A BIOMASS pre-treatment technique could make biofuels cheaper, safer and up to 172% faster to produce, according to researchers.

Methane is a biofuel commonly used in electricity generation, and is produced by fermenting organic material such as agricultural or forestry waste. The composition of lignocellulosic biomass feedstock is complex, which limits the accessibility of biodegradable organics, meaning that the process can take between weeks and months to complete. Pre-treatment methods can be used to increase feedstock biodegradability, but these often incur challenges such as the formation of byproducts that inhibit microbial activity.

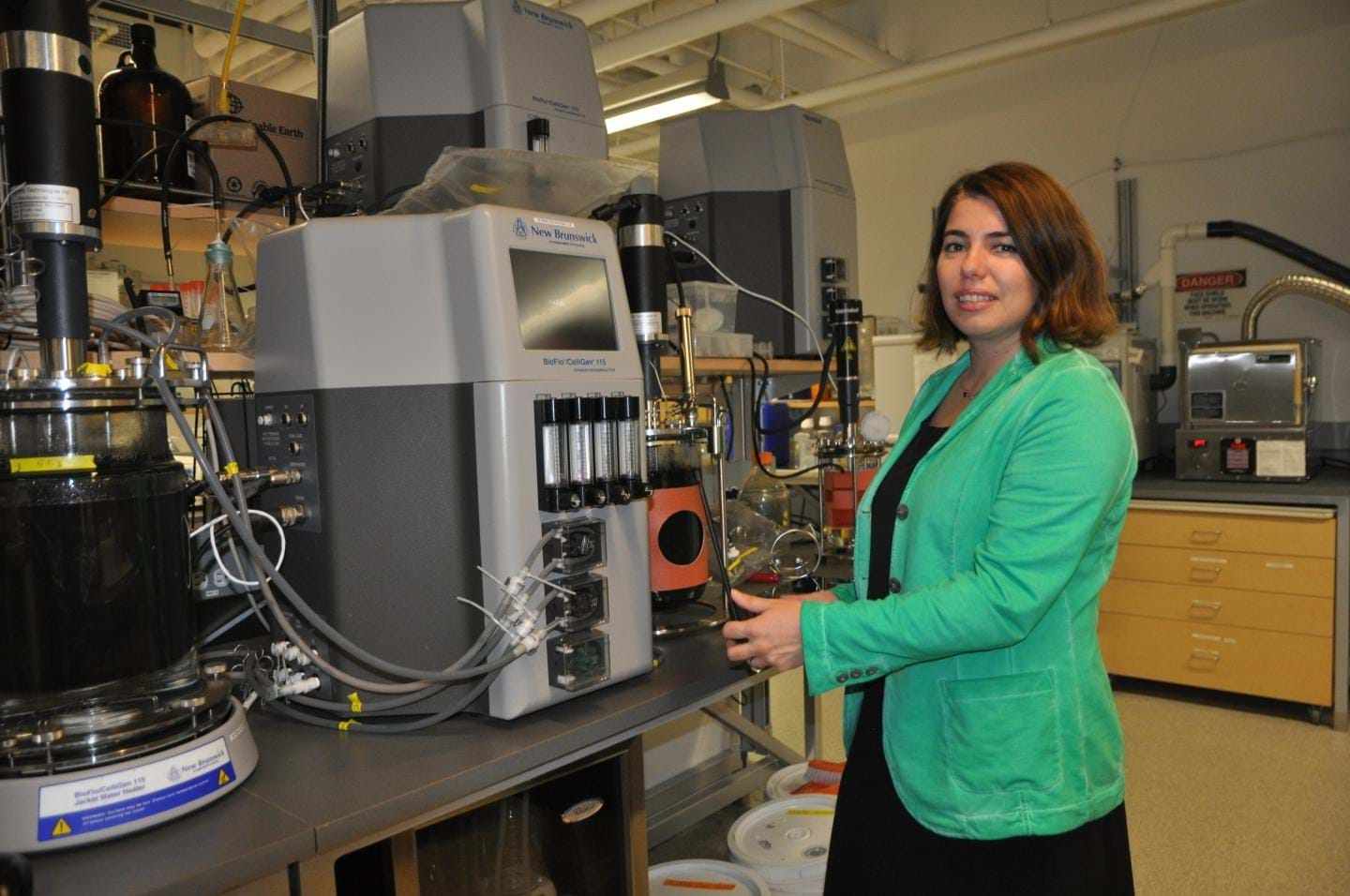

Now, researchers at the University of British Columbia, Canada, say they have developed a new hydrothermal pre-treatment technique that can cut biofuel production time without generating high levels of inhibitory compounds.

Although some hydrothermal pre-treatment techniques have already been commercialised, lead researcher Cigdem Eskicioglu explained how her group’s method is different. She said: “The difference is to pressurise the hydrothermal pre-treatment vessel with CO2 gas, and generate carbonic acid to act as a chemical pre-treatment – in addition to high temperature and pressure that hydrothermal pre-treatment provides. After this step, conventional anaerobic digestion and dark fermentation is applied.”

Pre-treatment of feedstocks was tested using temperatures and pressures of 26–175°C and 2.5–10.2 MPa respectively. The whole mixture was then fermented using a granular sludge inoculum, and was demonstrated to produce biogas 20–30% faster when using feedstocks of straws, sorghum and corn stover. In the case of Douglas fir bark, this was 172% faster, due to its highly refractory nature when not pre-treated. Further analysis of the pre-treated hydrolysate showed that furans and phenolic compounds were below the levels known to inhibit microbial activity.

The researchers have said that retrofitting existing bioreactors or building new miniaturised ones could be done cheaply and easily, as the method uses equipment and materials that are already widely available at an industrial scale.

Eskicioglu said: “The potential to more efficiently harness the energy from forestry waste products like tree bark can open a world of new opportunities. The new fermentation process would be relatively easy to implement on site and because the bioreactors could be much smaller, the costs could be kept low.”

The new technique may also make methane production safer.

“Unlike traditional biomass pre-treatment for bioreactors, our method doesn't require the use or generation of toxic chemicals. We still have some work to do to move it to an industrial scale, but our results so far are very promising,” Eskicioglu added.

The study will be published in September's edition of Water Research.