Keeping oil and water mixed for months

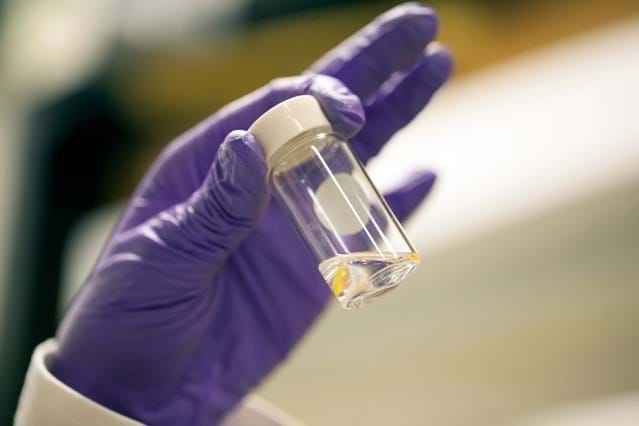

EMULSIONS that can stay stable for months have been created using a low-cost, low-energy process developed by US researchers.

Applications of the method, which can be applied to a range of oils and surfactants, could include drug delivery systems, cosmetics manufacture, and in food-processing.

The industrial production of emulsions typically involves “top-down” approaches, which rely either on the breakup of larger droplets or solvent exchange and inversion. However, conditions imposed by such techniques can often limit the materials used, and subsequent applications.

Now, researchers from MIT and the University of Illinois Chicago (UIC) have taken a new, “bottom up” approach, which involves initiating emulsion formation at the nano-scale.

They cool a bath of oil containing a small amount of surfactant, and then let water vapour from surrounding air condense onto the oil surface. This produces uniform water droplets, which can be controlled in size by changing the proportion of surfactant. The droplets then sink into the oil, and remain suspended for months, as they do not coalesce.

“The key to overcoming that separation is to have really small, nanoscale droplets,” said Ingrid Guha from MIT. “When the drops are small, gravity can’t overcome them, and they can remain suspended indefinitely.”

Their method is less energy-intensive than existing physical processes, and can be applied to a wide range of oils and surfactants. Guha added: “We envision that you could use multiple liquids and make much more complex emulsions.”

Resulting applications could include pharmaceuticals and food products, which are commonly limited by expiration dates as emulsions expire, or the oil and gas industry, where fluids sent down wells are often emulsions.

Sushant Anand, assistant professor at UIC, said: “Our bottom-up approach of creating nanoscale emulsions is highly scalable owing to the simplicity of the process.”

Nature Communications: http://doi.org/cf8b

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.