A virtuous circle? Fusion developers relying on power-hungry AI to accelerate commercialisation

FUSION energy development is locked in step with artificial intelligence (AI), according to the findings of a new survey into how companies are using it to rapidly iterate their technology.

There’s a well-worn putdown that nuclear fusion has struggled to shake: that the technology is only 30 years from commercial application, just as it was three decades ago. This could be set to change with a report from the US Clean Air Task Force describing how fusion developers are using AI and high-performance computing (HPC) to accelerate design, materials selection, and control systems in a bid to bring an end to this alleged Sisyphean task.

“Artificial intelligence is advancing at an unprecedented rate, driving demand for clean firm power,” said Sehila Gonzalez de Vicente, global director of Fusion Energy at the US Clean Air Task Force. “Fusion energy has the potential to help meet that demand with a stable, emissions-free power source that can operate around the clock. We see a unique opportunity for these technologies to progress hand in hand, with AI helping accelerate fusion’s development while fusion provides the clean energy necessary to sustain AI energy demand. This symbiotic relationship could be transformative for technological innovation and the climate.”

The US Clean Air Task Force has identified five key technologies that can be advanced by AI and HPC. These are materials discovery, tritium breeding technologies, superconducting magnets, inertial fusion energy technology, and advanced diagnostics and control systems. The report includes more than a dozen case studies of organisations using AI technology to speed up development.

Reducing 30 years to 30 months

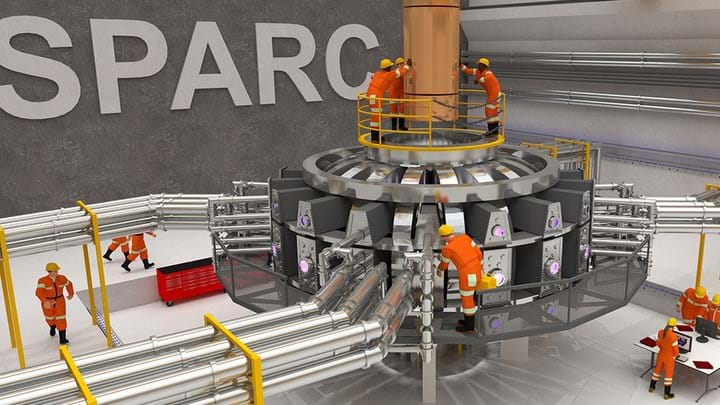

Commonwealth Fusion Systems, which was spun out of MIT in 2018, is using HPC technology to simulate its SPARC demonstration plant. The technology accelerates modelling of particle transport and fluid mechanics. The lessons learned are fed into the next model which then feeds the next, allowing engineers to speed up their design cycles.

Jaydeep Deshpande, principal engineer at Commonwealth Fusion Systems, said: “In the old days, a neutronics model might have taken several weeks – now it takes several days. So, there’s an order of magnitude improvement in getting those insights and incorporating them back into the physical design of SPARC.”

Rick Needham, COO at Commonwealth Fusion Systems, said the process is moving their proof of fusion power “from 30 years to 30 months” away. It aims to achieve net energy gain – getting more energy out of fusion than must be put in to get it started – by 2027. The company has attracted a lot of commercial interest. Total equity investments in fusion have risen above US$8bn, with US$7bn of that invested since 2020. US$2bn of that has been given to Commonwealth Fusion Systems as it pushes to commercialise its technology by the early 2030s.

Systems integration

UK-based company nTtau Digital is offering fusion developers a generative AI product that helps model the interdependencies within fusion systems. The software explores possible designs and runs simulations to produce data that is then used to train surrogate models, which are particularly valuable in cases where experimental or simulated data is scarce. The technology was recently used to optimise tritium breeding while minimising coil design costs, producing previously unexplored designs. The company plans to launch a suite of design and costing tools for fusion plant engineers.

This could be integrated into Nvidia’s Omniverse platform, where engineers can collaborate in a virtual space. This metaverse technology is being used by the UK Atomic Energy Authority (UKAEA) and the University of Manchester in a push to design a plant entirely virtually without physical prototyping. This technology would allow engineers to track every design decision, from the configuration of magnets to the control systems. Once the physical plant begins operations, less optimal choices can be spotted and fed back into the digital model refining future designs, speeding up development and saving costs. Last year, Rob Akers, director of computing programmes at the UKAEA, told TCE that industry needs to take risks on supercomputing if it’s going to overcome climate change at the pace the crisis requires.

Simulating the impacts of design decisions

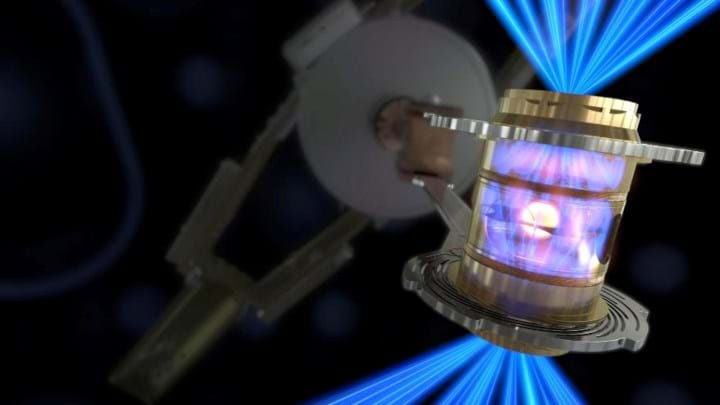

Focused Energy, which is designing laser-based fusion plants, is using generative AI models for so-called cognitive simulation. Jim Gaffney, who was part of the team that achieved breakthrough fusion ignition at Lawrence Livermore National Lab in 2022, explained that “the essence of cognitive simulation is using data to make better models than the one we have”. He goes on to say: “We [use generative AI to] synthetically generate results at every stage of the process and then optimise with the goal of getting to a power plant sooner. Frankly, that would be impossible without AI.

