A Short History of Unintended Consequences

In his ongoing series looking at the history of chemical engineering, Martin Pitt considers the harm that chemical engineers have contributed to and the lessons we should keep in mind

I WAS giving advice to school students when one told me he really liked chemistry, but he wouldn’t do it, or chemical engineering, for ethical reasons. This is not uncommon. The media treats the word chemical as a synonym for poison, and engineers as dirty polluters, with chemical plants as an explosion waiting to happen. As uncomfortable as this might be for us, there are precedents for this that we need to keep them in mind. Let’s review some of the most significant causes of these views.

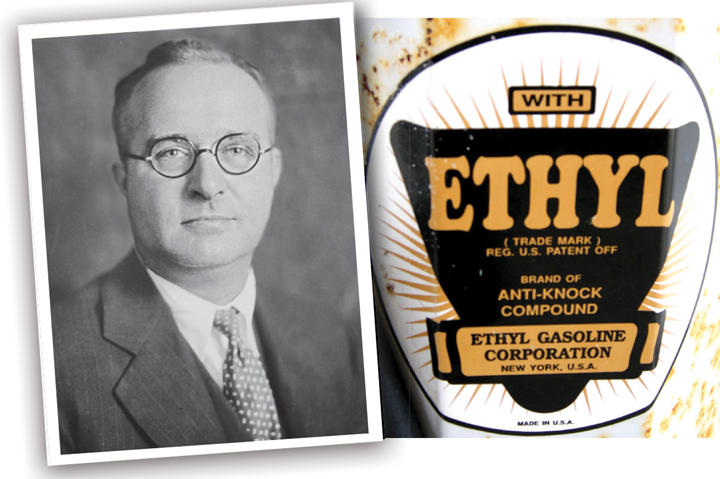

Lead in petrol – actually a bad idea

From many points of view, the addition of tetra-ethyl lead (TEL) to petrol was a great thing – a small amount of additive upgraded the octane rating of what came out of the basic process. It saved huge amounts of energy, was cheaper for the motorist, and turned a tidy profit. Chemical engineer Thomas Midgley Jr and his boss Charles Kettering patented it as an anti-knock agent in 1921. In 1923, the American Chemical Society (ACS) awarded Midgley a medal for this wonderful invention, the same year he had to take a long holiday to recover from lead poisoning.

The toxicity of lead was well known, so petrol containing the additive was branded “Ethyl” (customers might just possibly have supposed this was ethyl alcohol). At Dayton, Ohio in 1924, a leak of TEL at a refinery killed seven workers and many more had health problems as a consequence. People filling their cars would also inhale it. Midgley and the companies knew this, and public health professionals were ignored.

To stop the lead clogging and corroding valves and spark plugs, organohalogens were added to flush it out of the exhaust, creating an opportunity for absorption by people such as children, who had nothing to do with cars apart from being nearby. Being inventive, Midgley devised a way to get bromine, a halogen necessary for the additive, out of seawater for this purpose.

In 1935, a licence for TEL was given to IG Farben in Germany. The production enabled the Luftwaffe to achieve super-high performance with fuels well in excess of 100 octane in WW2.

The success of TEL and its hold on the market hindered the development of refining techniques, which have since created high octane lead-free petrol. However, once it was phased out, it was chemical engineers who created branched chain compounds giving higher octane, which they could have done many decades earlier.

Chlorofluorocarbons (CFCs) – not such a bad idea

Before replacement began many years ago, a leak from a large industrial refrigerated system posed immediate danger to human life. The refrigerant was either highly flammable gas or ammonia, which is toxic, and can also burn and explode, though less easily.

In 1930, Thomas Midgley Jr (again) came up with dichlorodifluoromethane, known commercially as Freon. Having decided to produce an alternative refrigerant, and having an idea of what would work chemically, it took him only three days to make this invention, instead of the years it had taken to find TEL by a similar route. Trained as a mechanical engineer, he became an inventive applied chemist, getting the highest award from the ACS and serving a term as president.

Freon and the variations we call CFCs were wonderful, compatible with seals and lubricants, and the only danger from a leak was suffocation. They also had low toxicity in occupational use.

We might still be using them if manufacturers seeking new markets had not put them in fire extinguishers, and of course in spray cans. In all of these they worked very well and vast amounts were used. Unlike refrigeration systems which are closed, these applications all vented into the environment. And so what? Non-toxic, non-flammable. No known hazard... but eventually the effect on the ozone layer was discovered, and they were progressively banned.

