Francis Bacon – Future Fuel

Meet Francis ‘Tom’ Bacon, the father of the hydrogen fuel cell; Claudia Flavell-While writes

“WHEN there’s no more oil and gas” was the eye-catching headline of an article in the New Scientist, published almost 40 years ago in August 1972. It painted a picture of the future that was in many ways surprisingly accurate, suggesting that the world may hit ‘peak oil’ sometime between 1990 and 2010, and forecasting that one might plug the gap with synthetic fuels made from coal, oil sands and shale – temporarily at least.

But while the authors reckoned that such reserves might last us well into the 22nd century, rising living standards, particularly in the developing world, will sooner or later cause a gap between supply and demand that hydrocarbons cannot fill. “The only real synthetic substitute is likely to be hydrogen,” the article argues – and it’s only here that its remarkable predictive powers start to fail – “hydrogen produced from water using electricity generated by nuclear reactors.”

We might have to forgive them for failing to foresee the effects that accidents would have on the global appetite for nuclear power. Their suggestion that hydrogen would someday become a viable alternative to oil is still valid, with the latest forecasts predicting that by 2050 hydrogen fuel cells will fuel around a third of the world’s vehicles (see also p36).

The lead author of the article did have a good reason to predict a rosy future for the hydrogen fuel cell. After all, he dedicated practically his whole working life to its development: it was Francis Thomas ‘Tom’ Bacon, and it was he who developed the world’s first practical hydrogen fuel cell.

Discovered in a magazine

Bacon, born in 1904, died in 1992, is universally described as a “true gentleman” with an ancestry that could hardly be more distinguished – his forebears included the Renaissance philosopher and statesman Sir Francis Bacon. He attended Eton and Cambridge University, where he studied mechanical engineering; training that would stand him in good stead even though his career would take him deep into the field of chemical engineering and reactor design.

Having graduated, Bacon became an apprentice with CA Parsons, a producer of steam turbines. A few years into his job, he found himself intrigued by a couple of articles he read in the magazine Engineering, which – according to his Royal Society biography – described ideas for electrolysing water with off-peak electricity and using the resulting hydrogen and oxygen to power a vehicle. Bacon reportedly commented: “I was immediately struck by the potentialities of the thing, especially if it might be possible to make power electrochemically from the hydrogen and oxygen, rather than feed them to an engine.”

The idea of a fuel cell had already been around for a while, with the principle first demonstrated by the lawyer William Grove in 1839, but the theory had never been made practical. Bacon however was intrigued, and his engineering background and experience of working at high temperature and pressure would pay off.

He tried to convince his employers to back fuel cell research but was rebuffed because it was not relevant to the business.

Early experiments

Unperturbed by his employers’ lack of interest, Bacon proceeded to experiment at home. First experiments using a platinum gauze as catalyst quickly gave way to activated nickel electrodes separated by a pure asbestos cloth. The electrolyte was aqueous potassium hydroxide, operating at high pressures and over 100°C. He initially devised a reversible cell which would first split the water into hydrogen and oxygen and then in the same cell recombine the gases to produce electricity, though it was not long before he modified the design to a two-cell system where the electricity was generated in a separate chamber to the hydrogen production.

However while the experiments went well enough, the corrosive chemicals, high pressure and temperatures involved made them ill-suited to being carried out at home on the coffee table, so Bacon surreptitiously moved his equipment to his office at work. “He had made arrangements to be warned if the then managing director FGH Bedford was in the offing, and the contingency plan worked when the inevitable occurred,” records his biographer KR Williams. “Fortunately the apparatus had been shut down, Tom had escaped to a place of hiding and the managing director looked at the apparatus in a mystified way but fortunately asked no awkward questions.”

When the company did eventually find out, it gave Bacon an ultimatum: stop working on the fuel cell, or leave. Bacon, whose background left him comfortably well off, resigned.

On the move

In the following years, Bacon and his fuel cell work moved frequently across the country as varying support from companies and research backers took him from King’s College London to Fairlie in Scotland and eventually to his alma mater, the University of Cambridge. At Cambridge, the fuel cell project moved from department to department, from colloid science to metallurgy, and eventually to the Department of Chemical Engineering.

The legendary head of department John Davidson – at the time a young researcher – remembers Bacon’s enthusiasm, and his enthusiasm in how he spoke about the hydrogen economy. Clearly, Bacon was a man 50 years ahead of his time, perhaps even 100.

