Fusion energy advances with AI

Fusion developers relying on power-hungry AI to accelerate commercialisation

FUSION energy development is locked in step with artificial intelligence (AI), according to the findings of a new survey into how companies are using it to rapidly iterate their technology.

There’s a well-worn putdown that nuclear fusion has struggled to shake: that the technology is only 30 years from commercial application, just as it was three decades ago. This could be set to change with a report from the US Clean Air Task Force describing how fusion developers are using AI and high-performance computing (HPC) to accelerate design, materials selection, and control systems in a bid to bring an end to this alleged Sisyphean task.

“Artificial intelligence is advancing at an unprecedented rate, driving demand for clean, firm power,” said Sehila Gonzalez de Vicente, global director of Fusion Energy at the US Clean Air Task Force. “Fusion energy has the potential to help meet that demand with a stable, emissions-free power source that can operate around the clock. We see a unique opportunity for these technologies to progress hand in hand, with AI helping accelerate fusion’s development while fusion provides the clean energy necessary to sustain AI energy demand. This symbiotic relationship could be transformative for technological innovation and the climate.”

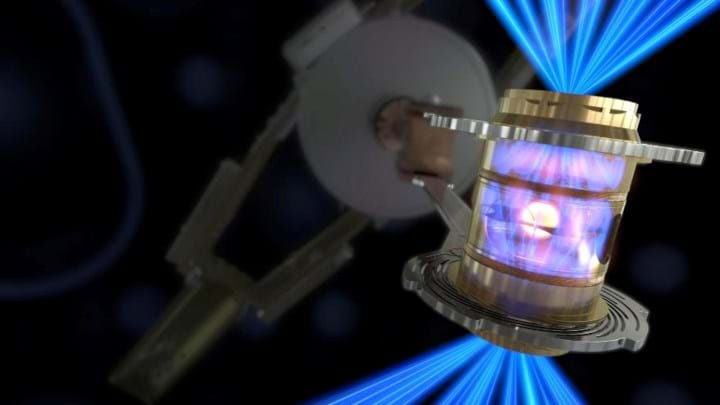

The US Clean Air Task Force has identified five key technologies that can be advanced by AI and HPC. These are materials discovery, tritium breeding technologies, superconducting magnets, inertial fusion energy technology, and advanced diagnostics and control systems. The report includes more than a dozen case studies of organisations using AI technology to speed up development.

Reducing 30 years to 30 months

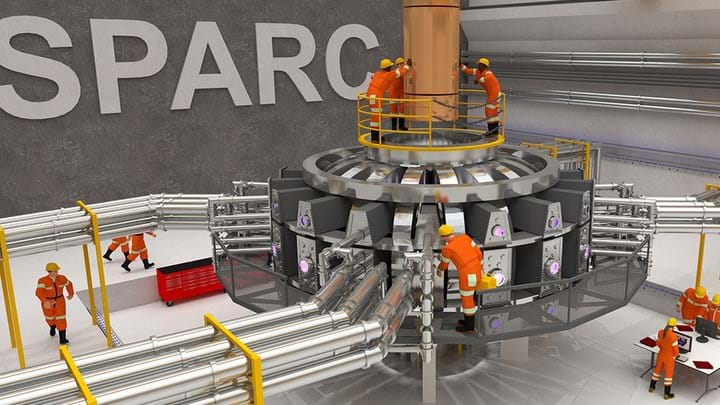

Commonwealth Fusion Systems, which was spun out of MIT in 2018, is using HPC technology to simulate its SPARC demonstration plant. The technology accelerates modelling of particle transport and fluid mechanics. The lessons learned are fed into the next model which then feeds the next, allowing engineers to speed up their design cycles.

Jaydeep Deshpande, principal engineer at Commonwealth Fusion Systems, said: “In the old days, a neutronics model might have taken several weeks – now it takes several days. So, there’s an order of magnitude improvement in getting those insights and incorporating them back into the physical design of SPARC.”

Rick Needham, COO at Commonwealth Fusion Systems, said the process is moving their proof of fusion power “from 30 years to 30 months” away. It aims to achieve net energy gain – getting more energy out of fusion than must be put in to get it started – by 2027. The company has attracted a lot of commercial interest. Total equity investments in fusion have risen above US$8bn, with US$7bn of that invested since 2020. US$2bn of that has been given to Commonwealth Fusion Systems as it pushes to commercialise its technology by the early 2030s.

Systems integration

UK-based company nTtau Digital is offering fusion developers a generative AI product that helps model the interdependencies within fusion systems. The software explores possible designs and runs simulations to produce data that is then used to train surrogate models, which are particularly valuable in cases where experimental or simulated data is scarce. The technology was recently used to optimise tritium breeding while minimising coil design costs, producing previously unexplored designs. The company plans to launch a suite of design and costing tools for fusion plant engineers.

This could be integrated into Nvidia’s Omniverse platform, where engineers can collaborate in a virtual space. This metaverse technology is being used by the UK Atomic Energy Authority (UKAEA) and the University of Manchester in a push to design a plant entirely virtually without physical prototyping. This technology would allow engineers to track every design decision, from the configuration of magnets to the control systems. Once the physical plant begins operations, less optimal choices can be spotted and fed back into the digital model refining future designs, speeding up development and saving costs. Last year, Rob Akers, director of computing programmes at the UKAEA, told TCE that industry needs to take risks on supercomputing if it’s going to overcome climate change at the pace the crisis requires (see TCE 990/991).

This article is adapted from an earlier online version.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.