Brewing Up a Storm: The Origins of Biotechnology Part 2

In this two-part contribution to his series about chemical engineering history, Martin Pitt focuses on the interesting developments in biotechnology

BIOTECHNOLOGY is as much an exciting part of chemical engineering today as it is promising for its future. In the second of this two-part article I continue to look at its long use, and how it suddenly changed the world. Here, I look closely at the atom bomb and the antibiotic.

In 1941, Britain was at war with Nazi Germany and sent two missions to the US (which had remained neutral). Both resulted in unprecedented co-operation between the two countries and amongst companies, rapidly advancing the production of totally new technologies which changed the world. One is well known, but I think the other is more important.

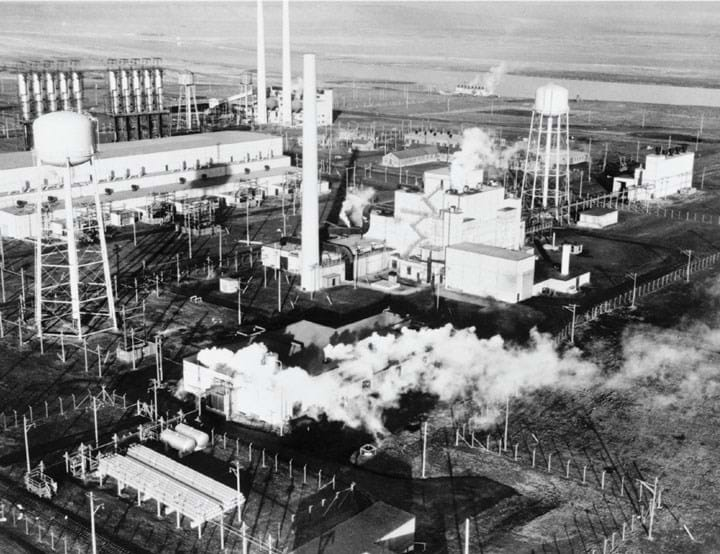

The first was in August, when Australian physicist Mark Oliphant (1901–2000) of Birmingham University revealed Britain’s atomic secrets, which were well ahead of the US. This resulted in UK work being combined with US work to produce the atom bomb in the then secret but now famous Manhattan Project.

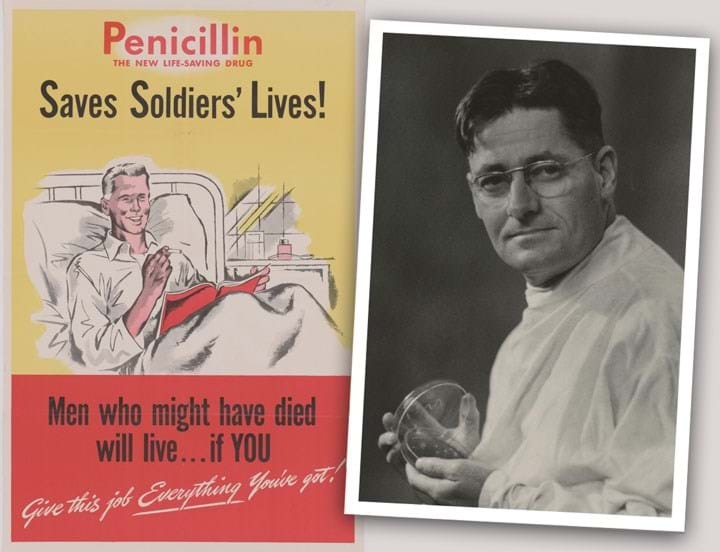

The second followed in November, when Australian pharmacologist Howard Florey (1898–1968) and British biochemist Norman Heatley (1911–2004), both from Oxford University, went to try and persuade US firms to produce penicillin on a larger scale than could be managed with British industry, which was already stretched and subject to German bombing. By June 1944, enough penicillin had been produced in order to support the Normandy landings on D-Day.

Ironically, one of the lives to be saved by this new wonder drug was Adolf Hitler (1889–1945)! An assassination attempt on 20 July 1944 with a bomb in a briefcase under a table caused multiple wounds to his legs with splinters of wood and fragments of leather, which went septic and made him gravely ill. His doctor provided penicillin which resulted in a rapid recovery and earned him the Iron Cross in return. The penicillin was probably captured from troops involved in the Normandy landings (6 June) and requisitioned when Hitler was injured. His doctor, I expect, was well aware of US publications writing about the wonder drug and demanded what had been found on captured or dead US troops.

