HyNet: Demonstrating an Integrated Hydrogen Economy

HyNet North West is a combined hydrogen energy and carbon capture, usage and storage (CCUS) project, the immediate goal of which is to reduce carbon emissions from industry, homes and transport and support economic growth in the North West of England. However, HyNet North West has a more strategic series of objectives, which are to demonstrate the individual elements and provide and prove both hydrogen and CO2 infrastructures to act as a stimulus for other low carbon development into the future.

Why the North West of England?

The North West of England is ideally placed for a futuristic project like HyNet. The region has a proud history of bold innovation, and today, clean energy initiatives are thriving (eg road and rail transport). On a practical level, the concentration of industry, existing technical skill base and geology (including a depleting oil and gas field close to shore) means the region offers an opportunity for a project of this kind. It has ample infrastructure and a massive potential for growth and innovation. It also benefits from forward-looking local government with a genuine appetite to be leaders in reducing their carbon footprint.

Home to Stanlow, the second-largest refinery in the UK, CF Fertilisers, Ineos, and Solvay, the region has much experience in production and utilisation of hydrogen.

Hydrogen production

Analysis, carried out in mid-2016 for National Grid Gas distribution (now Cadent Gas) identified natural gas as the only practicable source of primary energy from which hydrogen could be derived in sufficient quantities able to meet the expected demand in a short timescale (within ten years), and have the potential to meet the requirements of being classified as “low carbon”. The role of electrolysis from renewable sources is acknowledged, but it was appreciated that there was still some way to go to decarbonise the electricity industry, and decarbonising heat as well would require an unrealistic expansion, for instance, of offshore wind or nuclear power.

Potential technologies were assessed by Progressive Energy, and autothermal reformation was identified as being the best, given the requirement for CO2 capture, high product purity, and high overall efficiency.

Natural gas is first stripped of remnant sulfur species, preheated, then reacted sub-stoichiometrically with oxygen under pressure to form syngas, which is mostly carbon monoxide (CO) and hydrogen (H2). This is very hot and is cooled against the incoming natural gas. The syngas is saturated then shifted, resulting in a product comprising almost entirely of CO2, H2 and unused water. Finally, using a proprietary acid gas removal process, the CO2 and water is separated out, leaving just the hydrogen.

This process, which was featured in more detail in “Clean Hydrogen. Part 1: Hydrogen from Natural Gas Through Cost Effective CO2 Capture” on the online edition of The Chemical Engineer, is fully scalable, placing the UK in the forefront of large-scale hydrogen production with associated CCS.

