What to do About Waste?

Experts discuss future waste science policy

AT THE end of May, waste experts gathered together at Swansea University for the Royal Society of Chemistry’s (RSC’s) summit on future waste science policy.

The round-table discussion – organised by RSC’s Energy Sustainability and Environment Division (ESED) – brought together academics, industry experts, and representatives from government and trade associations to discuss science policy regarding future waste, with the aim of contributing knowledge and expertise to advise future government strategy. The day focussed on three specific areas:

- critical raw materials (CRMs) from waste electronic and electrical equipment (WEEE);

- plastics with a policy focus on bio-based plastics; and

- food and farming waste with a policy focus on anaerobic digestion (AD).

Critical raw materials from WEEE

Event chair Matthew Davies, Associate Professor at Swansea, introduced the global WEEE problem – the world’s fastest growing waste stream, currently generating around 50m t/y. Think discarded household appliances and consumer electronics, including that smartphone you recently replaced.

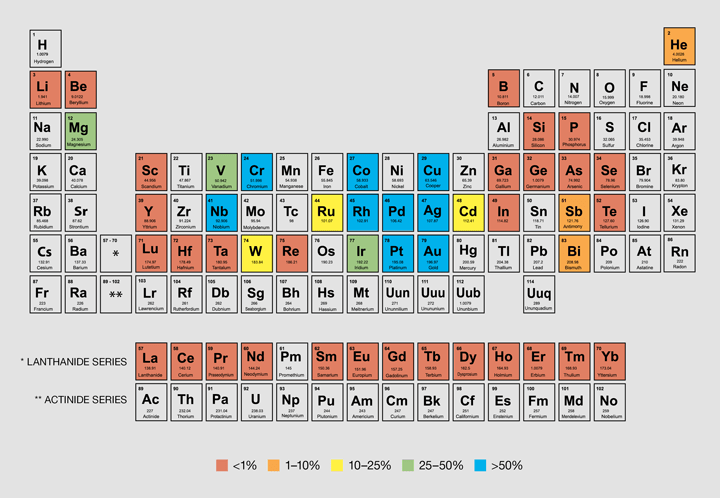

These items contain CRMs that are economically important but are at risk of short supply. Without them we could not produce solar panels or electric cars.

The concern is that some CRMs are being recycled at a rate of less than 1% (see below). Davies stressed that during the design phase of products, companies must consider how they can make CRMs recoverable, noting that this would allow them to market their products as being more sustainable.

Where re-use is happening, there are worries that electrical equipment is being shipped to countries with poor waste management standards. Tim Morris, Senior Waste Advisor for Natural Resources Wales said: “We need to track waste flows and look at all waste arisings. Policy providers are mainly concerned with municipal waste. However, this only amounts to 16%.” He added: “As a regulator, we seek better, smarter regulation that minimises the burdens for business, but does not compromise the protection of people or the environment. We will work with the waste sector to promote good practice, implement fair regulation, and achieve the [Welsh strategy document] ‘Towards Zero Waste’ aspirations.”

In 2018, RSC’s ESED looked at how to improve resource efficiency and waste management from end-of-life treatments of WEEE and how to avoid repeating mistakes when it comes to dealing with emerging technologies.

Rhys Charles, Researcher at Swansea, said the division discovered the main barriers are low collection rates of electronics; low recovery rates due to many CRMs not being targeted in recycling and recovery processes; and a poor adoption of circular economy principles in the design of electronic products and their life cycles.

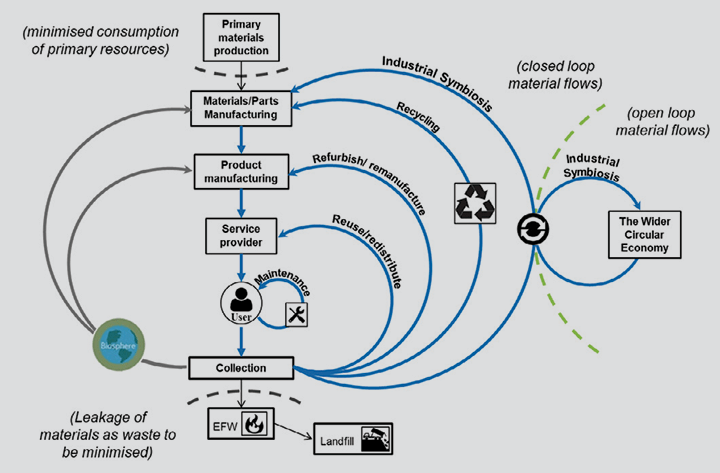

Gavin Bunting, Associate Professor at Swansea’s College of Engineering, and Chair of RCE Cymru’s Circular Economy Research and Innovation Group (CERIG) added: “If there is greater clarity around the different materials flows throughout the economy, opportunities for industrial symbiosis and implementation of the waste hierarchy can be achieved more successfully.”

