Old King Coal Part 3: Coal Chemicals

Martin Pitt looks at how once-discarded byproducts fuelled revolutions in fuels, antiseptics, plastics and road building

TAR HAS been produced from the destructive distillation of wood since neolithic times. Pine wood was placed in a pit and set alight. Lower logs were thereby heated with limited oxygen and tar collected at the bottom. The oldest known dates from about 500 BC near Upsala in Sweden. Pine tar was a major export of the country and the British Royal Navy’s wooden ships depended on what was sold as Stockholm tar to preserve its timbers and ropes. It was with good reason that its sticky sailors were called Jack Tars.

In 1681, German alchemist and industrialist Johann Becher (1635–1682) received British patent 214 for the manufacture of pitch (semi-solid) and tar (viscous liquid) from coal but did not profit from it as he died the following year. In 1780, Scottish inventor and impoverished nobleman Archibald Cochrane, 9th Earl of Dundonald (1748–1831) borrowed £10,000 from his wife and set up the British Tar Company, the first industrial production. His estate had coal and also fireclay, from which the ovens were made. He met with many of the great chemists, metallurgists and industrialists of the day in developing several plants, selling coke, pitch, varnish (carbon black in pine resin and coal tar solvent) and oils. Although many people profited from his enterprise, he did not.

In the 19th century, coal tar appeared with greater quantities as waste product from gasworks. People (and particularly city councillors) who appreciated lighting for streets and business, were less pleased with waste dumped in the river or abandoned on land, so there was an incentive to make something useful.

