Warm Up Acts

Tom Baxter examines the challenges and opportunities of electrifying process heating

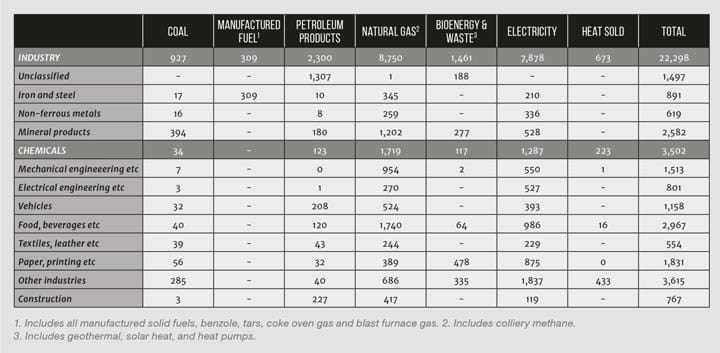

THE chemicals sector is a significant energy user and consequently a direct and indirect contributor to the UK’s GHG footprint (see Table 1)1.

The indirect footprint occurs as a result of the emissions from production of gas or electricity which occur outside of the plant boundary. As is evident from the table, energy use in the chemicals sector is dominated by natural gas and electricity – natural gas being mainly used for process heating through combustion and electricity for electric drives.

Both natural gas and electricity usage for heat and power in the chemical industry will have to be addressed for the UK’s pathway to net zero by 2050. Whilst electricity can be readily made net zero through the use of renewables, the replacement for unabated combustion of natural gas is not so straightforward.

Hydrogen is touted as an obvious substitute as a net zero replacement for natural gas and this article addresses the features of hydrogen or electricity for process heating. Biofuel combustion could also be used but is not addressed here.

Energy costs

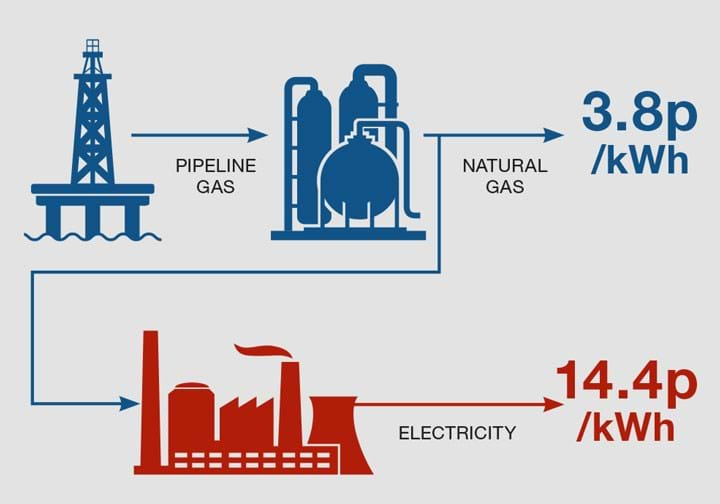

Figure 1 shows today’s cost per kWh for delivery of gas and electricity – costs are taken from UK Power2.

As is easily seen, electricity is four times the cost of natural gas. It is therefore no surprise that natural gas is favoured over electricity for process heating.

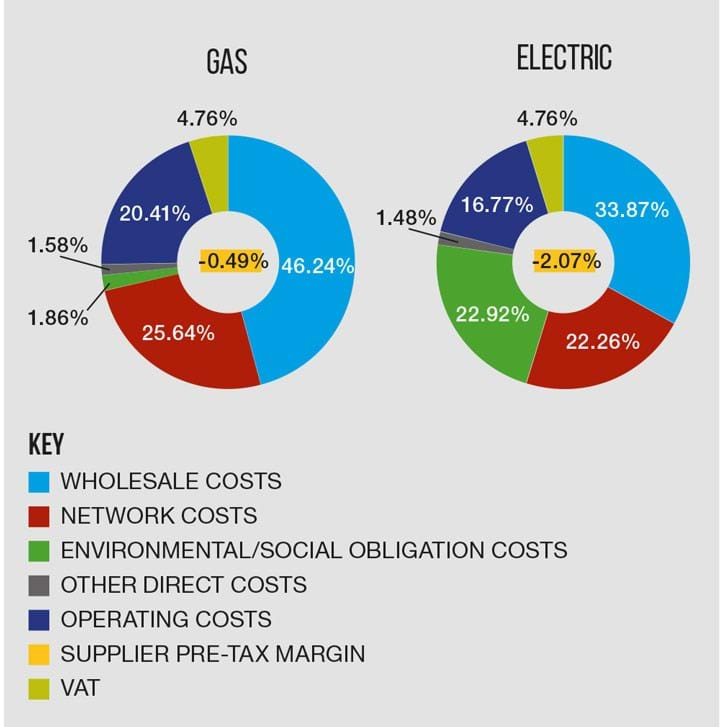

It is notable that electricity presently carries a much higher environmental and social obligation cost than gas. Ofgem data3 is shown in Figure 2. When the UK’s electricity supply has an increasing percentage of renewables, the justification for a 23% environment and social levy compared to 2% for gas is bewildering.

