Hydrogen: Making the Case through Life Cycle Analysis

How decisions on hydrogen’s role in energy systems might be made; industry collaboration and long time-horizon life cycle analysis could be the first step.

THE UK’s pledge to reach Net Zero Carbon before 2050 has been primarily planned around decarbonising the electricity supply, leading on to the electrification of heat and transport, eg through domestic heat pumps and electric cars, trucks and trains.

A big challenge for the latter part of this approach is the fact that the additional energy demands for heating and transport are together more than four times the current electricity supply.

To deliver such an increase of electricity, whilst bringing emission to Net Zero Carbon, will require bringing more renewable energy from increasingly remote sites; a proportionately large expansion in transmission lines; a massive roll-out of new electrical technology on streets and in homes; and large capacity energy storage to buffer between renewable supply and demand cycles.

The large investment needed will not only be in terms of money but also in the amount of the Government’s carbon emissions budget and other mineral resources (some rare) that will be used up just to build all these new facilities. It is important that the ecological suitability of what we build is part of the decisions we make about our future energy systems.

It is in this light that many stakeholders, including the Institution of Chemical Engineers’ Clean Energy Special Interest Group, have identified hydrogen’s potential as an alternative energy vector that can be competitive and complementary to electricity. They are suggesting that utilising hydrogen as a fuel for heating, transport and industry and as a means of energy storage and long distance transmission may provide ways to ease the transition to Net Zero Carbon.

One particular feature of hydrogen that may make it attractive is its potential to reuse existing fossil fuel infrastructure that would otherwise be abandoned were we to go all electric. Repurposing rather than scrapping these long-established systems will help hydrogen options be less disruptive and resource hungry, and potentially more cost effective to install.

The optimum energy system arrangement could be one where hydrogen and electricity vectors compete and interchange via commercially-available electrolysers and fuel cells, each playing its most effective role.

Such a two-vector approach, able to adapt existing infrastructure and draw engineering resource from our existing fossil fuels industry, might enable a more resilient quicker transition to net-zero carbon than might be the case if we rely on electricity alone.

Handling hydrogen safely is nothing new to engineers in the chemical and oil refining industries. There is vast experience of transmitting gas safely by pipelines – both onshore and offshore – that reside with utilities and oil and gas industries. Indeed, new infrastructure projects to transport hydrogen to domestic and industrial users (and associated carbon capture and storage) could herald a new era and a boost in activity for workers currently employed in oil and gas, chemical and other industries, as fossil fuel-based systems are gradually phased out.

Government support and at-scale demonstration

In its 2018 report on hydrogen, the UK’s Committee on Climate Change (CCC) identified that hydrogen can be a strong complement to electrification and wants to see whether its technical and economic worth can be proven by operation at scale.

Demonstration projects that reflect this aim – to justify a real foothold for hydrogen, support its links with CCS and test its safe use in existing infrastructure – are now under way in several potential hydrogen cluster regions as a result of support by Government grants.

How do we decide on hydrogen?

Given the country-wide nature of the task and the need to schedule the planning permissions, wayleaves and works whilst maintaining supply, the opportunity window to extend or convert the energy network to deliver the UK’s target of net zero carbon emissions by 2050 is, in fact, relatively small.

If hydrogen is to play a part then we need to know as quickly as possible that it can be delivered safely and in which functional roles and circumstances it might perform better – technically, ecologically and economically compared with electricity. A possible set of criteria for assessing this is shown in Box1.

Box 1: Techno-economic and life cycle criteria to compare hydrogen systems with their electrical counterparts

- Safety.

- Technical readiness (and development activities still required).

- Technical life of components within the system.

- Commercial availability and speed of deployment.

- Whole-of-life environmental impact.

- Capital and operating costs – cashflow needs.

- Resource availability – the technology must be deliverable within the limits of the main materials (including critical materials) that it would need.

- Location of the skillsets, training, and manufacturing facilities that could be capable of delivering the solutions plus business opportunities and export potential created.

- Impact on natural capital and biodiversity.

- Planning permission and regulation approaches.

There is now considerable activity from which evidence for such assessment can be drawn:

- UK hydrogen demonstration projects – which are all striving to get to the point where investors engage (FID).

- Utility companies and safety consultants – who are studying transport of hydrogen by reusing existing networks.

- Trade and academic institutions – which are setting out their position regarding hydrogen.

