. Being chemically identical, separation had to be physical. Murphree proceeded with pilot-scale gas centrifugation, but this was shelved in favour of two other methods: batch electromagnetic separation in a calutron or continuous gas diffusion. Two plants were set up on the same site, at Oak Ridge, Tennessee, with engineering services company Stone & Webster in charge of construction.

The calutron was a giant mass spectrometer built by electrical engineers Westinghouse, where gaseous uranium tetrachloride was ionised and deflected through a combination of electric and magnetic fields, with the different isotopes taking different arcs in giant tanks under a vacuum of 10-8 bar. Because copper was fully allocated for other war work, the US Treasury loaned 13,336 t of silver for the electromagnets. All but 0.036% was eventually returned by operating company Tennessee Eastman Corporation (TEC), now Kodak. Test runs were done with the physicists as operators and again with TEC staff whose nearly all-female workforce achieved greater production of a quite unfamiliar process.

MW Kellogg was given the task of developing a gas diffusion process under the leadership of MIT chemical engineering graduate and Kellogg vice-president Percival “Dobie” Keith (1900–1976). Union Carbide was the operating company. The process was based on a 20-stage plant run by ICI in Wales, using the more volatile uranium hexafluoride (UF6) as part of the Tube Alloys project.

Chemist turned physicist Philip H Abelson (1913–2004) had developed liquid thermal diffusion also using UF6 for isotope separation at the Naval Research Laboratory. With an estimated 18-month build-time and 600 days for its sequential 2,124 columns to come to pseudo-equilibrium at the final purity, it was discarded. However, in 1944, Lewis and Murphree learned of Abelson’s pilot plant and said it could be used in sequence with other plants, using the columns in parallel for enrichment to 1.4%. The chemical engineering contractor HK Ferguson (which had experience in chlorine plant, and thus highly corrosive conditions) built a full plant in four months, going on to operate it through a subsidiary, the Fercleve Corporation.

Eventually thermal diffusion fed the gaseous diffusion which fed the calutrons, providing 64 kg of 80% U-235 enriched uranium for the “Little Boy” bomb which was dropped on Hiroshima.

More chemistry

As well as operating the calutrons, TEC works manager Frederick R Conklin (1903–1967) was responsible for a complex chemical plant with a thousand staff processing streams in and out of the separation processes by reactions and vacuum distillation. Natural uranium was provided as uranium oxide (UO2) or uranium trioxide (UO3) which was reacted with carbon tetrachloride (CCl4) to give uranium tetrachloride (UCl4) and the deadly gas phosgene (COCl2). Enriched UCl4 was converted back to UO3, then UCl4 was remade to purify it. When the other separation processes came online their uranium hexafluoride (UF6) was converted to UO3 and then UCl4. The output streams were purified by the same process, enriched ones to the next stage, depleted ones as appropriate to earlier stages to maximise yield. Some 90% of the feed did not vaporise but was found as “gunk” around the equipment – UCl4 contaminated by radiation-initiated decomposition and interactions with carbon and metal parts. The calutron vessels were scraped and acid-cleaned every ten days, carbon parts burned, and the uranium recovered. The “waste” U-238 had to be accounted for in a high precision mass balance.

The UF6 process equipment had to be conditioned with fluorine gas to remove moisture and passivate surfaces, requiring a large amount of the gas to be produced and disposed of.

This was why chemical companies were needed.

The Plutonium bomb

DuPont was tasked with the production of plutonium, despite the cries of physicists that its expertise in nylon (stockings had been a sensation in 1940) was of no relevance. Its experience in hazardous materials and process development was, however, and it was also the only chemical company that built its own plant. DuPont had already lent some employees to the “metallurgical laboratory”, the code name for nuclear physics at the University of Chicago, including chemical engineer Charles M Cooper (1900–1971).

A 1 MW pilot reactor, the first continuous one, was built by DuPont engineers at Oak Ridge. The compromise saw physicists operate it and Eugene Wigner (1902–1995), a Hungarian Jew who had studied in Germany before emigrating to the US following the rise of Hitler, put in charge. He had studied chemical engineering at the Technical University of Berlin but moved into quantum mechanics and nuclear physics at the University of Princeton.

The reactor had aluminium-coated uranium cylinders inserted into graphite and was air-cooled. It provided much-needed reactor experience as well as enough plutonium for a separation process to be developed and subsequently built by Cooper.

This involved dissolving irradiated uranium in nitric acid, then adding bismuth nitrate and phosphoric acid. Bismuth phosphate precipitated along with plutonium phosphate. The precipitate was redissolved in nitric acid, oxidised and treated with phosphoric acid. Bismuth phosphate precipitated, but the hexavalent plutonium remained in solution, to be reduced and precipitated again.

For production, a site was developed on a desert area in a bend of the Columbia River in Washington State. Known as the Hanford Site, it was selected because of an abundant supply of cold Columbia River water needed to cool nuclear reactors, ample available hydroelectric power, mild climate, excellent transportation facilities, and distance from major population centres. In February 1944, DuPont began construction of B Reactor, the first full-scale nuclear reactor of 250 MW. It went critical in late September 1944, running at a higher level than any previous chain reaction. However, the power level dropped after three hours and fell continuously until it shut down the following evening. By the next morning the reaction began again, reaching the previous high levels before falling off. The problem was xenon-135, a neutron absorber with a short half-life, which had not seemed a problem to the physicists in the earlier reactor. Fortunately, DuPont’s reactor designer George Graves (dates unknown), known as “Old Marse Graves”, had built in a contingency of a substantial number of extra tubes, (despite the protests of the physicists and the army who had complained of excessive caution). These were filled and the reactor became stable when the extra neutrons overcame the loss to the transient Xe-135. Graves was widely regarded as the man who saved the project since there was no time to build new reactors.