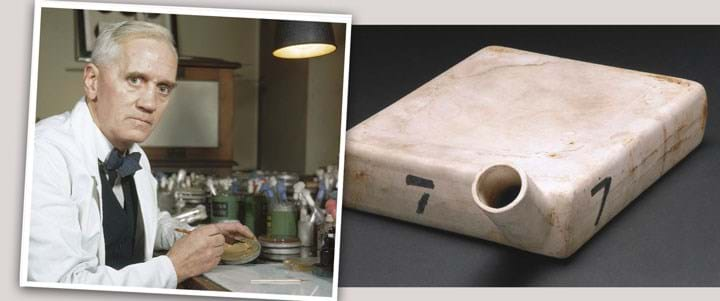

The beginning of penicillin

Alexander Fleming (1881–1955) was an expert on Staphylococcus, a common infection of wounds with no known treatment, and immediately realised the importance of his observation when a chance contamination (from a laboratory studying moulds on the floor below his) stopped growth of this bacteria on one of his cultures. Careful experiments showed that there was an unknown substance which was released by the mould. You did not need the living organism as others had supposed, so this substance might be used as medicine. Fleming also carried out experiments on mice to show it killed bacteria in the body without being toxic, and on human surface wounds to show it was not irritant.

The work was largely ignored, but he sent samples of his mould to anyone who expressed an interest while he and others continued with lab work, producing enough for successful topical treatment of boils and skin and eye infections in St Mary’s Hospital where he worked.

In 1939, Florey, Ernst Chain (1906–1979), and Heatley took up the challenge. The Medical Research Council offered only £25, so Florey went to the Rockefeller Foundation. It was Heatley who developed a method to determine the concentration of the active substance, said by Gladys L. Hobby, author of the major book on the subject, Penicillin – meeting the challenge (1985), to be “the most important contribution made by anyone to the ultimately successful development of the drug.”

He also designed the fermentation vessels, got them made in Staffordshire pottery (the glassworks were too busy), and devised a separation process where the filtered liquid was acidified, extracted into solvent, then extracted back into water at a higher pH, personally building a liquid-liquid multi-column contactor with controlled drop size. It was further purified and concentrated by vacuum freeze drying as the first systematic production process. Oxford professor Sir Henry Harris (1925–2014) said “without Heatley, no penicillin”. However, only Fleming, Florey, and Chain shared the Nobel Prize.

Penicillin in the US

The American companies all said penicillin was too risky for investment so Florey went home. However, Heatley stayed to work at Northern Regional Research Laboratories (NRRL) at Peoria with the director, microbiologist Andrew Moyer (1899–1959). They had an extensive collection of moulds and tried hundreds of varieties of Penicillium but only found one that had antibacterial action. Eventually a mould on a cantaloupe at the local market was the one which was adopted.

A by-product of corn milling in the US was corn steep liquor and uses for it were wanted, so NRRL always tried it with any culture they investigated, and in this case it worked very well. Substituting lactose instead of sucrose also helped. They increased the yield per volume 12 times.

Later, Heatley was puzzled and disappointed that Moyer published their work under his name only. Even later, it turned out he had patented it in the UK and US and he was inducted into the National Inventors’ Hall of Fame for this. Fleming felt that to patent penicillin would be unethical and Florey’s boss agreed, so UK companies had to get licences from the US.

The attack on Pearl Harbor on 7 December 1941 caused the US to join the Allies against Japan and Germany. In 1942, intelligence came that Japan and Germany were trying to develop biological weapons, so the government stepped in to find antidotes, taking over the project with a number of companies in collaboration. The opening of Uncle Sam’s wallet, and joint access to the research, led 18 companies to US production with versions of Heatley’s method with more containers and tweaks to the nutrient mix and extraction methods. Actually, this collaboration by a set of companies was illegal under US Anti-Trust law to promote competition, so it was suspended for penicillin, the only product ever.

This collaboration by a set of companies was illegal under US Anti-Trust law to promote competition, so it was suspended for penicillin, the only product ever

Florey had asked for enough to do proper clinical trials, but this never came. He remarked “after telling the Yanks every single thing we knew on the understanding that they would give us some penicillin to do some more cases… they have kept the lot for themselves!” Instead, the UK companies ICI and Kemball-Bishop developed plants, so Florey was able to carry out highly successful clinical trials showing the exceptional worth of penicillin as an antibiotic and antiseptic.

Glaxo was a food and dairy-related business but turned its expertise with blue cheese mould (Penicillium roqueforti) to the production of penicillin. They first grew the mould in horizontal milk bottles and supplied “mould juice” to Oxford in milk churns. With other companies, the UK had enough product to give to its forces. For the first limited supplies, Winston Churchill (1874–1965) took the decision, on practical rather than moral grounds, that it should be prioritised to treat venereal diseases. These were common among the armed forces, and prompt treatment meant that men could be returned to action much more quickly than the wounded could. By July 1943, British penicillin was sufficient for British forces in the Italian campaign for both causes of disease. Two years later, it was available for civilian use. Meanwhile, back in the US, NRRL had suggested that for really large-scale production the technique of submerged fermentation in an aeriated tank should be used.