Tar distillers

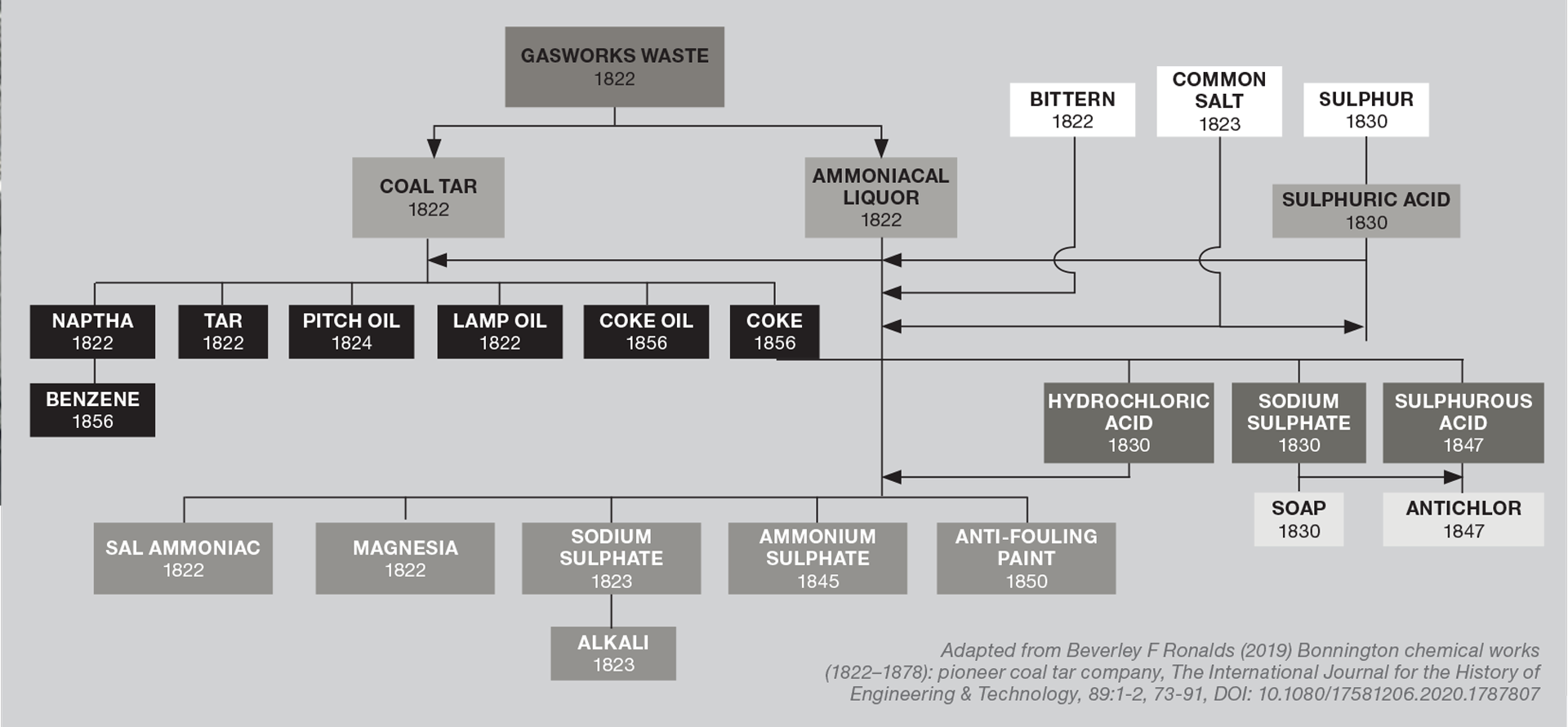

The city of Edinburgh had gas lighting from 1818. The same year, Scottish amateur chemist James Syme (1799–1870) published an account of a material he called naphtha (a general term for any flammable and low viscosity liquid), distilled from coal tar, which dissolved rubber and thereby could make rubber tubing and waterproof cloth. This would later be called benzole. Despite the advice of his friends to patent it, he chose not to. It was Scottish chemist Charles Macintosh (1766–1843) who patented it in 1823, gaining fame and fortune from the raincoat that would bear his name – the mackintosh. John Wilson Anderson (1800–1835), a lecturer in practical chemistry at the University of Edinburgh and a friend of Macintosh, devised the industrial process. In 1822 the Bonnington Chemical Works opened to recover chemical values from Edinburgh gasworks waste, with Macintosh as its main customer. Anderson left academia in 1825 to manage the works, which went on to produce an advanced and comprehensive range of products, including bittern (impure magnesium sulfate used as a coagulant).

“One ton of good cannel coal, when distilled in gas retorts, leaves twelve gallons of coal-tar, from which are produced a pound of benzine, a pound of toluene, a pound and a-half of phenol, six pounds of naphthalene, a small quantity of xylene, and half-a-pound of anthracene for dyeing purposes.”

Daily News, 1894

In 1825, John Bethell (1804–1867), an English lawyer and prolific inventor, set up a tar works in West Bromwich. Others were formed and eventually amalgamated into Midland Tar Distillers. By 1830, the products were: pitch for waterproofing; naphtha and lamp oil; creosote; lampblack (carbon powder) for printing, paint, and a rubber additive; ammonium chloride; magnesium carbonate and sodium sulfate. It ran until 1878. As well as distillation, tar distillers included base treatment to separate acids such as the phenols, acid treatment for base compounds such as aniline and pyridine, and crystallisation for phenol, anthracene and naphthalene. By 1900 some 3m t of coal tar was being distilled worldwide.

In the UK, tar distilling became a major industry but faded as gas was replaced by North Sea gas and coal usage declined. However, China and India still produce millions of tonnes and there are significant industries in other countries.

Pitch (also called bitumen of asphalt)

About half of the tar could be distilled off, leaving pitch. The “twisting” or softening point defined the grade, soft being about 44°C, medium 60°C and hard 100°C. This depended on conditions of manufacture, whether for gas, coke or tar as the main product. Soft was run into barrels, the others into trays, being chopped out after a couple of days. It was used as a waterproofing agent in construction, for example on the black beams of Tudor-style houses in the 19th century, and for roofing, but was often just burnt as fuel at the works. Its great use came with the invention of tar macadam, or tarmac. In 1901, Welsh road engineer Edgar Purnell Hooley (1860–1942) happened across a road where tar had been spilled and covered with gravel to reduce the mess. After some experiments, he got a patent in 1902 for a new road surfacing method, registered the name Tarmac and formed the Tar Macadam Syndicate. The profitability of this improvement on macadam (crushed stones and sand) was helped by cheap and abundant materials: soft pitch (which could be easily melted), furnace slag (a steelmaking waste product) and sand. Modern tarmac uses bitumen from petroleum which gives off less harmful vapours. The term asphalt now refers to the mixture.

In 1888, the first production of aluminium began with an electrolytic process. The anodes were made of coke with pitch as a binder. Pitch is still used today in the manufacture of electrodes for this purpose and electric arc furnaces. It is also a source of carbon for graphite and carbon fibres.

Chemicals

By 1850, chemists had identified significant quantities of benzene, naphthalene, anthracene, aniline, quinoline, pyridine and the phenols in coal tar, but commercial uses were yet to come. By 1900 all were eagerly traded.

Benzole

Benzole was a chemically purified fraction with boiling points in the range 80–150°C containing at least 40% benzene with toluene, xylenes and other hydrocarbons, a very strong solvent. In 1825 English chemist and physicist Michael Faraday (1791–1867) first isolated benzene as part of the liquid in cylinders of illuminating gas made from the pyrolysis of whale oil and determined it contained more carbon than the gas, so called it bi-carburet of hydrogen. It was later made from benzoic acid (named after benzoin resin, a type of incense, from which it was obtained) and named benzene, benzin or benzine, though Scientific American in 1880 called the pure compound benzole. As well as solvent use, benzole vapour converted coal gas to illuminating gas, and mixed with two volumes of alcohol could be used as lamp oil. Later separation of the components gave rise to considerable chemical uses.