“He had old-fashioned charm,” Davidson says. “An Etonian who always wore an Etonian tie. When you first met him he would ask what you were interested in. If it had any relevance to his fuel cell he was deeply interested, otherwise he would switch off.”

Not that he was aloof, Davidson asserts: “He was very approachable. I never got involved with his project but we used to meet and talk.”

Davidson’s key memory of Bacon is his determination. Aside from the annual Etonian get-together, “he was in the lab every day of the year. I don’t think I’ve met anyone more single-minded.”

Slow improvements

Developing the fuel cell was an arduous task. With temperatures raised to 200°C and pressures of up to 600 psi, gaskets were prone to deteriorate and the asbestos diaphragm frequently failed. As Williams remarks, such reactors are to be treated with respect. “In later years Pratt & Whitney engineers were to claim with only a modicum of exaggeration that if a screwdriver were to be dropped into a vessel containing the hot electrolyte for a Bacon cell, it would dissolve before it hit the bottom!” But even with such powerful chemistry, Bacon’s target of 100 mA/cm2 at 0.8 V was proving to be elusive.

Part of the problem was establishing a stable interface between the hydrogen or oxygen and the electrolyte. At the suggestion of colloids professor Eric Rideal, Bacon developed a biporous membrane with relatively large pores on the gas side and much finer ones for the electrolyte, which solved the interface problem and made the fragile asbestos diaphragm obsolete.

The performance of the cells improved significantly. However their lifespan did not, as electrodes corroded and the nickel-plated cells buckled and collapsed.

The corrosion problem was finally overcome a few years later, while Bacon’s team was based at the chemical engineering department at Cambridge. The problem was that the oxide layer was breaking up as it was formed. One solution would be to pre-oxidise the electrode – much the same way as aluminium is anodised – but green nickel oxide is an insulator and therefore stopped the electrode from working. The solution in the end was to dope green nickel oxide with lithium to turn it into a black semiconductor, which resulted in electrodes that could quite happily withstand the conditions in the Bacon fuel cell without corroding.

A final problem of hydrogen catalyst poisoning was solved with the application of Teflon rings – and so a proud Tom Bacon presented a working six-cell fuel cell battery at an exhibition in London, producing 0.8 V per cell at 230 mA/cm2.

Though if he expected plaudits and interest from industry, Bacon was very much mistaken: the interest in his fuel cell was zero, and the Electrical Research Association, which had supported his work, withdrew funding.

Rescue arrived in the form of the National Research and Development Corporation, which funded the development of a 40-cell

6 kW battery operating at 60% efficiency, with a properly engineered water removal system and automated controls. The cell attracted considerable interest, but potential investors were put off by the need to provide cylinders full of oxygen and hydrogen.

Developing the fuel cell was an arduous task. With temperatures raised to 200°C and pressures of up to 600 psi, gaskets were prone to deteriorate and the asbestos diaphragm frequently failed

Take me to the moon

The moment of glory for these early fuel cells was to come courtesy of the space race, and the determination by the US to send people to the Moon. Pratt & Whitney, tasked with developing a practical source of electricity for the Apollo mission, licensed Bacon’s technology. “The Bacon cell was ideal,” writes Williams. “Hydrogen and oxygen were already present for propulsion and life support. Unlike heat engines whose efficiency falls with decreasing load, that of the fuel cell rises so it was possible by restricting electrical loading to operate at 75% thermal efficiency. Additionally, the by-product water could be used for drinking and humidifying the atmosphere of the space capsule.”