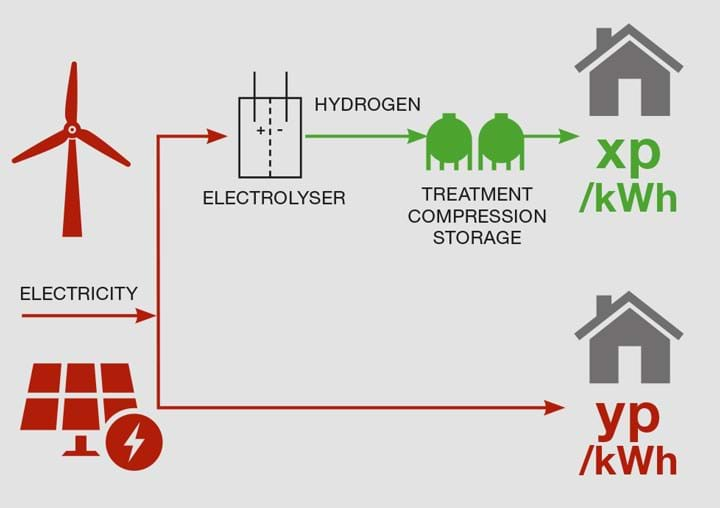

Let’s now move forward a decade or so when many commentators are predicting the use of green hydrogen for heating. Here hydrogen is produced by the electrolysis of water using renewable electricity.

A comparison of future heating options is shown in Figure 3.

The future price of green hydrogen has been the subject of much analysis. However, irrespective of the absolute cost, it seems clear that, on average, green hydrogen cannot be cheaper than the electricity it is derived from. Hence, provided there is a level playing field with respect to green hydrogen and electricity retail tax levies, the future economic evaluation of green hydrogen with green electricity will be very much different from today.

Process heating

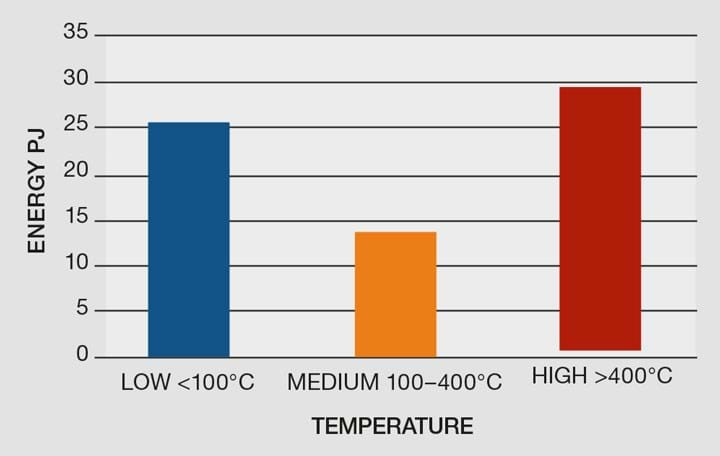

The EU Joint Research Centre’s Heating and Cooling Demand and Market Perspective Report4 provides Figure 4 for the UK. Percentages for low, medium and high temperature heat are 38, 21 and 41%. Hence no temperature range dominates heat demand.

Heating – gas combustion

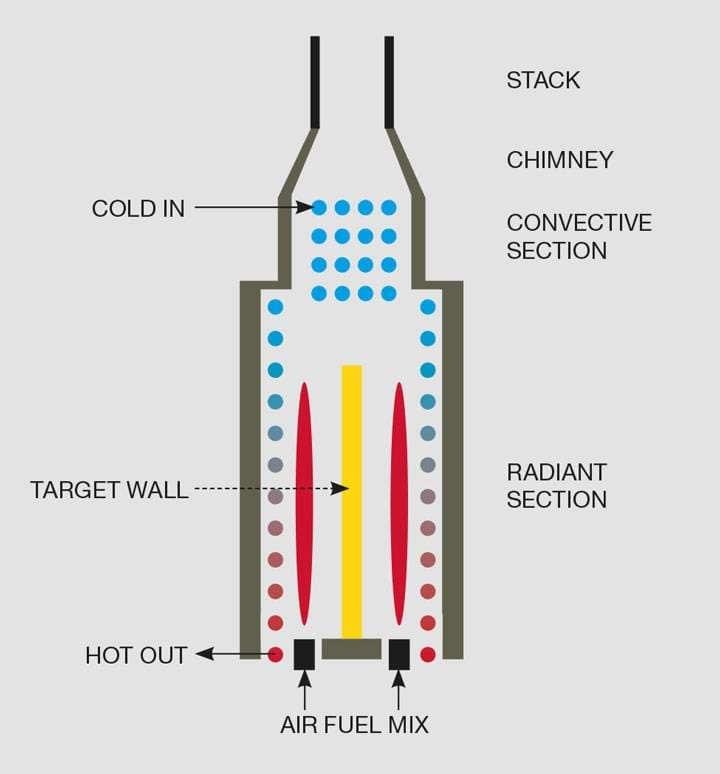

Gas furnaces and boilers are the main forms of gas process heating. Furnaces can be either direct or indirect, where a separate medium is heated and used to impart heat to the process. Furnaces/boilers cover the low- to high-temperature range of process heating applications. Figure 5 recaps the main components of a fired heater.

