New process improves efficiency of isobutanol production

RESEARCHERS have developed a new process for producing the biofuel isobutanol more economically.

Isobutanol is an alcohol that is a potential green alternative to gasoline. It has a high energy density and a low water solubility which reduces the risk of corrosion and is produced using biotechnology which has so far proven difficult. Biomass is fermented in a bioreactor using microorganisms, and the product is extracted with organic solvents which are often toxic and expensive. The process is also too slow to extract the isobutanol efficiently and this causes the fermentation to stop. To circumvent this, scientists have used more conventional techniques such as distillation and liquid extraction, but these methods are still not very successful.

A research team from several universities has developed a proof-of-concept process that makes isobutanol production more economical. They used supercritical carbon dioxide (scCO2) as a solvent and a bacterium that can thrive in the otherwise lethal conditions. scCO2 is abundant, renewable, non-flammable, non-hazardous, and inexpensive. Using the scCO2 allowed the isobutanol to be extracted at a rate that still allowed fermentation to take place. The process consumes around five times less energy than other extraction processes, and lowers the cost.

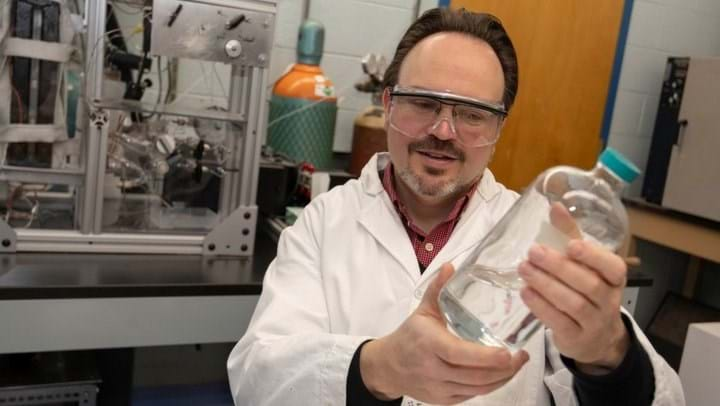

“The art of the research has been creating the extraction technique,” said Michael Timko, Associate Professor of chemical engineering at Worcester Polytechnic Institute in the US. “Virtually every way to separate mixtures had previously been tried on isobutanol, but we came up with the right process.”

The bacteria normally used to produce isobutanol can’t grow in scCO2 as the conditions are lethal. The team used a specific strain of Bacillus megaterium found inside a wellhead in Colorado that contains a deep subsurface reservoir of nearly pure CO2 at high pressure. The bacterium was then genetically engineered by adding the specific genes needed for the production of isobutanol.

“We used 30 years' worth of scientific experience to build this process,” said Timko. “Just having an organism that can grow in supercritical carbon dioxide isn’t much of a splash but producing isobutanol and being able to siphon it off at the right rate — all together that’s a big, big splash.”

Future work will involve further improving the process by getting the microbe to replicate faster, and improving the process would allow it to be demonstrated at a larger scale. “Think of Bacillus megaterium as a little chemical factory,” said Timko. “This chemical factory actually is self-replicating. The more effectively it can copy itself, the better it can produce a product. We need as many little microscopic factories as possible. This is the challenge researchers have been trying to overcome: How can we keep these little creatures alive long enough for them to generate the volume of isobutanol that we need?”

Nature Communications http://doi.org/gfzrms

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.