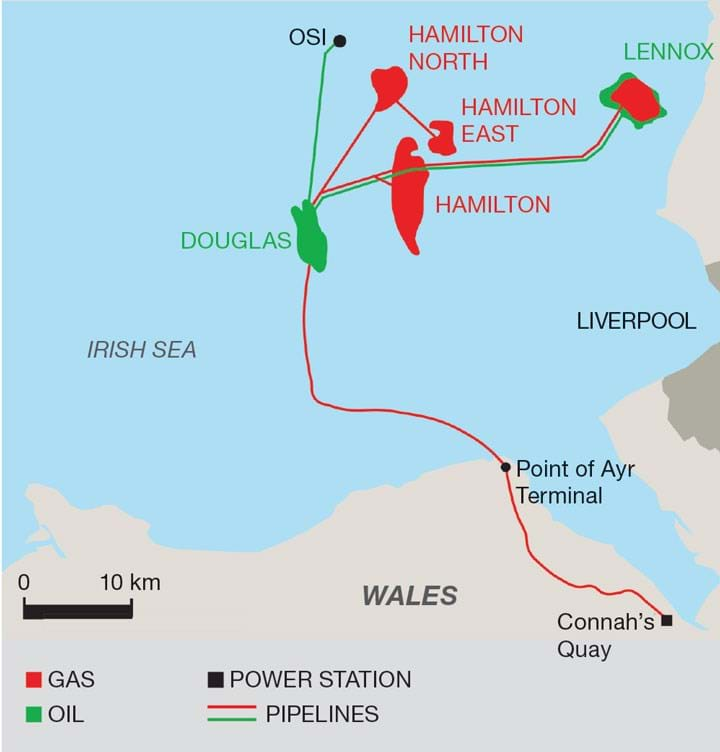

CO₂ disposal

Previous CCS projects have all focussed on disposal in the North Sea. This implies long pipelines, deep waters and some of the harshest weather conditions in the world. HyNet North West is different: the Liverpool Bay fields are close to shore, in shallow waters and sheltered by the surrounding landmasses. Although the fields are some 30 km offshore, there is an existing pipeline infrastructure, currently bringing in natural gas, and a further 30 km on-shore pipeline (see Figure 1). Another ~30 km will be required to link this to where the hydrogen would be produced. The CO2 would be transported in the gas-phase on land and initially offshore, eventually transitioning to dense phase as additional CO2 sources are brought on line.

Disposal would be in the geological structures associated with the Liverpool Bay oil and gas fields, which are expected to be depleted within the timescales of the HyNet North West project. The CCS infrastructure would initially operate by receiving CO2 which is currently being emitted to atmosphere by some of the local industries, bringing an early win to the producers.

CCUS is a vital technology to achieve the widespread emissions savings needed to meet the 2050 carbon reduction targets. The HyNet North West project will demonstrate simultaneously:

- multi-source collection of CO2 from diverse industrial sources (eg fertiliser production, cement manufacture, petrochemical refining);

- new-build CO2 pipeline design, construction and gas-phase operation;

- repurposing of an existing on-shore natural gas pipeline to take CO2;

- repurposing of an existing off-shore pipeline to take CO2 in dense phase;

- dense phase CO2 operation and lower pressure injection into subsea strata; and

- re-use of offshore natural gas production infrastructure for CO2 disposal.

Hydrogen market development

A significant proportion (53%, excluding transport) of the UK’s heat is derived from the combustion of natural gas2. Of this, over 96% is used for high and low temperature processes and space and water heating3. Were this to be replaced with hydrogen, there would be a significant reduction in the associated emissions of CO2. HyNet North West proposes to develop this market in a number of different ways:

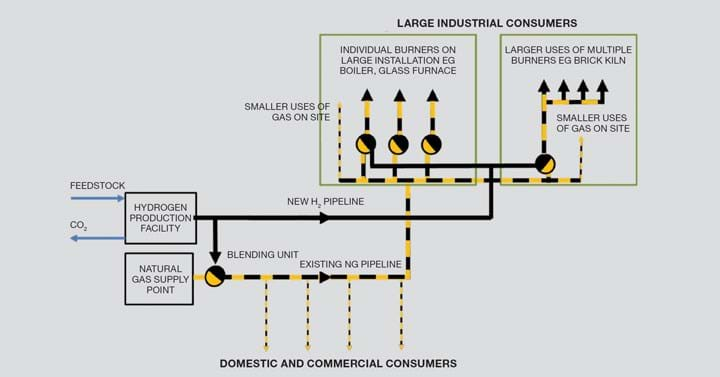

1. Substituting, in whole or in part, for natural gas in large industrial processes. The North West is home to some heavy users of natural gas, for instance in glassmaking furnaces, brick kilns, and large industrial steam and hot water boilers. HyNet North West is working with such industries to find out how much hydrogen can be substituted for natural gas without adversely affecting the product, the process or the environmental performance. A modest investment can deliver significant reductions in CO2 emissions for high hydrogen operation, making an important contribution to “greening” a company’s production facilities, and establishing world-class environmental performance.

2. The success of the UK's HyDeploy programme has shown that introducing up to 20% hydrogen into the natural gas supplies has a negligible impact on its combustion properties, and is no less safe. A second market for hydrogen can therefore be realised by introducing it into the low pressure natural gas system, enabling every home and every commercial premises to make a contribution to the national CO2 reduction programme. Because of the negligible impact on the combustion properties, this would not require the replacement of any equipment, and would be at zero cost to the vast majority of customers. And if, for some reason, the scheme were not to work, there would be no re-conversion cost to revert to natural gas once again (ie a “no regrets” approach).