Now would be an excellent time for these stakeholders to agree to collaborate and use their outputs to form a consensus view on how hydrogen might best be used, alongside electricity, in future energy systems.

Whilst there is not yet all of the technical, cost and operation data to form the full assessment, there should now be sufficient mass and energy balance, and equipment supplier information from the front end engineering of hydrogen demonstration projects for life cycle or ecological comparison of hydrogen versus electricity-based systems to commence.

The idea would be not to compare project vs project or region vs region but, with the agreement of the companies involved, to draw data that would enable generic study of electricity vs hydrogen on individual functions within an energy system.

A generic consensus view on the ecological case might provide the first "stake-in-the-ground" signal to stimulate manufacturers and investors to engage with hydrogen’s role in future energy systems.

Energy system functions where hydrogen can contribute

Suggested generic functions that could be assessed include:

- The different ways that hydrogen can be generated in bulk for introduction into such an energy system, comparing: the various “grey” hydrogen processes making H2 from natural gas but without capturing carbon emissions; “blue” hydrogen – using these processes but with carbon dioxide captured then stored or reused; and “green” hydrogen – generated by renewable energy sources without producing carbon dioxide in the first place, eg using renewable electricity to electrolyse water. The outputs from these assessments would play a part in the assessment of any of the cases below where hydrogen is raised as part of the function.

- Transmitting energy across land by invisible buried pipelines rather than overhead transmission lines – potential for faster planning approval and lower capital cost.

- Bringing “green hydrogen” onshore by electrolysing water offshore then in a hydrogen pipeline (possibly repurposed redundant existing line) as a possible alternative to undersea HVDC cables.

- Considering the chemical industry’s ~40 years’ experience of balancing hydrogen production and use via storage in salt cavities, combined with fuel cells to provide both frequency response and short-term operating reserve (STOR), and maximising efficient delivery of renewable energy against other techniques proposed to buffer the national grid.

- Raising hydrogen then blending it (~20%) into the existing natural gas network with the aim of achieving a small (~3%) but rapid reduction in emissions from heating systems at low capital cost and with minimum disruption to existing assets.

- Using H2 as a long-distance transport fuel – particularly for trains and trucks and in low population areas – an aspect of transport that can be a challenge to electrified vehicles.

- Using hydrogen as a more ecologically sound alternative energy source for energy intensive industrial processes – eg through direct reduction of iron ore.

Proposed goal and methodology

As our goal is to establish the most viable, lowest carbon route to a net zero carbon energy system which, like its current counterpart has, will need to provide a stable long-term backbone service to the country’s economy in 2050 and beyond, our choice needs to be focussed on long-term economic and ecological impact rather than short-term payback.

Our assessment needs to be based on at least the 30 years from 2020– 2050, if not longer – perhaps 2020– 2100, an 80-year time horizon.

With such a long time horizon, components involved will need to be replaced – some several times, and these studies will need to account for all cradle-to-grave ecological impacts, costs and resources, ie taking account of manufacture, installation, operation and maintenance to decommissioning and disposal for each time a component is replaced.

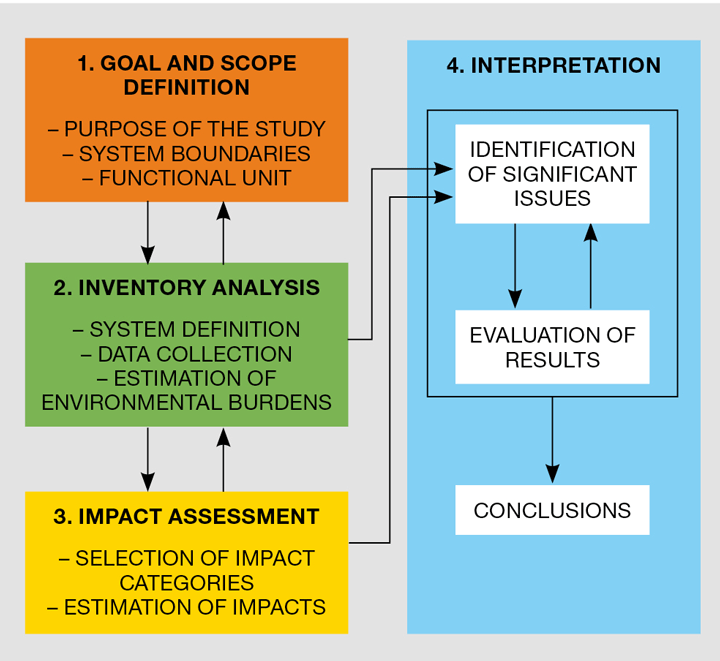

To be able to source the very best data for the ecological impacts of this, the ever-improving technique of life cycle analysis (LCA) may be applied, see Box 2.

