Offshore industry has come “perilously close to disaster”, warns HSE

HSE has warned the UK’s offshore oil and gas operators that they must do more to tackle hydrocarbon releases in the North Sea after coming “perilously close to disaster” in recent years.

The warning comes as industry approaches the 30th anniversary of the Piper Alpha disaster. On 6 July 1988, a hydrocarbon release on the platform ignited, killing 167 men. The number and severity of hydrocarbon releases have been a key measure of safety performance ever since, but HSE says despite recent strides to prevent releases there are still too many occurring.

Potential for loss of life

Chris Flint, HSE’s director of energy division, said: “Every HCR (hydrocarbon release) is a safety threat, as it represents a failure in an operator’s management of its risks. I recognise the steps the industry has taken to reduce the overall number of HCRs, however HCRs remain a concern, particularly major HCRs because of their greater potential to lead to fires, explosions and multiple losses of life. There have been several such releases in recent years that have come perilously close to disaster.”

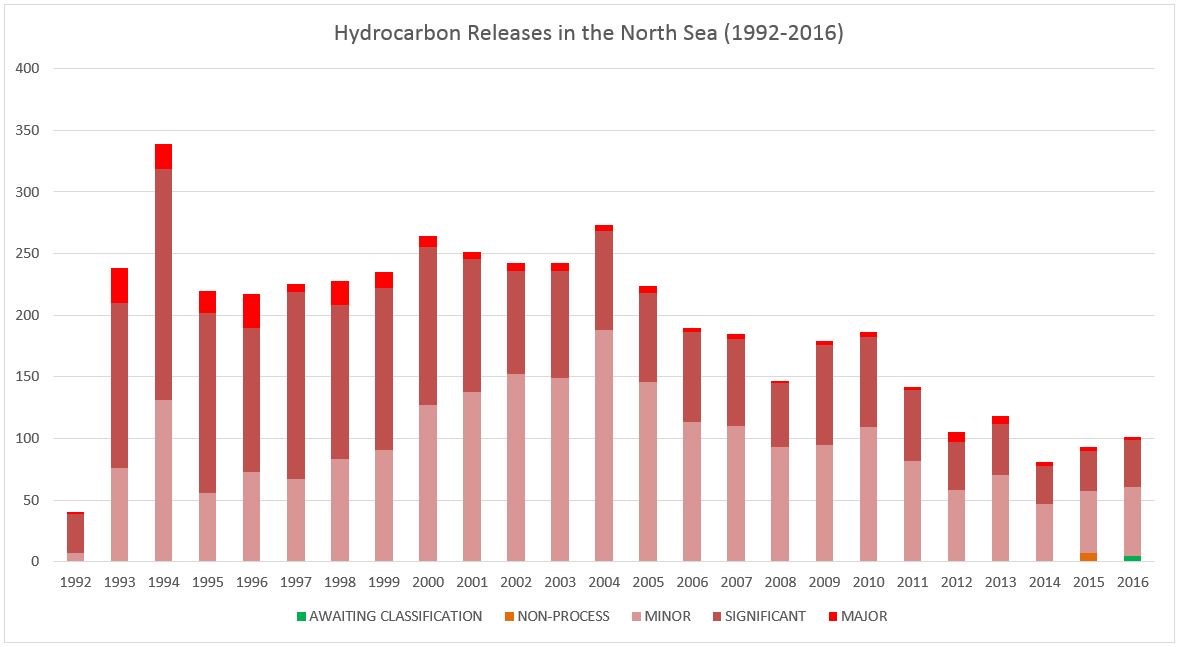

HSE data on releases shows that releases have dropped from 186 in 2010 to 101 in 2016, though that does represent a steady rise from a low of 81 releases in 2014 (see chart).

In a letter sent to all offshore oil and gas production operators in the North Sea, Flint identifies a number of failings that led to releases, and gives industry until 20 July to explain what measures it is taking to improve performance.

Failings across the board

“Experience from our investigations is that HCRs typically happen because there have been failings across the board,” Flint said. “Poor plant condition, and breaches of procedures are often immediate causes, but beneath that we often find a lack of leadership, a poor safety culture, and evidence that weaknesses have existed for some time, but haven’t been picked up through audit, assurance and review and then dealt with.”

Trish Kerin, director of the IChemE Safety Centre, welcomed HSE’s call.

“It is vital for all operators to continue to manage their process safety to eliminate hydrocarbon releases. Every release has a potential for ignition, which can result in catastrophic consequences,” Kerin said.

Operators must now respond, and explain what measures they have put in place since 2015 or plan to put into place to improve safety management performances in the areas of process safety leadership, and audit, assurance and review.

Flint also asks for feedback on how HSE can help encourage more effective sharing of lessons learned from hydrocarbon releases.

Must do better

While the overall number of releases has climbed during 2014 to 2016, the number of major incidents classified as those with the potential to kill and cause impact beyond the local area, has fallen from eight in 2012, to six in 2013, three in 2014, and two for both 2015 and 2016. However, Flint says more must still be done.

“Every year there have been major HCRs with an associated major accident potential, putting the lives of multiple offshore workers at risk,” Flint urges in his letter. “Great Britain’s oil and gas industry must improve further in this area to reduce the likelihood of an incident with potentially catastrophic consequences.”

A high-profile incident at the Elgin platform in 2012 led to a gas escape that continued for 51 days.

Flint also refers to HSE’s revised loss of containment inspection guidance and new hydrocarbon release prevention document produced by the Step Change in Safety organisation. Both were launched at an event in Aberdeen in March to an audience of more than 50 industry leaders, and have been endorsed by Flint as good reference sources.

“If you get the safety culture right, staff will be much more likely to spot hazards, challenge when standards aren’t right, and be engaged in improvement,” Flint said. “And if you have an effective system of monitoring and audit in place, leadership will know which systems need fixing, and can target their efforts to prevent the incidents occurring in the first place.”

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.