Better Together

Enabling interoperation of process simulation software via CAPE-OPEN

HAVE you ever used rigorous unit operation models and/or a sophisticated physical property model from other providers than those offered standard in your process simulator? Are you interested in using rigorous tools & models for process design, monitoring or optimization? If yes, help us to make model integration easier, smarter, and better. Please participate in our survey.

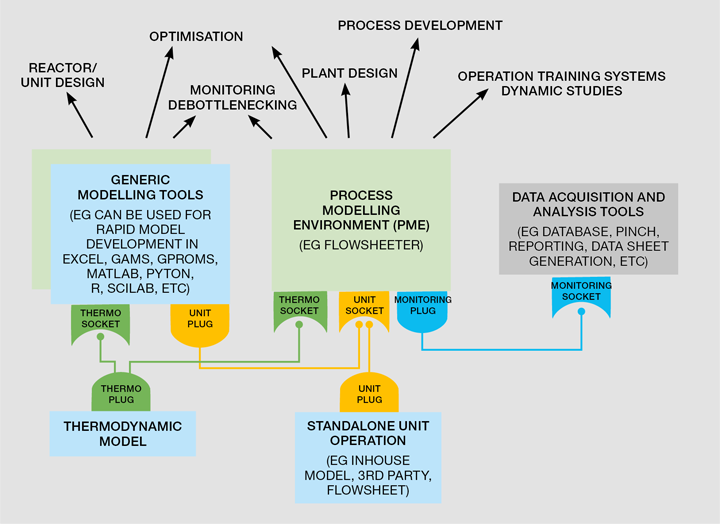

Almost 20 years after the first implementations in AspenPlus, HYSYS and gProms, CAPE-OPEN is now supported by virtually all mainstream flowsheet simulators. CAPE-OPEN is a standard that defines rules and interfaces that allow CAPE (computer-aided process engineering) applications or components to interoperate. Although not well known to most end users, CAPE-OPEN has enabled commercial, in-house and niche process model components to seamlessly interact with one another. The advantages of an open standard for simulation components should be evident:

- as a CAPE-OPEN unit operation, detailed equipment models can be plugged into any other CAPE-OPEN compliant flowsheet simulator, thereby saving on development and maintenance overheads;

- the same thermodynamic model can be used in two or more simulation environments. Even a simple cubic equation of state like Peng-Robinson comes in so many versions that calibrating it again in a new thermodynamic framework can be costly. Using CAPE-OPEN, your thermodynamic model can be re-used, enabling thermodynamic consistency between simulators; and

- the intellectual property, contained within key in-house unit operations, is protected when the unit operations are deployed within a process simulator as a CAPE-OPEN component. Modelled as CAPE-OPEN unit operations, they can be dropped into any other process simulator with CAPE-OPEN support.

In short, CAPE OPEN allows you to choose the best models to describe your process and to ensure consistency across simulation software from different vendors.

CAPE-OPEN Today

CO-LaN is the organisation which develops and maintains the CAPE-OPEN standards. It is a not-for-profit organisation managed by a group of operating companies (Air Liquide, BASF, BP, DOW, Linde, Shell). It has more than 100 associate members: software companies, academics and individuals. Associate membership is free-of-charge, though members can contribute by participating in special interest groups or providing licences for interoperability testing.

The application of CAPE-OPEN throughout the chemical process industry is difficult to determine. In 2015 van Baten & Pons collected all publicly-available information1. Their conclusion was clear: All major software vendors provide CAPE-OPEN interfaces, there are many cases published, and there is an impressive and steadily-growing list of scientific articles which refer to CAPE-OPEN. The extent of actual industrial or academic use, however, remains unclear, as CAPE-OPEN technology requires no licence or registration. This is one of the reasons why we have decided to conduct a survey and would like to invite you to help us to assess use and awareness of CAPE-OPEN.

There is another aspect to CO-LaN which I believe is unique. CO-LAN is one of the few organisations where IT experts, with a deep knowledge of chemical engineering, get to meet and exchange their experiences. The combination of different skills makes it an inspiring community which has impact beyond the actual commercial relevance of CAPE-OPEN. It's not surprising that academic packages like MOSAIC2 use CAPE-OPEN, and freeware packages like COCO are modelled around CAPE-OPEN and used in academic curricula3. The underlying structure of CAPE-OPEN, ie the decomposing of chemical engineering processes into units, thermodynamics and simulation environments, is natural and makes it easy for students to learn how to model chemical engineering processes.

CAPE-OPEN and digitalisation

In this current time of change, when digitalisation and open innovation are driving themes in many of our companies, I believe that CAPE-OPEN can play a more prominent role. With computational power on the rise, rigorous thermodynamics find more frequent application in statistical tools and in machine-learning based modeling. The choice of thermodynamic models should be driven by the best property package for the process under consideration, instead of what is available in the simulation software at hand. Interoperability via CAPE-OPEN is a logical choice.

Similarly, it becomes more and more important to bring together knowledge from different partners. The modular structure underlying CAPE-OPEN is a sound basis from which to develop and re-use software components. This enables an open collaboration where knowledge from different partners can easily be combined. Complex unit operations can be developed independently of the property package and flowsheet simulation software used. For a project involving multiple partners, CAPE-OPEN avoids the need to reveal sensitive IP.

Join the survey

In view of the increasingly rapid changes in software development and capability CO-LaN would like to collect a wide range of end-user opinions to help define its missions for the future. This is why we are reaching out to a larger community of process engineers with this CAPE-OPEN survey. The objective of our survey is two-fold. First, we want to assess the extent of knowledge of CAPE-OPEN outside our dedicated community; and, second, we would like to invite you to help steer our current and future activities and projects.

We encourage you to participate even if you are not familiar with the CAPE-OPEN standards. In particular we would like to:

- understand how you would prioritise the work on the CAPE-OPEN standards, ie amongst dynamic unit operations, equation-based units and flowsheeting, flowsheet monitoring specifications, numerical interfaces, reaction kinetic interfaces, etc;

- assess the acceptance and interest in a CAPE-OPEN certificate. A CAPE-OPEN certificate will provide quality assurance to interoperability between various software packages; and

- assess what simulations you envision in the future. This will help us to guide the developments, such as our new middleware, which facilitates the implementation of CAPE-OPEN on platforms like Windows, Linux and MacOS.

The survey is anonymous, and we are planning to publish the results on our website. To complete the survey please go to http://www.colan.org/survey/cape-open

The 15-20 min you spend in answering our questions are most valuable to us to make CAPE-OPEN better. Thank you.

References

1. van Baten, J, Pons, M, CAPE-OPEN: Interoperability in Industrial Flowsheet Simulation Software, Chem. Ing. Tech 2014, 86, No 7, 1-14

2. Tolksdorf, G,Esche, E, van Baten, JM, Wozny, G, Tailor-Made Modeling and Solution of Novel Process Units by Modular CAPE-OPEN-based Flowsheeting, Proceedings of the 26th European Symposium on Computer Aided Process Engineering (2016)

3. Möller, K., The use of CAPE-OPEN tools, COCO, Chemsep, in the teaching of undergraduate students at universities in southern Africa, Presented at the 2018 CAPE-OPEN Annual Conference, Ludwigshafen, Germany, October 2018

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.