X-energy and Cavendish given £3m to assess Hartlepool ‘gumball’ nuclear reactor

X-ENERGY and Cavendish Nuclear have been awarded £3.34m (US$4.24m) by the UK government to assess how domestic manufacturing could support the construction of a novel small pebble-bed nuclear reactor. The pair want to build 12 reactors in Hartlepool by the early 2030s to help decarbonise local industry.

The support comes through the Future Nuclear Enabling Fund which will help companies mature their technologies ahead of the government selecting which projects will help meet national targets for more nuclear generation.

X-energy and Cavendish Nuclear will match the funding and use the money to assess domestic manufacturing and supply chain opportunities. Kier Group, Sheffield Forgemasters, and the Nuclear Advanced Manufacturing Centre will help X-energy and Cavendish Nuclear complete the assessment. The partners want UK firms to receive 80% of the value of their Xe-100 reactor projects.

Mick Gornall, managing director of Cavendish Nuclear, said: “A fleet of Xe-100s can complement renewables by providing constant or flexible power and produce steam to decarbonise industry and manufacture hydrogen and synthetic transport fuels.”

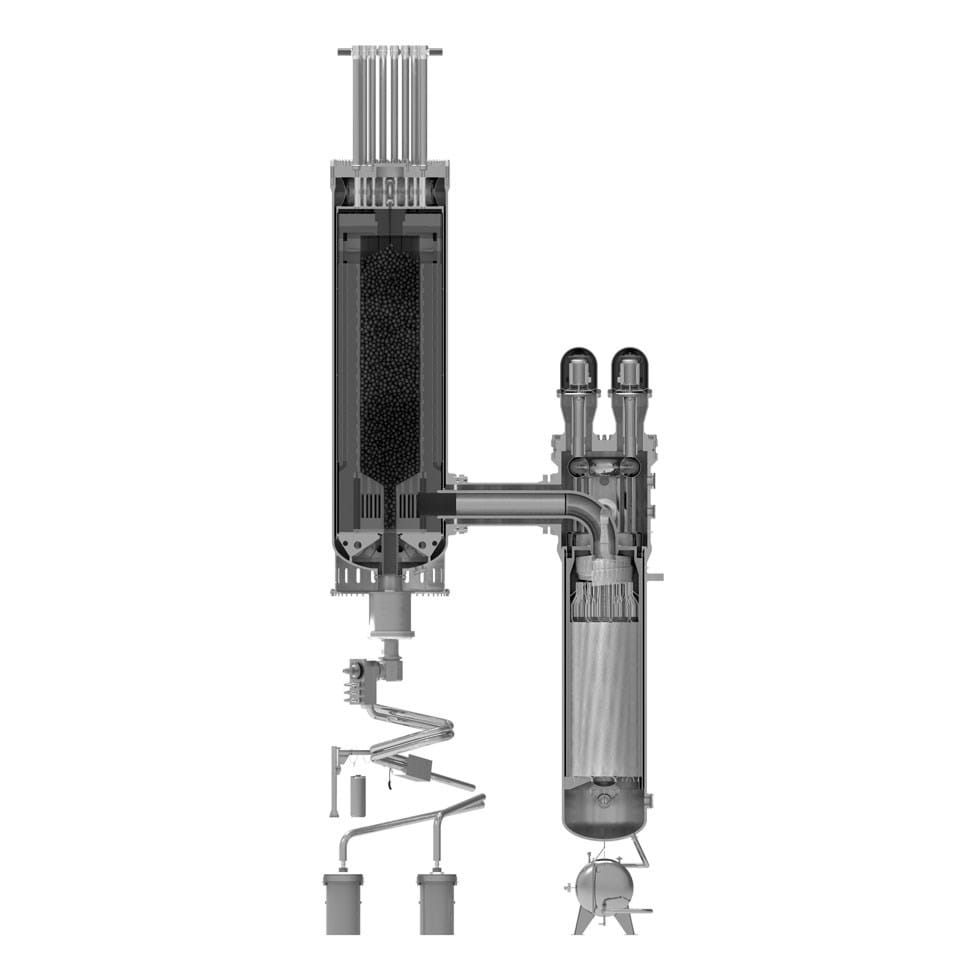

The Xe-100 is an 80 MWe high-temperature gas-cooled reactor design that is optimised to operate as a four-unit plant, delivering 320 MW of electric or 200 MW of heat. The reactor works like a gumball machine with new fuel pebbles the size of billiard balls fed into the top of the reactor to refresh the older ones ejected from the bottom. Each pebble remains in the core for around three years and is circulated through up to six times to achieve full burnup. Helium is cycled through the reactor to extract the heat into a steam generator.

The reactor design is currently being assessed by regulators in the US and Canada and the partners say they plan to engage with UK nuclear regulators to evaluate licensing approaches. In 2022, X-energy signed a letter of intent with Dow to install reactors at one of its US Gulf Coast chemical complexes, last year selecting its Seadrift manufacturing site in Texas. The installed reactors will provide power and steam to the chemicals manufacturing site, reducing CO2 emissions by an estimated 440,000 t/y.

Speaking in December about a report exploring how novel nuclear reactors could help decarbonise heavy industry, X-energy vice-president Carol Tansley, said: “This is a huge opportunity for Teesside and the country as a whole. There is a skilled nuclear workforce, with decades of experience of high temperature gas reactor technology, already in place at Hartlepool power station and the plant will be reaching the end of its life just as our project entered development and construction. We can provide high quality local jobs and the broadest range of decarbonisation options for the area’s industrial base, and then use that experience to benefit similar regions across the UK.”

Building on their plans for Hartlepool, X-energy and Cavendish Nuclear say they want to build as many as 40 Xe-100 reactors in the UK.

In February, Westinghouse Electric said it was developing plans for four small modular nuclear reactors near Stockton-on-Tees, which neighbours Hartlepool. It too would provide low carbon power for the region’s chemicals industry.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.