Green process converts almost any carbon source into graphene

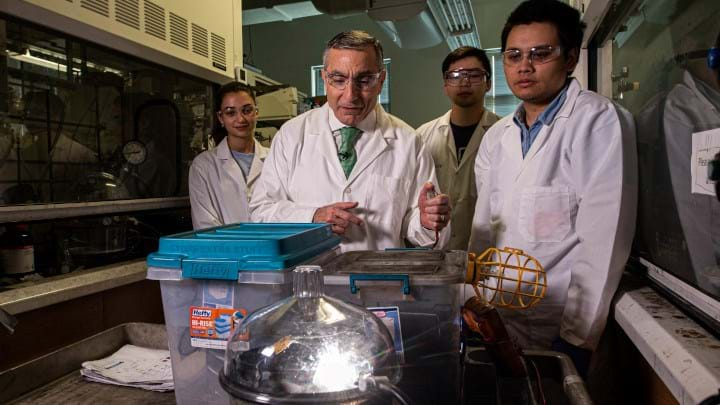

RESEARCHERS at Rice University, US have discovered a green process which can quickly and cheaply produce graphene from almost any carbon source, including coal, mixed plastic waste, biomass, and waste food. It could facilitate a reduction in the environmental impact of concrete and other building materials.

Graphene is the strongest known material. It is comprised of a single layer of carbon atoms arranged in a two-dimensional hexagonal lattice, in which one atom forms each vertex. A tiny amount of graphene can significantly enhance the properties of materials such as plastics, paints, composites, wood composites, concrete, metals, and lubricant. However, it is expensive to manufacture, so has limited industrial applications.

The process discovered at Rice employs flash Joule heating. Joule heating is a process where an electric current is passed through a conductor to produce heat. Using a custom reactor, the Rice researchers can produce graphene in 10 ms. The carbon source is placed between two electrodes and 200 V is applied in a short electrical pulse, heating the material to more than 3,000K (2726.9°C). Non-carbon elements sublime and the remaining carbon atoms reconstruct into carbon.

According to James Tour, Professor of Chemistry and Materials Science and Nanoengineering at Rice, once the process is industrialised, valuable elements such as oxygen and nitrogen could be captured when they exit the flash reactor.

In the flash process, the heat is concentrated in the carbon source. Though the internal temperature exceeds 3,000K, the external walls of the quartz tubes are less than 60°C following the flash process. According to Tour, all the excess energy comes out as light in a very bright flash.

The source material can be anything with carbon content. Tour said that prime candidates are food waste, plastic waste, petroleum coke, coal, wood clippings, and biochar. The yield achieved depends on the carbon source used.

A high carbon content source such as carbon black, anthracitic coal, or calcinated coke can achieve 80–90% yields with more than 99% carbon purity. The researchers discovered that used coffee grounds transformed into pristine, single-layer graphene sheets. Pristine graphene is in its original, pure, and unoxidised form.

Flash Joule heating is the first process to produce graphene with a turbostratic arrangement, as opposed to the more common AB-stacked graphene. This type of graphene is produced by the method used most commonly for bulk graphene production, graphite exfoliation. The layers of turbostratic “flash graphene” are misaligned, resulting in weaker adhesion between layers compared to AB graphene, which makes them easier to separate. They disperse easily in solvents or composite materials.

Tour said that commercial graphene costs US$67,000–200,000/t, but the flash process would be much cheaper, whilst helping to manage waste. According to the researchers, bulk composites of graphene with plastic, metals, plywood, concrete, and other building materials would be a major market for flash graphene. They are already testing graphene-enhanced concrete and plastic.

Adding less than 0.02% turbostratic graphene to concrete increases its strength by 35%, which could enable the same level of structural integrity to be achieved using less concrete. Tour said that this would help reduce manufacturing and transport costs. Furthermore, adding as little as 0.1% of flash graphene into cement used to bind concrete could decrease the environmental impact by a third. In 2015, cement production produced around 8% of global CO2 emissions.

Flash graphene could benefit the environment by providing a use for coal that doesn’t require burning it and reduces the use of expensive materials. Additionally, it leverages materials that would otherwise end up in landfills and converts biomass that would otherwise decompose. All these factors will help reduce the carbon footprint of graphene and lower greenhouse gases.

Tour said: “Essentially, we’re trapping greenhouse gases like carbon dioxide and methane that waste food would have emitted in landfills. We are converting those carbons into graphene and adding that graphene to concrete, thereby lowering the amount of carbon dioxide generated in concrete manufacture. It’s a win-win environmental scenario using graphene.”

Currently the researchers are working to increase production from a few grams per hour to a few tonnes per hour. According to Tour, the researchers have received a grant from the US Department of Energy of almost US$1m over two years. The researchers will use it to try and achieve one kilogram per day of graphene production. Scaleup is to be co-funded by startup Universal Matter. The technology licensee will be responsible for increasing production to a tonne scale.

Nature: http://doi.org/dpmf

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.