Ammonium nitrate explosion causes devastation in Beirut

Long-term unsafe storage suspected as likely cause

The explosion of 2,750 t of ammonium nitrate in Beirut, Lebanon, has injured at least 6,000 people and left 300,000 homeless. Reports vary on the number of dead, estimated to be between 178 and 220 at the time of going to press.

According to local media and video footage, the initial explosion occurred at around 18:00 local time on 4 August and caused white smoke to rise from a warehouse in Beirut port. This was followed by a huge second explosion which sent a shockwave out from the blast site. A pillar of reddish-brown smoke was seen rising from the site, the colour being characteristic of nitrogen dioxide.

The shockwave shattered windows as far away as Beirut International Airport, which is 9 km from the port, and significant damage was done to buildings near the port, including one hospital which had to shut shown and send patients elsewhere. The explosion created a 140 m wide crater, according to the BBC, and the damage to the city is estimated to be around US$15bn.

It has been reported that ammonium nitrate had been stored at a warehouse in the port since 2014 without any safety measures in place. The ammonium nitrate had been impounded from a ship that brought it into the port in 2013. According to a 2014 port authorities inspection report seen by The Financial Times, Lebanese officials knew that 1,950 of the 1 t bags were “torn”. Photos from 2015, also seen by The Financial Times, showed bags piled haphazardly on top of each other with ammonium nitrate spilling from the ripped bags. Anonymous sources told Reuters that the storage issue had been brought to the attention of “several committees and judges” and that an inspection team warned six months ago that the ammonium nitrate could “blow up all of Beirut”.

The exact cause of the explosion is still unknown. A source told Reuters that a fire started in warehouse 9 on the day of the explosion before spreading to warehouse 12, which housed the ammonium nitrate. According to The Wall Street Journal, Lebanese investigators said that welding to secure warehouse 12 was taking place on the day of the explosion.

Ammonium nitrate is primarily used for fertiliser. It is not explosive by itself but can cause explosions under certain conditions. Ken Patterson, of IChemE’s Loss Prevention Bulletin Editorial Panel, said: “Ammonium nitrate requires a significant igniter. The video evidence in Beirut showing the fire before the explosion, with fireworks apparently exploding all the time, would have provided an obvious source of ignition for the ammonium nitrate store.”

Geoffrey Maitland, Professor of Energy Engineering at Imperial College London, said: “[Ammonium nitrate] decomposes rapidly to gases, and because of the confinement, heat cannot escape, the gases rapidly expand, and the explosion occurs. This releases an enormous amount of energy, and sends out a shockwave as the surrounding air is rapidly compressed, which propagates very rapidly over the surrounding area and does enormous damage to buildings and people. This is what seems to have happened in Beirut.”

Maitland said that the long-term storage of the ammonium nitrate could also have made it susceptible to explosion. “For instance, if the storage was not airtight, in the humid conditions of Beirut, the salt could have taken up large quantities of water from the air which would cause the granules and pellets to fuse over time into a large consolidated mass from which heat and gases from the decomposition could not escape as easily as from a dispersed granular, free-flowing pile of fine particles. This would have just added to the confinement effect which increased the risk of an explosion once a source of heat was applied.”

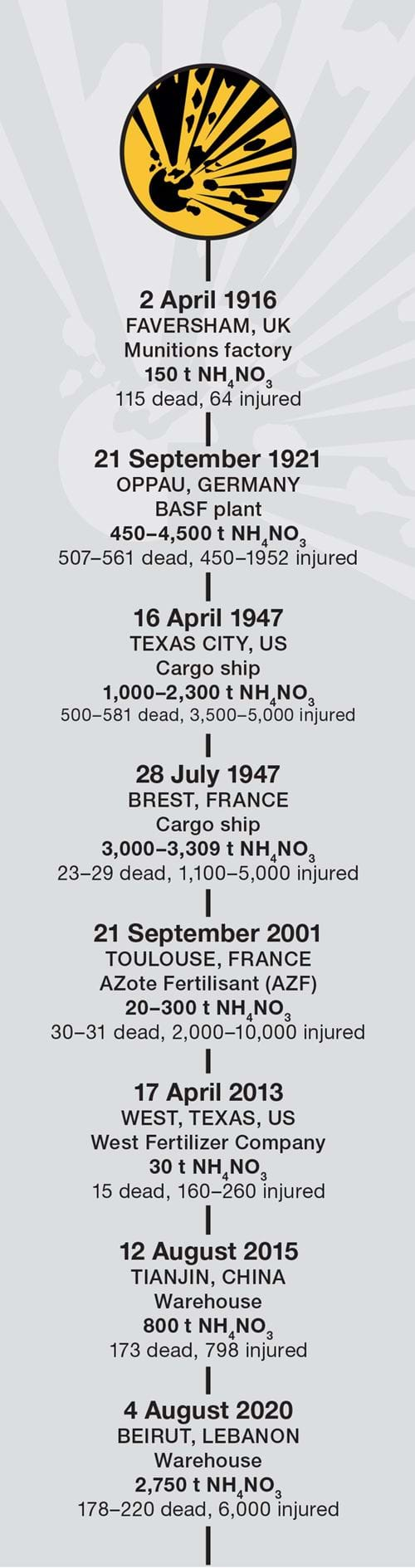

The dangers of ammonium nitrate storage have long been known. Numerous catastrophic explosions relating to ammonium nitrate have occurred since 1916. Some of these are highlighted in the timeline (opposite), although as with the Beirut explosion, the numbers differ depending on the source of information.

Trish Kerin, Director of the IChemE Safety Centre, said: “Tragically we have seen a massive explosion in Beirut, but even worse is that this is the latest in a long list of ammonium nitrate explosions that have occurred around the world. We must do better to learn the lessons of the past, those lessons are written in blood. This incident reminds us of the importance of process safety in our workplaces, including storage facilities. We must implement and manage the controls to prevent and mitigate the consequences.”

Wassim Naddi, a process safety and loss prevention engineer and HSE Manager at The Coral Oil Company, located 1.8 km from the blast site, described witnessing the explosion as horrifying. Naddi said that there were no strict regulations regarding ammonium nitrate storage in Lebanon and that there was a disregard for safety in the country. However, he is hopeful that things will now change. “Before [the explosion] we used to struggle to make people understand safety. Now that most of the people have unfortunately seen it with their own eyes, have lived it, and have luckily survived it, it will be easier to have this culture of change when it comes to safety. We hope a transparent investigation will answer lots of questions and aid in enforcing local and global prevention measures.”

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.