Box 2: What is life cycle analysis?

Life cycle analysis (LCA) is a technique that assesses the environmental impacts associated with all the stages of the life of a product from mining of the raw material (eg iron ore), extraction through industrial processing (eg crushing, reducing, alloying, forming), manufacture, distribution, use in service, repair and maintenance, and, at the end of life, disposal or recycling. This technique, first applied in the 1960s, has become increasingly robust through ISO 14040/44 standards and the internationally-validated impact assessment data and methods that have emerged from ever improving science of emission pathways, toxicology and the effects of pollution on receptors.

LCA is increasingly used to determine government policies and legislation and is also in widespread use by companies. Firms are applying LCA to critique and compare the impact of both products and overall organisation, versus that of their competitors, and to identify "hot spots" in their operations where their ecological credentials can be improved.

The EU is very much taking a lead on LCA. It published the International Reference Life Cycle Data System (ILCD) Handbook in 2010 and recommends common methods for Product and Organisation Environmental Footprints (PEF & OEF) with the aim to build a level playing field and single market for green products.

Using the EU’s internationally-recognised guidance on data and methods allows the user to determine the most credible and widely-accepted view of the relative ecological impacts of using hydrogen versus other technologies over the 30/80-year "system lifetime" that is described above.

Could we adapt existing fossil fuel pipelines and chemical industry systems?

As mentioned earlier in this article, substantial savings in cost, delivery time and embedded carbon emissions could be made if it were possible to migrate some existing systems over to renewable use rather than scrapping and writing-off the value of existing assets to build new.

Studies already looking at injecting H2 to existing pipe networks, including HyDeploy and HyNet in the UK, start to bring into focus questions as to whether it would be possible to repurpose other existing systems to hydrogen:

- If hydrogen were to be generated at offshore wind, wave or tidal farms, could use of redundant undersea oil and gas lines be a competitive alternative to laying new electric cables?

- Could adapting pipeline systems, routes and depots that currently deliver energy as fossil fuels over to hydrogen be the fastest or least intrusive way to deliver low carbon energy? As the geographical location of our energy needs will probably remain similar, hydrogen pipelines may be able to use existing easements and adopt the same routes that currently deliver energy as fossil fuels to countrywide depots, even if the material or burial depth of the existing pipe is found not suitable for the new service. The depots might then be repurposed with fuel cells to convert the hydrogen to the electricity that their local populated areas need.

- Could energy storage could be introduced to the energy grid through salt cavities being converted to store hydrogen instead of natural gas?

If repurposing existing pipelines and salt cavities are found to be feasible, the cost and ecological impact of such refurbishment can be fed into the assessments of the energy systems functions 3, 4 and 5 listed earlier.

By setting out a programme of pipeline assessment and repurposing or reusing previous fossil fuel routes or depots it might then be possible to undertake stepwise, system-by-system, and region-by-region switchovers from fossil fuel to low carbon energy source via hydrogen networks that complement and back up the electricity grid.

A vision for the future

Presently the world is locked into fossil fuels for its primary energy needs. The penalty for this, as has been said in countless contexts, has been rising levels of atmospheric CO₂ and associated weather and other degenerative changes. In order to wean the world off fossil and towards hydrogen as a better energy carrier, a cross-linked partnership of hydrogen and electricity is needed for the optimum pathway towards achieving both the security-affordability-sustainability "energy trilemma" and net zero carbon emissions.

Developing such knowledge and expertise has the potential to cultivate a new UK and export workstream for engineers, for instance, in the oil and gas industry, to migrate to ‘blue’ or ‘green’ hydrogen and create an exemplar of how engineers of all disciplines can work in partnership with their industry counterparts and life cycle analysis experts to point the way to achieving and sustaining net-zero carbon emissions in the UK.

This is the 17th article in a series discussing the challenges and opportunities of the hydrogen economy, developed in partnership with IChemE’s Clean Energy Special Interest Group. To read more from the series online, visit the series hub.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.