The DuPont chemical processing plant was ready and, with the addition of two more reactors – Reactor D and Reactor F – enough plutonium was produced for the “Fat Man” bomb detonated over Nagasaki in August 1945.

Physicists vs chemical engineers

The physicists remained hostile to chemical engineers throughout the project, and even after it. A minor revolt in summer 1943 led several physicists to write to Eleanor Roosevelt and contact Bernard Baruch, a close friend of President Roosevelt, claiming DuPont was trying to undermine the project. Greenewalt later reflected: “To my way of thinking it was one of the greatest interdisciplinary efforts ever mounted…but the physicists always want to pull the covers way over to their side of the bed.”

Polonium

To trigger the bomb chain reaction at a precise time, a strong burst of neutrons was required. Either radium or polonium would cause this if in contact with beryllium, but polonium was 5,000 times as radioactive as radium. The final version would have polonium and beryllium separated by a nickel-gold barrier to stop its alpha emissions in a golf ball-sized trigger called an urchin. At the same time critical mass was formed, the urchin was smashed. There were two significant difficulties: polonium’s half-life of 138 days and the fact that no one had actually made a visible quantity.

Natural polonium is a product of a radioactive lead isotope, so Charles Allen Thomas (1900–1982), director of Monsanto’s Central Research Department, took on the task of trying to extract it from lead oxide found in residues from Canadian radium production. Thomas, who had turned down a role alongside Robert Oppenheimer at Los Alamos because it meant uprooting his family, started the research and development work in a warehouse near the company’s research facilities in Dayton, Ohio. Techniques of analysis and the new practical requirements of radiochemistry were required before any industrial process could be devised, using initial supplies of polonium from irradiating bismuth in the Oak Ridge reactor.

After a huge research effort, Thomas reported “the only known method was a long and laborious process, much as the Curies did. Accordingly, we began research to develop a process…with modern chemical engineering methods…I am happy to report that this has been accomplished.” In fact, both methods were successfully scaled up, the bismuth one using the production reactor at Hanford. He later noted that the role of the chemist and chemical engineer had been greatly underestimated in the Manhattan Project.

A former playhouse owned by Thomas’ wife’s family was obtained to do the processing, both of the lead oxide and irradiated bismuth from Hanford, each following intensive research of alternative methods.

To explain the presence of armed guards around the playhouse, a sign identified it as a film unit of the Army Signals Corps. While the owners were promised its return after the war, the building was so radioactive, it had to be demolished and transported to Tennessee for safe burial.

Lead oxide was dissolved in nitric acid (HNO3) and hydrogen peroxide (H2O2) to get the nitrate, other elements precipitated out with carbonate, clarified, and stored in large tanks from which polonium was removed every 60 days (called milking) by electroplating onto tiny pieces of nickel foil. In the other process, slugs of bismuth were irradiated for 100 days then sent to the playhouse to be dissolved in acid tanks. The near-saturated solution was repeatedly treated with bismuth powder, on which polonium deposited. Polonium was volatised from the powder, put into solution, and electroplated out. Because of its rapid decay rate, it was regularly sent to the weapon fabricators to be ready when the bombs were.

Radiation health protection was a new and developing discipline and one of the chemical engineers entrusted with developing and monitoring safe handling techniques was Lyle F Albright (1921–2010), later a professor at Purdue and author of major textbooks. He discovered polonium’s unfortunate ability to migrate onto and even through packaging when an empty packing case, used as a seat by a fellow safety officer, was dangerously active. As much as 20% of polonium was being lost in transit, so better containment and recycling of containers was introduced.

Radiation health protection was a new and developing discipline and chemical engineers (were) entrusted with developing and monitoring safe handling techniques

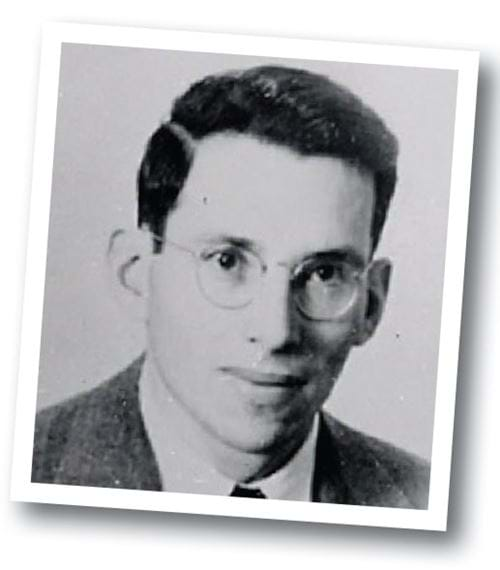

Another chemical engineer, health physics officer George Koval (1913–2006, pictured left), was at Oak Ridge and later Dayton. A Soviet spy, who had qualified at the Mendeleev Institute of Chemical Technology in Moscow, he was posthumously awarded the Hero of Russia medal by Vladimir Putin in 2007 for providing information that helped “speed up considerably the time it took for the Soviet Union to develop an atomic bomb of its own”. The Soviet bomb, RDS-1, was based on the Fat Man plutonium bomb.

In the next part, I will look at post-war development.

Martin Pitt CEng FIChemE is a regular contributor. Read other articles in his history series: https://www.thechemicalengineer.com/tags/chemicalengineering-history

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.