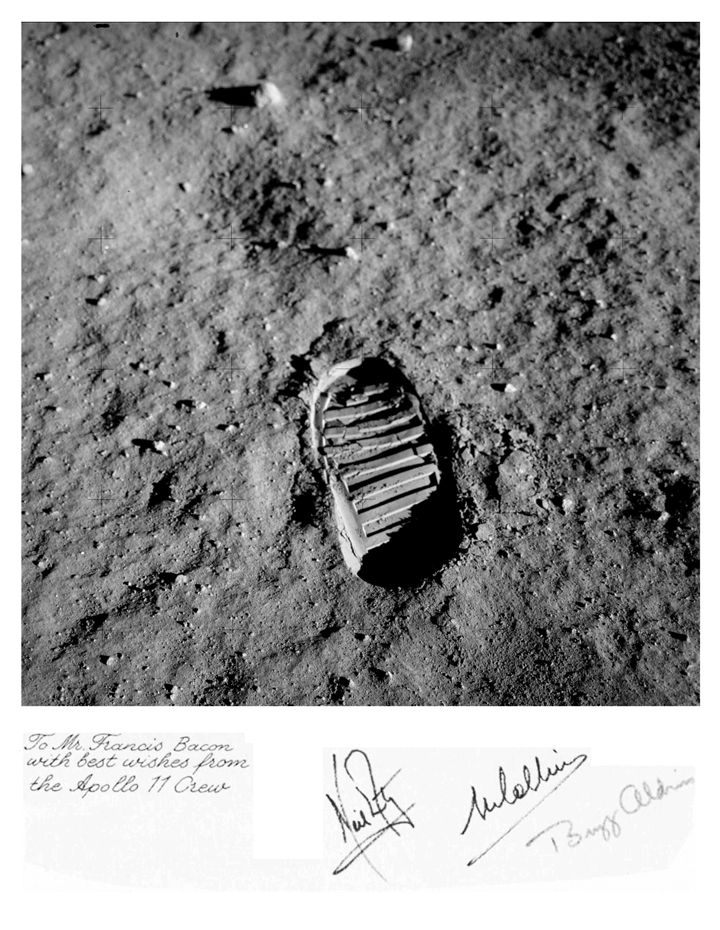

Suddenly, money was no longer a problem. Pratt & Whitney assembled a team of around 1,000 engineers and spent US$100m – a huge sum of money for the 1960s. The result was worth it: Apollo 11 made it to the moon, Neil Armstrong made his small step, and Bacon received a personal letter of thanks from Pratt & Whitney engineer Dick Foley: “The three power plants performed flawlessly and provided about 400 kWh of electrical energy during the mission. Your satisfaction must be very great that your pioneering efforts have made this possible and practicable.”

Not long after, Bacon and his wife were invited to 10 Downing Street to meet Armstrong and fellow astronauts Edwin ‘Buzz’ Aldrin and Michael Collins – and during a visit to the US he met the (then) president Richard Nixon who famously put his arm around him and said: “Without you, Tom, we wouldn’t have gotten to the moon.”

Numerous awards followed – but Bacon remained modest. His biography notes: “He would say ‘Well I had nothing to do with it, it was all up to the engineers at Pratt & Whitney.’ Yet without his dogged perseverance there would not have been a super-efficient fuel cell in the Apollo command and service module. As a result of the success of the Bacon design, Pratt & Whitney continues to supply the fuel cells, based on a somewhat modified design, for all the subsequent manned spaceflights and space shuttles.”

From moon to car?

Despite the glamour of going to the Moon, Bacon was an ardent supporter of the idea of using fuel cells for road transport. “Long before it was fashionable to be concerned for the environment, Tom had realised that its high efficiency and potentially low pollution made the fuel cell a highly desirable prime mover, and for the rest of his life he followed the development of fuel cells very closely, often being involved as a consultant,” Williams notes.

Indeed in his article for the New Scientist, Bacon writes: “The search for the ideal synthetic fuel would be a non-toxic fluid capable of being produced economically using the energy from a nuclear reactor and readily available materials, to which the fuel would revert on combustion,” and concludes that hydrogen would be ideal.

However he was well aware of the significant hurdles that would need to be overcome, from obtaining the energy to produce hydrogen, to designing a safe and efficient fuel tank, and the associated infrastructure.

In the aftermath of the Apollo mission there was huge enthusiasm for the idea, but ultimately the development task proved to be too big for the technologies available at the time. “The huge development effort at Pratt & Whitney on the Apollo cells had paid off because they perfected an existing piece of hardware for which little new science was required and almost any cost was acceptable,” Williams writes. “In contrast, when Energy Conversion Ltd started out there was no clear route to a commercially viable fuel cell. In such circumstances a large engineering effort lacking the necessary electrochemical background was doomed to failure.”

Even so, Bacon’s passion for fuel cells remained undaunted, and he continued to follow and support research efforts throughout his life. Though he died in 1992, a decade before the idea of fuel cell-powered vehicles regained some real momentum and traction, there is no doubt he would have been very pleased to see the efforts under way today to make such vehicles a mass market reality.

Originally published in June 2012

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.