Two companies had an advantage because they already had deep tank fermenters (see TCE 982, p34–7) – Commercial Solvents Corporation (CSC) for acetone and butanol and Pfizer for citric acid. CSC’s plant was designed by Margaret Hutchinson Rousseau (1910–2000), the first female member of the AIChE. You can read more about Pfizer’s effort in Pfizer’s Penicillin Pioneers by Jasper Kane and John McKeen (TCE 824, p54–5).

However, as important as the bioreactor was, so too was the separation and purification process. For that we have to thank the people known as The Mushroom Man and Dr Pod.

The Mushroom Man and Dr Pod

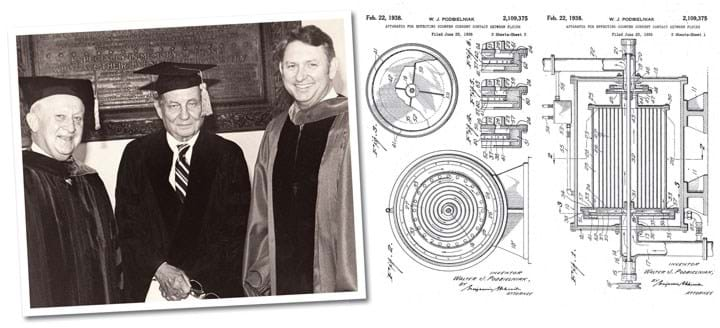

Ray Rettew (1903–1973), with his company Chester County Mushroom Laboratories, produced the majority of mushroom spawn in the US and volunteered to help with penicillin, but the organising committee initially refused and somewhat mocked him as “the Mushroom Man”. However, he had the technology and expertise in sterile operations and was finally accepted, quickly producing useful amounts, expanding with Wyeth laboratories for finishing operations to become the first and largest producer of the drug in the US while bigger companies were still coming to grips with the mould culture.

The other problem was the liquid-liquid extraction. Scaling up Heatley’s equipment would increase the residence time, giving excess hydrolysis. Rettew first used a mixer and a centrifugal separator sold for separating cream from milk. Variations on this were adopted by other companies. However, he eventually hit upon a centrifugal contactor which did both jobs, invented in 1934 by the son of Polish immigrants to the US, Walter Podbielniak (1899–1978), known as Dr Pod. The Podbielniak Contactor was an early and outstanding example of process intensification, giving high throughput in a very short time, and was adopted by Pfizer and others. The Mushroom Man was commemorated with a national heritage landmark. Dr Pod’s company did very well, and production of penicillin boomed. He was annoyed after the war when the US prohibited the export of his contactors to Poland for their penicillin plant.

The war and after

The Manhattan Project had no effect on the war in Europe, as Germany was defeated before any atom bomb was ready. It saved lives by getting Japan to surrender, but not nearly as many as those saved by penicillin. The US had reneged on its agreement to share nuclear know-how, so the UK developed its own atom bombs and nuclear reactors. Many US scientists had been interested in the British information on nuclear power but had been ordered by the government to focus on the bomb. A consequence was that they and other nations developed reactors which could provide material for bombs, and other power technologies were given much less attention until recently.

The Manhattan Project did something to hasten nuclear power, but perhaps not in the best way, and was expensive for what it achieved in the war

In addition, massive amounts of money and people’s lifetimes were devoted to the production and readiness of nuclear weapons which were hoped never to be used. I grew up under the threat of nuclear annihilation as a probability, and it remains a possibility.

However, the penicillin project proved a great advantage to allied forces, both in Europe and the Pacific, including the million men fighting in the jungles against Japan. When the Nobel Prize for medicine was awarded in 1945 it was reckoned it had saved 200 million lives – an amazing achievement in such a short time. With many companies producing, the price dropped rapidly from US$20 to 55c a dose by 1946, and continued to fall.

the penicillin project created a new biotechnology industry and saved the lives and improved the health of billions of people, and must be counted exceptional value for money

Because of penicillin, Selman Waksman (1888–1973) at Rutgers University persuaded the chemical company Merck to fund studies looking for new antibiotics in soil moulds and his team succeeded in 1943 with what became streptomycin. Waksman ruefully reflected that he had seen things like Fleming but had not taken the mental step. Pfizer began similar research in 1945 and found oxytetracycline in 1949. A new research-led pharmaceutical industry evolved, testing thousands of compounds and organisms. Merck, Pfizer, and Glaxo changed from chemical companies to pharmaceutical ones, and a tiny part of ICI Dyestuffs became ICI Pharmaceuticals in 1957, the forerunner of AstraZeneca.

The Manhattan Project did something to hasten nuclear power, but perhaps not in the best way, and was expensive for what it achieved in the war. By contrast, the penicillin project created a new biotechnology industry and way of inventing medicines which saved the lives and improved the health of billions of people, and must be counted exceptional value for money.

Read other articles in his history series: https://www.thechemicalengineer.com/tags/chemical-engineering-history

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.