Thoughts on future strategy

Charles explained that the current extended producer responsibility (EPR) for WEEE is not implemented in the best way to drive progress towards a circular economy and CRM recovery. At present we have a collective producer responsibility system, however an individual producer responsibility (IPR) based system would be more effective.

He would like to see future initiatives that replace mass-based targets with environmentally-weighted ones, financial incentives for use of recovered CRMs by industry, and adoption of a national waste tracking system for WEEE.

Andy Rees, Head of Waste Strategy for the Welsh Government reasoned that the way forward would also be to promote ethical sourcing and trading of materials; promoting longer life; EPR for WEEE; introducing refining of CRMs and valuable metals in the UK in addition to existing dismantling pre-processing operations ; and improving collection and separation – especially for small WEEE, including batteries.

Plastics and bio-based plastics

Clare Dyer-Smith, Programme Manager in the Research and Innovation team at the Royal Society of Chemistry, presented an overview of the RSC Materials Chemistry Division’s recent work on sustainable plastics (more detail here), and the contribution that chemistry can make to solve the plastic waste crisis. Examples of the role of chemistry in recycling plastics and in developing more sustainable plastics include:

- developing a greater understanding and optimisation of the depolymerisation process;

- development of separation methods to remove additives from plastics and aid recycling, or new/better additives so that the end-of-life consideration is built in from the beginning;

- understanding how plastics degrade both in a natural environment and in a chemical recycling facility; and

- incorporating lifecycle assessment into the design of products and in material choices.

An overarching message of the presentation is that any policy outcomes “need to be driven by evidence to ensure we are not fixing one aspect of the problem at the expense of the whole.”

The complexities of recycling

Keith Freegard, Associate Consultant at Axion Polymers, illustrated why recycling can be such a complex process.

Freegard said that during the product design stage, the technical people involved in creating a polymer compound are entirely focussed on delivering the material's functional performance for the working lifetime of the manufactured item. Little thought goes into end-of-life materials recovery. Using a broken plastic chair as an example, its components (the chemical ingredients of the polymer compound formulation) included polypropylene, a colour pigment, and calcium carbonate, which is hazardous in powder form. The chair seat moulding also contained an antioxidant which was permissible to use 15 years ago (but not today), a UV stabiliser found on REACH’s substance of very high concern (SVHC) list and a (now banned) brominated flame retardant under POPs (persistent organic pollutants). You can quickly begin to understand that recycling products is not as simple as it sounds.

He stressed that regulators need to focus on how to remove and separate chemicals at the end of life rather than banning them altogether, adding that we need to develop simpler polymers; risk assess the chemicals that are used; and introduce marking standards to identify SVHCs, using perhaps bright colours or luminous printing for ease of removal at end of life.

“Many of the polymers and additives used in plastics to enhance aesthetics and deliver beneficial functionality for the 'use-phase' become an issue for those who need to recycle these products at end of life, where highest value is associated with maximum purity of the recycled plastic. When products are sent for end-of-life treatment the ethos changes and it’s all about dismantling and material recovery. All the legacy additive chemicals are then viewed as unnecessary contaminants, which increases the complexity of recycling and reduces recyclate values and end markets.”

Regulators need to focus on how to remove chemicals at the end of life rather than banning them altogether

Policy landscape

Rees explained the policy landscape in Wales. The current target for Wales is to recycle 70% of its waste by 2025, ultimately aiming to becoming a zero-waste nation by 2050. Wales is, he said, leading the way in terms of plastic collection in the UK (see below).