Later, supermarkets and domestic fridges boasted “environmentally friendly” refrigeration systems, meaning either the fire hazard of hydrocarbons or the toxic hazard of ammonia.

Freons have been hard to replace and many of the ozone-acceptable ones have created difficulty with equipment. While removing them from spray cans was correct, did we really need to ban them from closed industrial refrigeration systems where most could be collected for re-use?

Bhopal (1984) – Thousands killed by the worst chemical disaster

Did the people who planned and designed the Union Carbide pesticide plant in India have evil intent? Did Union Carbide not care about the risk to people around? Why were they making nasty pesticides anyway?

Let’s start with the last one.

India was losing a lot of food to pests. There were issues of overuse, but people were starving, so it was generally agreed that the pesticide would save lives and money. It could of course be imported, but by having it in India made it cheaper as well as providing employment and experience for chemical engineering to develop there. So, coming back to the first one, I would say good intent.

What about the engineers? It was built using essentially the same process as a Union Carbide plant in the US. Indians were entitled to the same level of safety as US workers. The first plant used methyl isocyanate (MIC) brought in by tanker, a definite risk during transport, and so in 1979 the process was modified to make it onsite – a safety improvement.

While hazard and operability (HAZOP) procedures were not yet around, they had clearly considered possible deviations, and installed several layers of protection. Even with HAZOP, what happened might well have been considered so unlikely it passed the risk test. Few engineers could have believed that the plant would end up in the state it did, with multiple safety systems off, understaffed, and with so many people living nearby. It was corporate and government action which turned a danger into one of the most disastrous gas leaks ever known.

Seveso (1976) – The famous environmental disaster

This was a disaster because the safety system worked exactly as it was supposed to in the process of making disinfectant. A decomposition started 50°C lower than lab tests suggested in a layer at the top of a reactor, after the stirrer had been turned off to comply with Italian law. The upper portion was heated by steam of an unexpectedly high temperature, and the resulting overpressure was vented, preventing an explosion of the reactor. The plant was not damaged and no one was killed.

However, it seems no thought had been given to the consequence of venting a caustic aerosol containing chlorocarbons. Dioxin is quoted as the bogeyman, but even without it, effects such as chloracne might well be expected from the reaction mixture. This had evidently not been considered when it should have been.

While no human was killed directly, animals were, and the health of many people was harmed. It showed how expensive the clean-up of an environmental release can be.

Prior to Bhopal and Seveso, the Flixborough explosion (1974) had already demonstrated that hazards could go beyond the plant.

Though these three in particular have given chemical engineering a bad press, it is notable how strongly the profession responded to each, with tremendous work being done to understand them in order to prevent recurrences. The IChemE and the AIChE both have large groups of unpaid volunteers involved in safety and loss prevention.

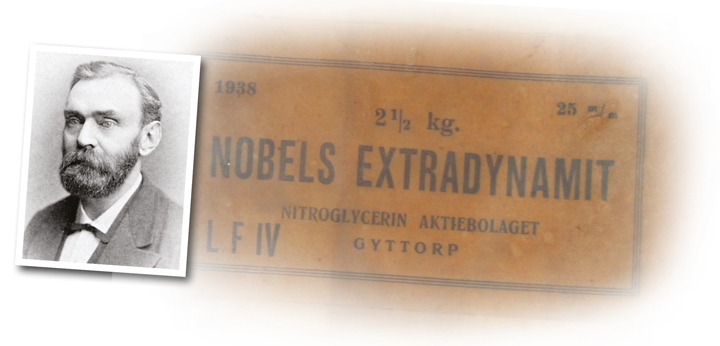

Explosives – A necessary evil?

It must be disconcerting to read your own obituary. Because of a newspaper error, Alfred Nobel got to read his, and was even more shocked at the title: “Merchant of Death is Dead”. As the inventor of dynamite, his legacy was to be known for profiting from killing people. This is why he established the Nobel Prizes, including one for peace, hoping to be remembered differently.

The founding fathers of IChemE contained many who had worked for or with the UK Ministry of Munitions, designing plants for the production of explosive materials in unprecedented amounts. Were they (and Nobel) bad people? Should we be ashamed of the damage they facilitated? Should chemical engineers refuse to have anything to do with explosives production?

