Technology package for carbon-neutral aviation fuel

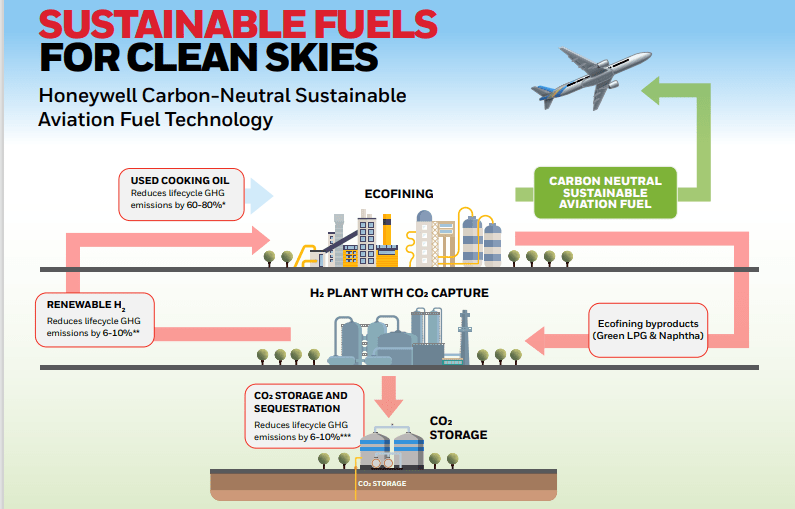

WOOD and technology company Honeywell have announced that they will combine green refining and hydrogen technologies, along with CO2 capture, into a package to support efforts for carbon-neutral aviation fuel.

The package will include the Ecofining process from Honeywell UOP, an international technology supplier and licensor. Ecofining technology can convert non-edible natural oils, animal fats, and other waste feedstocks into Honeywell Green Diesel and Honeywell Green Jet Fuel. Ben Owens, VP and General Manager of Honeywell Sustainable Technology Solutions, said that conversion is via a combination of hydrodeoxygenation (to remove oxygen), hydro-denitrification (to remove nitrogen), and isomerisation to improve cold flow properties of the fuel.

When using feedstock such as used cooking oil, the single-step process can offer up to 80% reduction in lifecycle greenhouse gas (GHG) emissions at this stage, compared to conventional petroleum jet fuel.

Owens said that renewable naphtha and liquid petroleum gas byproducts from Ecofining will be used to feed Wood’s technology to produce renewable hydrogen. He added that “renewable hydrogen produced in this manner can reduce lifecycle GHG emissions 6–10% when compared to the GHG emissions produced by conventional fossil hydrogen production”.

The renewable hydrogen produced can then be injected back into the Honeywell Ecofining process to remove impurities and create a cleaner burning renewable fuel.

Using Honeywell H2 Solutions, CO2 produced during hydrogen production can be captured and routed for permanent underground storage, offering an additional 10% reduction in emissions compared to conventional jet fuel. Honeywell H2 Solutions is a suite of carbon capture technologies that can be optimised for specific projects, including pressure swing adsorption, solvent, and cryogenic processes.

Owens said that as a result of combining these technologies, “a renewable fuels refinery can be essentially self-sustaining in hydrogen production while reducing the carbon intensity of the renewable fuels to very low levels”.

The package could support the US sustainable aviation fuel (SAF) Grand Challenge. The challenge is the result of a government-wide memorandum of understanding aiming to reduce costs, enhance sustainability, and expand production and use of SAF while achieving a minimum 50% lifecycle GHG emissions reduction. The initiative has a near-term goal of producing 3bn gallons/y (11.36bn L/y) of SAF by 2030. If the devised package were used to produce the 3bn gallons, 34m t/y of cumulative CO2 could be avoided, depending on the oil and fat feedstock mix used.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.