“For example, we can say, ‘Okay, we’re going to do one experiment and make a decision based on it’. Then, we can simulate what the outcome of that decision would be five or ten years down the line. What if we had made a different decision? Would the outcomes be the same, or would they lead to different places? What are the risk profiles for each scenario?”

These models can help teams understand the long-term impact of their choices, assessing the risk profiles of different development paths and optimising decisions for both performance and feasibility, the report notes.

All these simulations do carry significant risks. If the extrapolations are not accurate enough, the real-life machines engineers are steered to build could result in costly failures.

“Fusion can’t afford many wrong turns,” Gaffney said. Moreover, while cheaper than prototyping, simulations remain costly, consuming computational resources that can take days, weeks or even months to complete.

Let me Google that for you

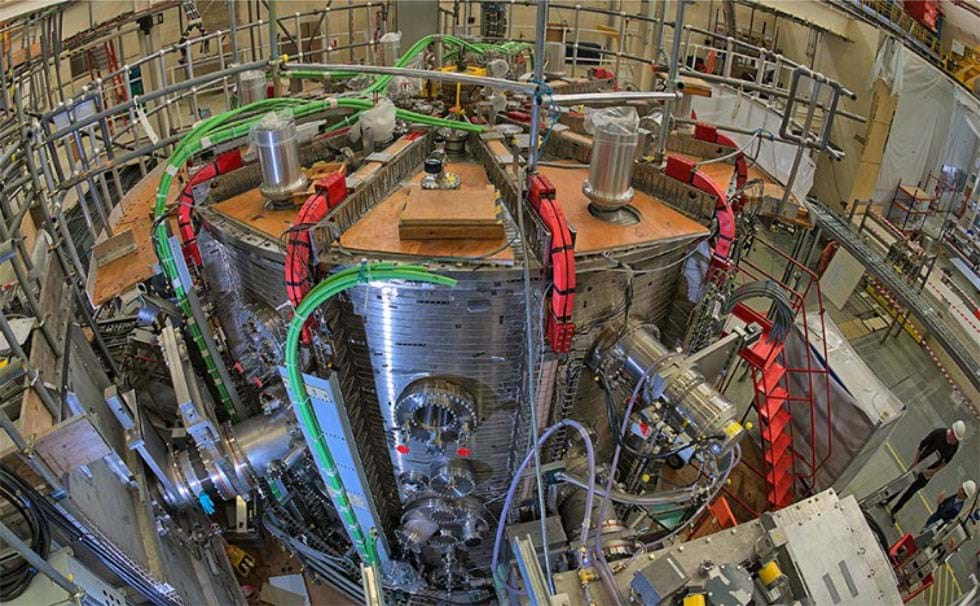

Controlling plasma – the gaseous soup of subatomic particles at the heart of a tokomak fusion power plant – is a critical challenge and one that Google has weighed into. In 2022, its AI division – Google Deepmind – used reinforcement algorithms to demonstrate the first AI-run magnetic control system at the TCV tokomak at EPFL in Switzerland. It transferred a control policy developed during tokomak simulations directly into tokomak hardware demonstrating that AI systems can regulate and respond in real-time to plasma conditions.

Craig Donner, DeepMind principal engineer, said: “This was really the first proof of principle that AI can work not only in simulation environments, but also in complex hardware environments for very fast, real-time control with many inputs and outputs.”

Using nuclear to feed power-hungry AI

Lindsay McQuade, director of energy at Amazon Web Services which sponsored the report, said: “As cloud computing and AI continue to evolve, the amount of energy required to power them is increasing. This makes the exploration of new energy sources, like fusion, more important than ever.”

While fusion proponents predict the technology could revolutionise energy production by offering clean baseload power, just how quickly the technology can help decarbonise the economy is hard to know. The interest in the technology is certainly on the rise with the number of fusion companies formed having quadrupled from ten to 40 since 2017.

Yet a study from engineers at MIT published last month noted that the costs of commercial plants are currently unknown given the current level of technology development. Depending on the costs, the study found that fusion’s global share of electricity generation in 2100 could range anywhere from 10-50%.

What is apparent is the growing interest among tech firms in using nuclear power to feed their power-hungry AI data centres with cleaner power. The IEA has predicted that electricity consumption from data centres and artificial intelligence could double between 2022 and 2026, consuming enough electricity to power Japan.

In September, Microsoft signed a US$3bn deal that could see Constellation Energy restart its shuttered nuclear reactor at Three-Mile Island in the US. Then last month, Kairos Power signed a deal with Google to build a new nuclear plant by 2030 to provide power for its data centres.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.