Process Engineering for the Final Frontier

Kathryn Hadler tells Amanda Jasi about the exciting prospect of extracting and processing resources in space

MORE than a century after man first stepped on the Moon, humanity’s fascination with the celestial continues, as we strive to learn more and venture further. Using resources in space could allow just that, supporting travel to the Moon, Mars, and beyond.

We spoke to Kathryn Hadler to learn more about in-situ resource utilisation (ISRU) and the challenges it poses for process engineering. At the time of interview, she was a Lecturer in Mineral Processing at Imperial College London, UK and leading a group focused on mineral processing on the Moon. Now she is the Director of the European Space Resources Innovation Centre, a new focal point for European research, innovation, and community activities in ISRU.

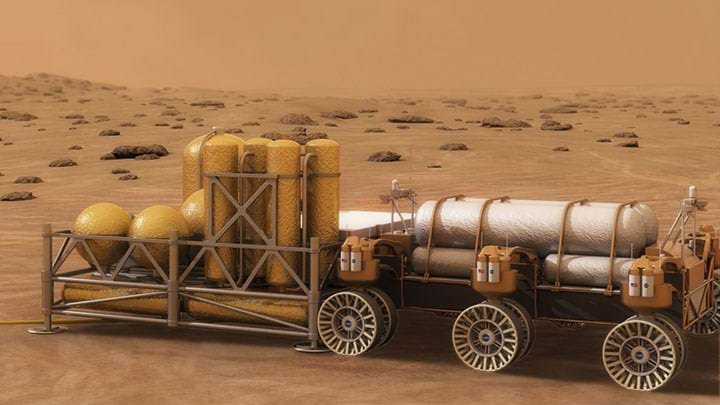

Hadler explains that ISRU is the concept of extracting useable resources in space that can enable further flight or support human life. A primary focus is rocket propellant.

“One of the big problems is that most of the launch mass for a rocket from Earth is spent on escaping Earth’s atmosphere. So, if you can produce propellant for rockets in space then it…reduces the need to take everything that we need with us from Earth. It reduces launch mass which reduces costs, so space suddenly becomes much more economically viable.”

ISRU is the concept of extracting useable resources in space that can enable further flight or support human life. A primary focus is rocket propellant

Oxygen and water are resources of interest, both as propellants and to support human life. Other resources could include construction materials; metals for manufacturing; silicone to create solar panels to harness energy, and power ISRU in turn.

Oxygen on the Moon?

Hadler says the European Space Agency (ESA) is looking to produce oxygen and water from the lunar regolith (soil) via hydrogen reduction or molten salt electrolysis. Currently, it favours the latter for the higher oxygen yields it offers. NASA is focusing on extracting water from ice in the lunar south pole. Many technologies have been put forward for this, including heating it and capturing the sublimed ice.

“There’s such a range of different approaches and different ideas about how we do this,” says Hadler. She tells students in her space mining course that “the great thing about this is that there’s no right answers because we don’t do it yet, so everything is still there to learn”.

However, living off the land is not so easy when in space, and the challenges it presents are “many and varied”.

On Earth, the mining industry uses “huge amounts of water” to separate minerals into the concentrated streams that go off to smelters. A big problem for ISRU is that is has to be done “completely without water”.

“One of the big things that my group are looking at is how to separate the components of the lunar soil, or the Martian soil, dry. So, separate them by size, separate them by type, dry in order to be able to make efficient use of the…downstream reactors.”

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.