Engineers publish £22bn blueprint for UK to take global lead on hydrogen heating

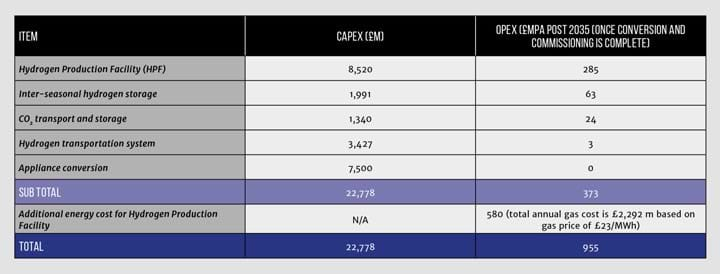

ENGINEERS have called on the UK government to immediately spend £125m (US$159m) designing a hydrogen production, distribution and storage system that would create the world’s largest CO2 reduction project. If realised it would decarbonise 14% of UK heat by 2034, and all told cost £22.7bn.

The H21 North of England plan was presented at the Institution of Mechanical Engineers in London on Friday by UK gas network operators Cadent and Northern Gas Networks, and Norwegian state energy giant and CCS expert Equinor. It’s a more ambitious update to the H21 Leeds City Gate project published in 2016 that established how to convert UK gas networks to carry hydrogen.

The partners suggest the UK builds a 12.15 GW natural-gas-based hydrogen production facility that would feed hydrogen, in place of natural gas, through the existing gas distribution network to industry and domestic users across the North of England. This would include converting some 3.7m meter points in Teesside, Newcastle, York, Hull, Leeds, Bradford, Halifax, Huddersfield, Wakefield, Manchester and Liverpool, representing some 17% of domestic gas connections.

Climate change challenge

The scheme would help the UK meet its legal obligations to reduce emissions by 80% by 2050 against a 1990 baseline. This would be achieved by converting gas networks to hydrogen between 2028 and 2034, decarbonising 14% of UK heat by saving 12.5m t/y of CO2.

Decarbonisation of energy has focussed primarily on power production with the introduction of renewables, but with gas making up around 40% of UK’s primary energy use, efforts are needed on heating if the UK is to achieve its targets.

“The UK still emits 450m t of carbon per annum,” said Dan Sadler, H21 programme director at Northern Gas Networks. “To meet the Climate Change Act target, that needs to be 160m t per annum. So that is a 65% reduction in [2017’s] carbon emissions. And that’s not only enormous in its own right, it’s actually far bigger than you can perceive because we’ve really picked off the low-hanging fruit…so now we’re into the difficult sectors to decarbonise.”

The H21 concept

Speaking on the fringes of the report’s launch, Equinor project director Henrik Solgaard Andersen, told The Chemical Engineer: “This technology is based on proven reference technologies, so all the solutions exist already around the world. The engineering challenge will be putting them together; integrating it as a complete system.”

After studying national energy requirements and proven production technologies, the team has recommended the UK reforms natural gas into hydrogen using autothermal reforming technology coupled with carbon capture and storage to bury up to 20m t/y of CO2 offshore in the North Sea. The £8.5bn production plant would be sited either in Easington or Teesside on the east coast of England, where natural gas from the North Sea is already brought ashore and processed, and would consist of nine 1.3 GW autothermal reformer units operating in parallel.

The design concept for carbon capture involves installing a gas heated reformer in parallel with the autothermal reformer. The CO2 is generated at high pressure, making it more efficient than if released at low pressure in a steam reformer fluegas. The ATR is significantly more compact than a traditional SMR but a large oxygen plant will be needed. The high temperature in the ATR reactor is an advantage, the team writes, as almost all the methane is converted to CO and H2, allowing for a high CO2 capture rate as most of the CO can be converted to CO2 in the water gas shift reaction. The high temperature also allows the reformer to be operated at high pressure, which is an advantage given that the project’s hydrogen must also be delivered at high pressure.

Asked whether there are any key engineering challenges for big industry to overcome in switching to hydrogen, the authors replied that conversion is a market issue not a technical one.