Nobel invented dynamite and later gelignite as safer methods of using nitroglycerin in quarrying and mining. They were invented to reduce accidents and costs – surely a noble aim. These are still their major use today. Vast amounts of rock are released by explosives to create civil infrastructure, and a great deal of chemical engineering processes start with fragments of mineral. The US uses two million tonnes of explosives a year for civilian purposes. Safer explosives are one contribution to the reduction of death at work and a better life for all.

As to their use in war: engineers of all sorts may feel it is justified to create instruments of death to defend or to deter. That is an individual judgment. But we cannot be blamed for the need to have explosives generally, and the chemical processes (including the Haber-Bosch process) involved.

Poison Gas – good intention?

Fritz Haber (of the Haber-Bosch ammonia process) actually invented gas warfare because he thought it would be more humane since most victims would recover. In addition, gas would not damage buildings and would disperse, removing the hazard of unexploded shells. He and a team studied the release and dispersion of chlorine, which Germany had in abundance because of its extensive chemical industry, and first used it in April 1914.

The popular picture is that poison gas was solely used by Germany, but this is not at all true.

Winston Churchill thought it was an excellent idea, and suggested its use in shells and bombs, so the British released chlorine against the Germans at the Battle of Loos in September of the same year. The French and Russians followed. The US came late to the war but had no hesitation in using poison gases. They even developed their own, Lewisite, also known as “The Dew of Death”, an organoarsenic compound they planned to spray from the air over German cities. The armistice came just before they were able to do this.

Phosgene was the next one to be used. Germany had the advantage, not only of supplies but they also trained people to know how to handle it. It was more lethal than chlorine, and the major cause of death from gas in the war.

Tear gas was closer to Haber’s idea, incapacitating troops, but rarely being lethal – of particular concern if an advance or change of wind brought your own troops in contact. Several were used by all parties. His ideal agent was eventually found to be mustard gas, which caused blindness that generally wore off, and had a lethal rate of only 1.5%.

Fritz Haber was treated as a hero after the first gas attacks, but his wife was so distraught that she committed suicide. He was afraid he would be arrested as a war criminal but since the Allies had also broken the Hague conventions banning the use of poison weapons, he was not. Instead, he received the Nobel Prize in chemistry for his ammonia synthesis.

Practice in using poison gases brought some good things. A major health problem for troops, hospitals, and ordinary people at this time was infestation by parasites such as lice, fleas, and bedbugs, as well as flies, cockroaches, rats, and mice. Hydrogen cyanide (HCN) was too light to be useful on the battlefield, but was developed in Germany for fumigation in 1917. Rooms were sealed up and ventilated afterwards. Hospital wards, clothes, bedding, and grain storage could be treated without the damage caused by steam.

Because HCN has very little odour, in 1920, German company Degussa produced a version with added acrid agent, the methyl ester of HCN, which was marketed as Cyklon, later Zyklon.

In 1923, a product called Zyklon B was developed. This was slow-release pellets, and thus safer to use. It took some time for the gas to build up to a lethal concentration and in addition, it had acrid chlorine and bromine to warn during application or after inadequate ventilation.

In Germany, there were many gas chambers constructed for this purpose with highly regulated procedures and trained staff. It was good for the company and good for public health. Californian farmers also found Zyklon B convenient and safer for their trees.

In 1941, the SS carried out experiments with fumigation chambers and discovered that Zyklon B was faster and easier than carbon monoxide for the extermination of Jews, Russian prisoners, and others in what is now called the Holocaust.

Poison gas created a unique horror in the public mind, and it has been little used in warfare since. Whether it is ethically worse than bullets, shrapnel, fire, and explosives is debatable. However, all sorts of materials and things made for non-military applications can be turned to war.

While chemical engineers have improved life immeasurably, we need to be mindful of the associations and unintended consequences of our work

So, what is the conclusion?

Powerful money-making institutions have often acted for their own profit while knowing the harm they risk (or even know to be certain) to ordinary people. This applies to financial institutions as well as the tobacco industry, and has certainly occurred in many other industries. In reacting to public alarm, politicians have not always made things better by quick, dramatic actions. While chemical engineers overall have improved human life immeasurably, we need to recognise the associations given above, and be mindful of the unintended consequences that can arise from the work we contribute to.

Read other articles in his history series: https://www.thechemicalengineer.com/tags/chemical-engineering-history

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.