Benzole also had a major impact as a motor fuel. In the early 20th century, suitably refined benzole, low in sulfur and gums, proved effective for internal combustion engines. After World War One, surplus benzene and toluene supplies led to the creation of the National Benzole Company in 1919, whose 70/20/10 benzene-toluene-hydrocarbon blend became a popular anti-knock additive. Similar mixtures, marketed by OLEX in Germany, outperformed low-octane petrol and gave rise to the term benzin. Concerns over the health hazards of aromatics in the 1950s led to its replacement by tetra-ethyl lead – later itself recognised as highly toxic (see TCE 981: A Short History of Unintended Consequences).

Creosote (pitch oil)

German polymath scientist and industrialist Karl Ludwig von Reichenbach (1788–1869) studied the products of wood and coal tar distillation from 1830 to 1834. He correctly identified a fraction boiling over 200°C as containing the preservative ingredient in wood smoke and the name creosote was given from Greek to mean flesh-saver. It became used as lamp oil, an antiseptic and insecticide. In 1838 John Bethell (1804–1867) patented a method of impregnating wood with creosote under pressure which became used internationally, particularly on railway sleepers and telegraph poles, and made him a fortune.

The composition varies, but it contains cresols (hydroxytoluene), some phenol and a range of aromatic compounds. The addition of NaOH and soap produced liquid which dispersed in water (as a milky fluid) used as a sheep dip, added to baths in hospitals, and widely used as a disinfectant. By 1890, English production exceeded 13m L/y. Its components also contributed to synthesis of a variety of chemicals and dyes.

“I worked on a chemical plant which had once been part of the company Midland Tar Distillers, but where we now made chemicals synthetically. I learned as part of the history that the old site had benches where children with tuberculosis were brought to sit and inhale the fumes of creosote. Sadly, inhaling disinfectant did not deal with the infection.”

Martin Pitt

Phenol

In 1834 German analytical chemist Friedlieb Ferdinand Runge (1794–1867) named a crystallisable extract of coal tar Karbolsäure (coal-oil-acid), which became carbolic acid in English. In 1843, French chemist Charles Frédéric Gerhard (1816–1856) named it phénol, following its identification as a derivative of benzene, known in France as phène. It was extracted from “carbolic oil” into water by NaOH as the salt, then released by acid treatment and crystallised. In the 1860s, two surgeons in particular, Jules Lemaire (1814–1873) in France and Joseph Lister (1817–1912) in Britain developed and promoted its use in solution as an antiseptic (see TCE 1,008: How Soap was Born).

In the 1860s relatively pure phenol began to be produced industrially by crystallisation. German-born British chemist Hermann Sprengel (1834–1906) specialised in safe explosives, and in 1871 demonstrated that triply nitrated phenol (picric acid) was a high explosive which produced very little smoke. It became the standard for British artillery shells, becoming a major use of phenol and a critical war material (see TCE 969: The Explosive Foundation of IChemE to read about The Great Phenol Plot).

In 1872 German chemist Johann Adolf von Baeyer (1835–1917) observed that phenol and formaldehyde could condense to form a resin. This was taken further by Belgian chemist Leo Baekeland (1863–1944) who in 1907 patented the pressure process by which it hardened under heat without foaming, giving rise to the first synthetic plastic, Bakelite. Plastics are now the major use, with synthesis from petroleum being the main source. It is also used in dyes, pharmaceuticals and other chemical products.

Naphthalene

This is two benzene rings fused together melting at 80°C, boiling at 218°C but tending to sublime from the solid, typically 10% of coal tar. The name was unimaginatively given from the liquid naphtha by English chemist John Kidd (1775–1851) in 1821. It was a problem for gas works because it could deposit from the gas and clog joints, valves and meters, but had no obvious market. A boost came in 1890 when a lamp was produced using it, though this went out of fashion. The solid was used as mothballs, its vapour being lethal to insects in a confined space. Farmers also used it in storage and seed drilling against moths and insect pests. It could be burned along with pitch, and in Germany, engines ran on it in liquid form. However, it turned into a very desirable material as its chemical uses were discovered, initially for dyes but later for plastics and explosives. From the 1960s to 90s it was mostly made from petroleum but now the majority comes from coal, more than a million tonnes a year.

Anthracene

This is three benzene rings joined together in a row, obtained from a higher boiling fraction than naphthalene, named in 1835 by one of its discoverers, French chemist Auguste Laurent (1807–1853), from the Greek word for coal, anthrax. It found use for dyestuffs.

Paraffin

In the mid-19th century, Scottish chemist Robert Young showed that low-temperature pyrolysis of coal yielded a lighter oil fraction containing acyclic hydrocarbons, which he called paraffin oil. From this he separated a clean-burning lamp oil and a wax suitable for candles, patented in 1851. Young later switched to oil shale as his coal supply dwindled, and his company prospered until cheaper petroleum products displaced paraffin after 1919.

Some of the minor components will be dealt with in the next part of our coal journey.

Martin Pitt CEng FIChemE is a regular contributor. Read other articles in his history series: https://www.thechemicalengineer.com/tags/chemicalengineering-history

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.