Rees also discussed the complexities of recycling materials such as compostable PLA packaging which is a biodegradable thermoplastic made from renewable sources such as corn starch or sugarcane designed to substitute petroleum-based plastics. He highlighted that PLA plastics cannot be put in recycling bins; they do not break down in a home compost bin nor should they be placed in food waste bins – but that they must go to industrial compost facilities. PLA takes a long time to break down if littered and may decompose to methane if sent to landfill. He challenged the claim of whether PLAs can be deemed ‘compostable’ materials since “they add no value to the soil in terms of nutrients or fibre.”

He added: “The key to minimising the end-of-life impact and cost lies in the packaging design” and that “future designs should reduce product waste, use high-level of recycled content, have a minimum-to-no environmental impact if littered, and use labelling to specify how it should be recycled.”

Bunting supported this view, highlighting that the recent response by CERIG to the Consultation on reforming the UK packaging producer responsibility system, recommend that “encouraging reduction of packaging and supporting better packaging design, such as design for reusability and alternative lower environmental impact materials, should be an overarching primary principle”.

Food and farming waste (anaerobic digestion)

Approximately one third of the food produced globally for human consumption is lost or wasted every year. Figures from food waste charity WRAP reveal that the UK food industry wastes 1.9m t/y of food, of which 250,000 t is still edible – enough for 650m meals.

Rebecca Thompson, Senior Policy Manager at the Anaerobic Digestion and Bioresources Association (ADBA) discussed the role of AD in decarbonising food waste and agriculture. While agriculture is a difficult sector to decarbonise, AD can convert farm waste into biogas, producing saleable energy, while eliminating the emissions from degrading waste. AD also produces nutrient-rich digestate that can be sold as a fertiliser, reducing emissions from the production of artificial fertilisers.

7–10m t of food waste streams could be diverted to AD as a result of England’s resource and waste strategy which positions AD as the “best environmental outcome for food waste,” said Thompson. Plant capacity will increase progressively as collection rates increase and there is a vast potential to increase gas and energy production, draw new investments, create new jobs and produce more nutrient-rich digestate.

Rees highlighted that some of the issues regarding AD relate to optimising biogas production; minimising the fugitive release of methane and ammonia; maximising nutrients recycling back to the soil; including food-contaminated kitchen roll fibre in feedstock; and eliminating plastic particles in the digestate.

He explained that the focus for Wales regarding food waste is to prevent it where possible from the beginning; collect it separately and use it for AD; and explore opportunities for converting food waste into biochemicals, materials and other forms of recycling.

Tom Pye from the Department for Environment, Food and Rural Affairs (Defra) explained that England’s resources and waste strategy links back to the 25-year environment plan where the Government pledged to leave the environment in a better condition for the next generation. The plan seeks to address waste crime, food wastes, and product lifecycles. He said, “a circular economy will see us keeping resources in use as long as possible in order to gain maximum value from them.”

Pye called for stakeholders to support the strategy by responding to consultations; applying for relevant innovation funding; and addressing the gaps in the areas of research interest to accelerate the development of a circular economy in the UK.

Conclusions

Asked what he thought was the most important outcome of the day, Freegard said: “One of the key points of recognition was that while we’ve spent the last 25–30 years creating new polymer molecules and modifying material properties via chemical additive compounding, we now need to shift our focus to learn about the reverse of these processes and how to de-construct complex molecules and macrostructures inside plastics.”

On the issue of chemical engineers working with others at cross-disciplinary boundaries to solve global challenges, Freegard said: “It is very important, especially in our move from a linear to a more circular economy. In the last 3–4 years there has been a greater willingness among different people along the circular supply chain to collaborate effectively and consider implications for products at the end of life.

“Gradually the leading organisations in sustainable manufacturing sectors are beginning to incorporate circulatory principles at the product design stage and that is key for future output yields in advanced waste resource sorting plants. Plastics packaging is leading this change process for obvious reasons, but electrical, automotive and construction sectors will be forced to follow down this route of transition to a sustainable use of materials in the near future.”

Camilla Alexander-White, Senior Policy Advisor at the RSC, said “We hope this is an area where RSC and IChemE can continue to share ideas and work together, as collaboration between chemical scientists and chemical engineers is critical in delivering solutions for future waste and a circular economy. This workshop has provided good evidence to share with policymakers as the resources and waste strategies involve all the UK’s devolved nations”.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.