Golden Touch

Antimicrobial resistance is among the World Health Organization’s top ten global health threats. From her hospital lab, Nidhi Kapil tells Sam Baker about her award-winning research using gold nanoparticles to create antimicrobial surfaces

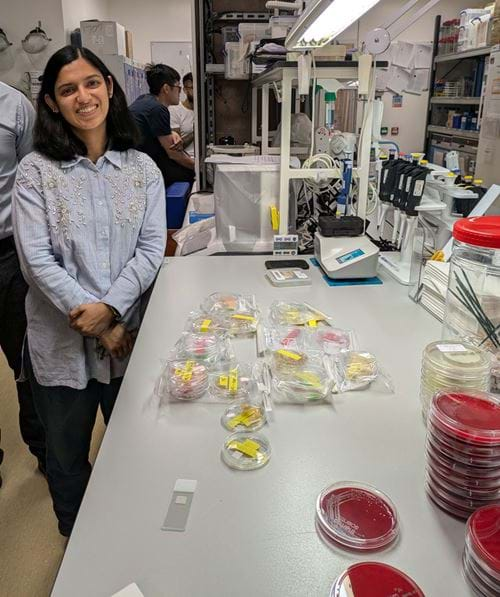

AT UNIVERSITY COLLEGE LONDON (UCL), chemical engineering postdoctoral researcher Nidhi Kapil is applying lessons from the Covid pandemic to help build greater resilience against future disease outbreaks.

For Kapil, antimicrobial resistance (AMR) is a “huge, huge problem”, and one whose effect on society “we have to learn from” as the Covid virus mutated to evade our efforts to suppress it. The consequences of a more deadly pathogen developing drug resistance don’t bear thinking about.

Kapil is not alone in her belief. The World Health Organization (WHO) designates AMR among its top ten threats to global health, warning that it “threatens to send us back to a time when we were unable to easily treat infections such as pneumonia, tuberculosis, gonorrhoea, and salmonellosis”. The threat is growing, largely due to the increasing abundance of human and veterinary antibiotics. Drug-resistant tuberculosis kills 1.6m people each year, and in 2017 around 600,000 cases of the disease were resistant to rifampicin, typically the most effective tuberculosis medicine.

Hospitals are notorious breeding grounds where microbes and antibiotics mix, creating ideal conditions for resistance to develop. Fighting AMR “requires an interdisciplinary approach”, says Kapil in which “microbiologists, engineers and clinicians all work together” to make hospitals more resilient to drug-resistant pathogens.

Catalysis for change

Kapil started life in STEM as a chemistry student in her native Punjab, India, graduating from Panjab University in 2014. After a research project at the Institute of Nano Science and Technology in Punjab, she switched to chemical engineering and moved to the UK in 2016 to start a PhD at UCL. She studied gold nanoparticles for catalysis and achieved her doctorate in 2021.

The move from catalysis to healthcare was self-driven. “I don’t think if I was working in a different area I could have just moved onto a different topic like this,” she says.

Kapil’s contribution to the fight against AMR is to design surfaces that can kill pathogens, neutralising drug-resistant germs before they enter a patient’s body. Catheters, for example, are a “very good source of infection for a patient”, Kapil says, so disease control could be enhanced by coating the instruments in antimicrobial surfaces.

Kapil’s team is developing the antimicrobial surfaces by embedding materials with gold nanoparticles. When exposed to light, these nanoparticles emit reactive oxygen species, giving the surfaces inherent antimicrobial properties. Kapil synthesises the surfaces in her lab at the main UCL campus in central London and characterises them according to the amount of gold nanoparticles they contain. She sends the samples to the microbiology lab at UCL Hospital, which hosts what she describes as a “rich library of multiple pathogens”. Microbiologists then test how well each surface kills bacteria, with future tests planned for fungi.

“The most important question is, how sustainable are they?” To that end, Kapil has run tests to measure how many times the surfaces can be reused before they become ineffective. She is pleased with the results. “The gold nanoparticles are very stable,” she says, adding: “They don’t leach out into the environment.” She aims to publish a full set of results in a paper in the coming months.

Kapil is hoping to test her designs on real hospital surfaces soon. The first application she and her team will look at is shower heads, a common environment for legionella to breed. “We want to start with the high priority pathogens and high priority surfaces, because it is not possible to replace everything yet.” If the shower heads are successful at killing bacteria, Kapil says she has “so many potential applications in mind”, including catheters, implants and even door handles.

It is an environment in which Kapil is familiar. Around a year after finishing her PhD, Kapil put her career on hold when her daughter was born. Her local maternity ward at the time was at the Royal London Hospital, but she wasn’t concerned about giving birth in the kind of place where many of the drug-resistant pathogens that occupy her research are found. “We were in a better era [than when mothers were giving birth at the height of Covid]. I always thought that people who gave birth during Covid were exemplary.”

Kapil is often asked how cash-strapped hospitals could afford to coat their surfaces with gold, but she explains that the nanoparticles are actually inexpensive. “The most expensive step is the immobilisation step, not actually the gold nanoparticles – 1 cm2 of the antimicrobial surface costs us around 51p [to coat]”. There is also an optimum concentration of gold nanoparticles, above which they add no antimicrobial benefit.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.