- Burners: a controlled air-to-fuel ratio is combusted to produce an elongated flame.

- Radiant section: radiant tubes are located along the walls receiving heat directly from the burners and target wall.

- Convective section: the fluid to be heated enters the convection section where it is preheated before transferring to the radiant tubes. As the name implies, convection is the heat transfer mechanism where hot flue gases are used as the heating medium.

- Chimney and stack: flue gases transition to the stack through a chimney section. Emissions measurement is used in the stack to assess the efficiency of the furnace.

A well-designed and operated furnace should achieve a thermal efficiency of around 90-92%. In practice, many furnaces do not achieve these efficiency levels due to poor air/fuel control, poor insulation and lack of integrated fuel/air preheating.

For an existing installation utilising natural gas heating, hydrogen would seem like a simple and attractive replacement

For an existing installation utilising natural gas heating, hydrogen would seem like a simple and attractive replacement. As a consequence of hydrogen combustion characteristics – high flame speed - burner modifications will be required together with control, piping, metering and valving modifications. Fire and gas detection upgrades will be necessary. A Control of Major Accident Hazards (COMAH) revisit will also be required due to the change in risks associated with hydrogen.

Heating – electricity

RESISTIVE HEATING

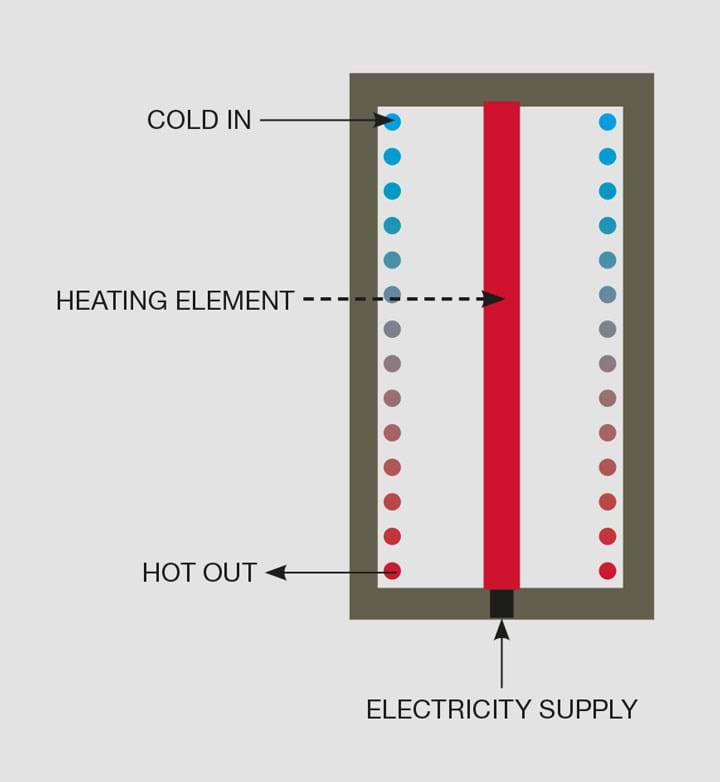

Resistive heating is the most common form of electric heating, it is used for both low and high-temperature applications in food, textiles, printing, chemicals, glass and plastics. The comparison with a fired heater would be an oven (see Figure 6).

Provided the oven is well insulated, efficiencies will approach 100% since there is no fuel and air to heat to combustion temperature or stack losses.

The other most common use of resistive heating is an electric boiler for direct liquid heating or indirectly, for example steam generation.

Electric boilers delivering 20–30 bar steam providing heat at 230°C are readily available5. That is sufficient for many high-energy-consuming reboiler applications in the chemical industry.

High heat load, high temperature resistive heaters, for example for catalytic reforming or cracking, are currently not available. However, it is significant that BASF is developing an 850°C E-Furnace6 that can be used for such high temperature, high energy use applications.

For iron and steel, the 1,500°C electric arc furnace has been used for many decades.

Resistance heating is also reported to be simple to control and carries a lower maintenance burden than combustion equipment.

DECHEMA reports7 a further benefit of electric heating: “In addition to the already described Power-to-X technologies, low-carbon electricity can be used for steam generation in electric boilers replacing natural gas fired boilers. This route is already considered or even operated by large chemical producers, because it can be flexibly employed as a demand-side management measure to use low-cost intermittent power supply from renewables.”

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.