3. Hydrogen-burning gas turbines have long been a dream of the manufacturers, opening the door to a reliable, predictable, carbon-free electricity supply. With the arrival of low carbon hydrogen in bulk quantities, this potential can be realised. More details on this can be found in a recent article on their development4, and this application is expected to open up another significant market in the North West (and elsewhere in the UK and internationally growing from it).

4. Transport applications, particularly for trains and larger vehicles (vans, trucks, buses), are being trialled in the North West, and the availability of a dispersed hydrogen distribution infrastructure will facilitate this. HyNet has the potential to offer this, by offering trunk hydrogen pipelines from which branches to “filling stations” can be attached.

Hydrogen Transportation

In June 2019 The Chemical Engineer published a report on the options and challenges of transporting hydrogen5. It concluded that pipelines represented the best option for bulk transport, and that applications requiring very high purity hydrogen (eg fuel cells) could benefit from local purification. HyNet envisages a hydrogen transportation system based on an arrangement shown as Figure 2.

The overall HyNet North West vision

The Hynet North West vision consists of three phases:

Phase 1: Building the evidence (2018–2023)

- Technical, cost and practical evidence to inform government heat and carbon capture policy.

- CCUS infrastructure created for industrial CO2.

- Customer experience of blended hydrogen through the related HyDeploy project.

Phase 2: Project Delivery (2023–2026)

- Hydrogen infrastructure in place.

- Supply high hydrogen to industry.

- Supply blended hydrogen and natural gas to homes.

- CCUS infrastructure operational.

- Over 1m t CO2 captured and stored every year.

Phase 3: Extension (2027–2035)

- Hydrogen supply extended to wider geography and for flexible power and transport.

- Realise opportunities for lower-cost H2 and “negative emissions” via bio-energy with CCUS.

- Hydrogen transport fuelling network in place.

HyNet – Gathering serious momentum

The engineering of the HyNet project is making significant progress. Pre-FEED work is complete on the hydrogen production plant design and combustion testing (up to 100% hydrogen on a glass furnace burner, and on a package boiler, typical of over 80% of the industrial designs in the UK). This work is currently in FEED.

Pre-FEED work is complete on the CO2 export pipeline and storage (including flow assurance) and on a number of industrial capture sources. In parallel, the pre-FEED study on the hydrogen distribution system is well advanced with clear identification of demand profiles, network topography and storage requirements to manage variability in supply and demand.

In many respects, engineering HyNet is the simplest hurdle to be crossed – there is nothing in the HyNet vision that cannot be delivered with existing technologies and competent engineers. The biggest challenge is ensuring that a market framework is developed by government which makes HyNet an investable proposition.

We are at the stage of HyNet where we are transitioning from desktop studies to large-scale infrastructure delivery, and this requires serious investment to undertake surveys, consultations and secure consents.

The UK Government’s level of focus in this arena has changed out of all recognition in the last 18 months, driven in large part by the Net Zero commitment and the recognition at all levels of government that hydrogen and CCUS is a necessity, and not an option. This has led to a political commitment to deliver investable business models for hydrogen and CCUS by the end of 2020, alongside with material levels of grant funding, and this will catapult HyNet into the execution phase.

HyNet stands ready to be the first, lowest-cost and lowest-risk integrated hydrogen/CCUS project in the UK, delivering a low carbon industrial cluster in the North West by the mid 2020s and building the infrastructure for whole-scale low carbon transformation of the hard-to-reach sectors of the economy.

References

1. From BHP Billiton Petroleum and Operational Review 2006

2. Adapted from Figure 4, Transitioning to Hydrogen, assessing the engineering risks and uncertainties, IET, May 2019

3. Adapted from Figure 8, Transitioning to Hydrogen, assessing the engineering risks and uncertainties, IET, May 2019

4. https://bit.ly/3fAiFyr

5. https://bit.ly/2Linej8

6. From HyNet North West, from vision to reality, Cadent Gas, v5, May 2018

This is the 19th article in a series discussing the challenges and opportunities of the hydrogen economy, developed in partnership with IChemE’s Clean Energy Special Interest Group. To read more from the series online, visit the series hub at https://bit.ly/2z4wJ2W

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.