Picky porous electrodes take out toxins

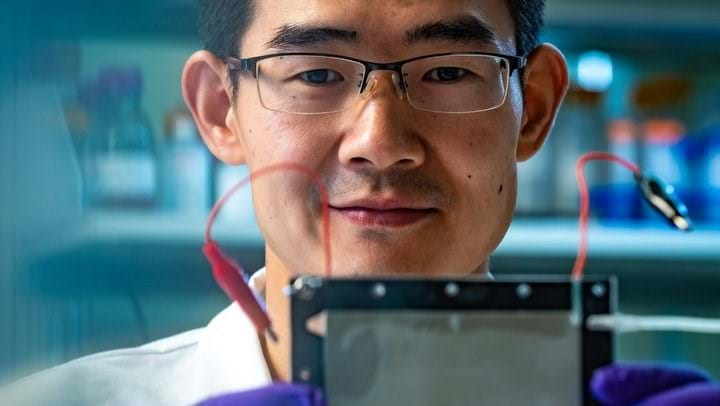

RESEARCHERS at Rice University, US, are developing a novel water treatment technology to selectively remove specific toxins from water through capacitive deionisation.

The system could potentially remove contaminants of choice from drinking water, and wastewater – for example from factories, sewage systems, and oil and gas wells.

"Traditional methods to remove everything, such as reverse osmosis, are expensive and energy intensive," said Qilin Li, professor of civil and environmental engineering and of materials science and nanoengineering, lead scientist, and co-author of the study. “If we figure out a way to just fish out these minor components, we can save a lot of energy.”

Li stated that the system is intended to work with current commercial water treatment systems. Kuichang Zuo, lead author of the paper and a postdoctoral researcher in Li's lab added that it could be possible to scale down the systems for in-home water use.

Selective removal

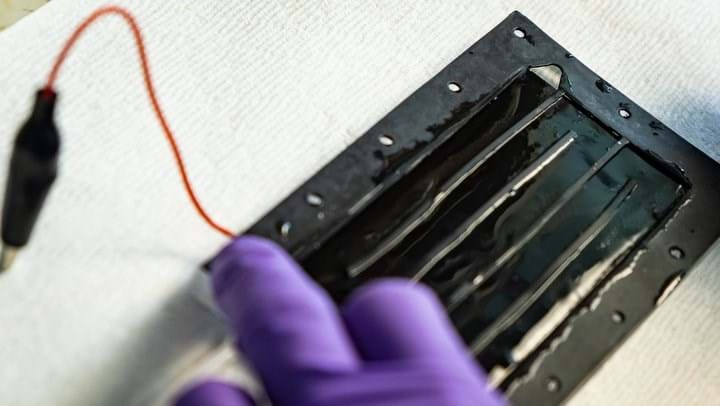

At the heart of this system lies a set of novel composite electrodes. The charged, porous electrodes selectively pull ions from fluids passing through a maze-like system, into pores. Once the pores are filled with toxins the electrodes can be cleaned and restored to their original capacity for reuse.

The key feature of this new technology is the selectivity. Li stated: “There are a lot of ions in water. Not everything is toxic. For example, sodium chloride (salt) is perfectly benign. We don't have to remove it unless the concentration gets too high.

“For many applications, we can leave non-hazardous ions behind, but there are certain ions that we need to remove.

“For example, in some drinking water wells, there's arsenic. In our drinking water pipes, there could be lead or copper. And in industrial applications, there are calcium and sulfate ions that form scale, a build-up of mineral deposits that foul and clog pipes.”

This novel water treatment would allow the removal of toxic and hazardous ions, whilst leaving benign ions behind.

Proof-of-principle system

The researchers developed a proof-of-principle system which was able to remove sulfate ions from water. Sulfate ions are scale-forming minerals that can give water a bitter taste and act as a laxative.

The electrodes in the system were coated with activated carbon, which was in turn coated with a thin film of tiny resin particles held together by quaternised polyvinyl alcohol. As sulfate-contaminated water flowed through a channel between charged electrodes, sulfate ions were attracted to the electrodes and passed through the resin coating to stick to the carbon.

Lab tests showed that the positively-charged coating on the cathode preferentially captured sulfate ions over salt at a ratio of 20:1.

The electrodes retained their properties for over 50 cycles. Though Zuo said “…in the lab, we've run the system for several hundred cycles and I don't see any breaking or peeling of the material."

The true merit

The success of the system with sulfate ions, however, is not the true merit of this research.

“The true merit of this work is not that we were able to selectively remove sulfate, because there are many other contaminants that are perhaps more important,” said Li. She continued: “the merit is that we developed a technology platform that we can use to target other contaminants as well by varying the composition of the electrode coating.”

The team is now developing coatings to attract other contaminants. They are also working with the University of Texas and Arizona State University on large-scale test systems.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.