Project Willow to focus on recycling and bio-feedstock, first official glimpse of Grangemouth future shows

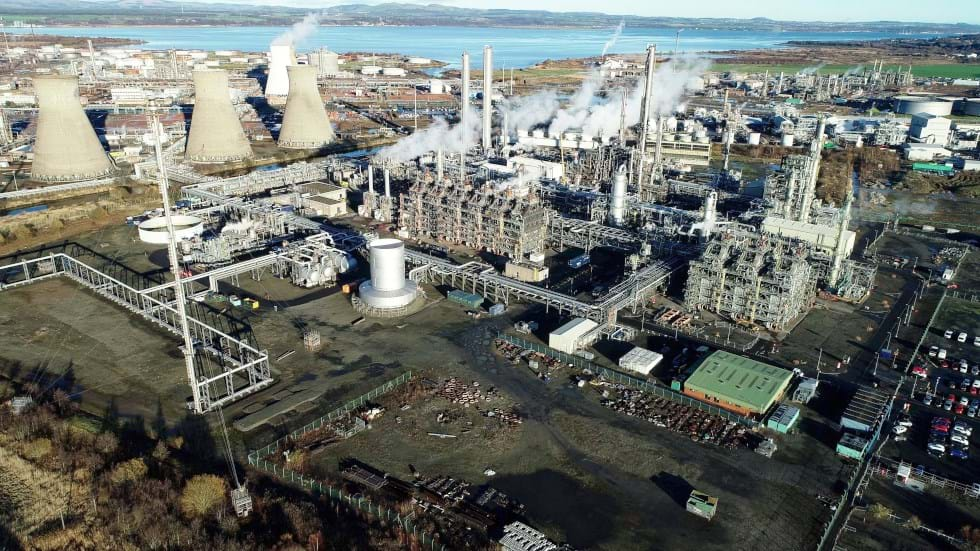

GRANGEMOUTH could host recycling and bio-feedstock production facilities after the site’s oil refinery closes this year, according to proposals published in a report yesterday.

Consultancy EY’s report, commissioned by the Scottish and UK governments for £1.5m (US$1.95m), is the first to provide a detailed picture of Project Willow, the transition plan for the Grangemouth oil refinery in Scotland, which will close later this year with the loss of at least 400 jobs.

EY’s report made nine project proposals, including: hydrothermal recycling to break down hard-to-recycle plastics; dissolution plastic recycling to return plastics to virgin-like status; converting used cooking oil and other waste into alcohols; timber-to-ethanol production; anaerobic digestion for fuel production from animal waste and sewage; SAF production from hydrogenated esters and fatty acids (HEFA) cover crops; hydrogen production to power industrial plants, including sustainable aviation fuel (SAF) and ammonia factories.

The report was produced for the Grangemouth refinery’s owner Petroineos, who announced last year that the refinery would close in the second quarter of 2025 due to ongoing losses from their refining operation.

The report comes after the UK government promised a £200m investment for Project Willow last month.

UK government energy minister Michael Shanks said: “We committed to leaving no stone unturned in supporting an industrial future for Grangemouth delivering jobs and economic growth.

“We will build on Grangemouth’s expertise and industrial heritage to attract investors [and] secure a long-term clean energy future.”

The UK and Scottish governments are now trying to attract private sector investment. Prime minister Keir Starmer previously said he aims to attract £600m from the private sector.

Time and money

EY’s proposals are dependent on the government accepting the report’s recommendations, including energy market reform to reduce renewable energy costs, and an exemption to the cap on SAF feedstocks derived from HEFA, which was included in the government’s SAF mandate last year.

The capital investment required for each of the nine projects varies significantly, from as little as £15m for the anaerobic digestion project, to up to £2.1bn for the hydrogen-powered methanol production project. The anaerobic digestion project would have the earliest start date of all nine, becoming operational by 2028. The methanol plant would not be operational until 2035.

EY estimates all projects would contribute to total UK emissions reductions of just 0.4% compared to 1990 levels. However, individual sectors could benefit from more significant carbon savings, such as shipping emissions which could be reduced by more than 5% with low-carbon ammonia produced at Grangemouth.

Wait for jobs to go on

EY estimates that Project Willow could create up to 1,100 long-term jobs at Grangemouth by 2040. However, it will be years before most of the expected operational jobs arrive, with most of the first construction jobs not expected until 2027.

According to the report, the number of jobs on the site would only exceed 400 – the number of jobs that will be lost when the refinery closes this year – by 2032, and this assumes all nine projects get the go-ahead. Unite the Union has argued that Petroineos’s existing refinery facilities could be converted to a SAF factory and bring operation much nearer. Unite’s Scottish secretary Derek Thomson said: “The options for the future of the Grangemouth refinery need to be fast-tracked to preserve jobs and skills on the site.

“The workers need to see that the political will exists for a decent future for Grangemouth.”

The Scottish government set aside £25m (US$32.4m) last month to expedite the projects identified in yesterday’s report from EY. The UK government has also promised a “training guarantee” for all refinery staff who want skills training at a local college to help them move into new jobs with local employers.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.