“To give you a great example, SABIC [in Teesside], they have a huge chemical works with 17 furnaces, and 135 burners in those furnaces,” Sadler said. “As part of their chemical process they realised they had surplus hydrogen so off their own bat changed the burners so they could go from 0 to 60% blend hydrogen, so again if you’ve got the availability of the gas, you can develop the burner technology. It’s not a technical issue, it’s having the bulk availability of the gas”

Hydrogen storage and transport

Hydrogen will be produced at a flat rate, so storage is needed to balance supply and demand, and will be especially useful to balance out an increasingly large mix of intermittent renewables on the grid. The surplus hydrogen would be stored in Yorkshire’s deep salt caverns which would avoid the need for re-compression when hydrogen leaves for distribution. The concept provides 8 TWh of inter-seasonal storage, equivalent to installing 62,000 times more storage than provided by the Tesla lithium ion battery recently built in South Australia in response to a series of high-profile power outages.

The system would consist of 56 caverns operating between 85–275 bar along with eight surface facilities. The power required for this inter-seasonal hydrogen storage system would be around 0.073% of the hydrogen supplied.

A new transportation system is needed to connect the production facility and storage system with the existing below 7 bar gas distribution networks. This includes a 80 bar transmission pipeline measuring 520 km long with 23 offtakes, 13 block valves and 50 connection tees; a local hydrogen transmission system operating at a maximum 40 bar pressure and consisting of 334 km of pipelines to distribute hydrogen to strategic points across urban centres; and finally a hydrogen intermediate pressure system comprising 605 km of below 7 bar network mains to allow strategic connections to the existing gas distribution networks.

The authors say the number of plumbers and gas engineers required to convert 3.7m meter points between 2028–35 are well within the UK’s capabilities and the conversion rate is four times lower than when the UK switched from towns gas in the 1960s and 70s. Estimates are that the conversion would add 7% to the average domestic gas bill in 2035, though improvements in home efficiencies are likely to bring this down.

FEED funding

If implemented, the design by default will decarbonise industrial clusters connected to the gas distribution network, and bring about the CO2 transport and storage infrastructure needed to decarbonise those heavy industry sectors where emissions are unavoidable and CCS is the only viable way forward.

Attention now turns to securing the funding from government for a FEED study. The authors have laid out a detailed FEED delivery programme that includes detailed design, on- and offshore surveying, location screening, and 3D modelling. All told it will cost £250m and they are confident they can get private industry to put up half of that. They want the government to commit to funding the rest by next year.

“£250m seems a lot of money but it’s 1% of the overall project total,” said Sadler, noting that the UK is currently considered a world leader in “deep decarbonisation thinking…and the onset of the hydrogen economy”.

“And like any leader, the first mover gets the biggest returns and the biggest rewards,” Sadler said. “If you look at the Danish with wind turbines – [the] first mover is still reaping the biggest rewards. So, this project has the ability to not only meet the UK’s 2050 target in a deliverable system that’s based on proven historic reference technology, but it also has the ability to keep the UK as the forerunner in this space.”

Asked whether the partners have had any feedback from government that would indicate an interest in helping to fund the study, Sadler said “not directly”.

“But what I can say is if you look at the government’s Clean Growth Strategy, it references 100% hydrogen as one of the most credible decarbonisation options.”

On top of this, just days before H21 NoE plan was put forth, the government’s Committee on Climate Change published its own study declaring hydrogen a credible option for decarbonisation but warning that its role depends on early government commitment and improved support.

If the government fails to commit next year, is the project over?

“The government has a legal obligation to meet those [climate] commitments so it’s not about is it over? But it’s the time pressure,” Sadler said. “You have to get onto it now. You have to take a desk-based detailed report and make it into a real engineering project, so when you want to make your decision, you’re not then waiting four years before you can get one spade in the ground.”

“The benefits in H21 are undeniable. Creating tens of thousands of jobs, reusing existing assets, maintaining choice for customers – gas or electric – helping sort air quality issues with hydrogen vehicles alongside electric vehicles, leading the world in decarbonisation strategies that are entirely transferable – and whilst doing all that meeting your climate change obligations.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.