Rules of Thumb: Process Control Valves

Stephen Hall discusses the golden rules for design

CONTROL valves are used to control several important process parameters: flow rate, level, temperature, pressure, and composition. This month I am discussing rules of thumb that engineers use to select and size control valves. Some of these rules are fuzzy, and applying alternative rules may lead to conflicting answers. You can often resolve those conflicts by understanding the reasoning behind the rules and assessing how your individual problem fits.

Rules of thumb should only be used for preliminary valve selection and to reality-check submittals from vendors. Control valves are expensive high-tech products. The final selection and design should be left to experts, such as the valve manufacturer’s engineers, who can perform a complete system analysis that includes considerations for the control range, control accuracy, deadband, response time, noise, cavitation, etc. But engineers with a basic understanding can ask intelligent questions, ensure that appropriate calculations were performed by the experts, and challenge vendors to adhere to reasonable performance requirements.

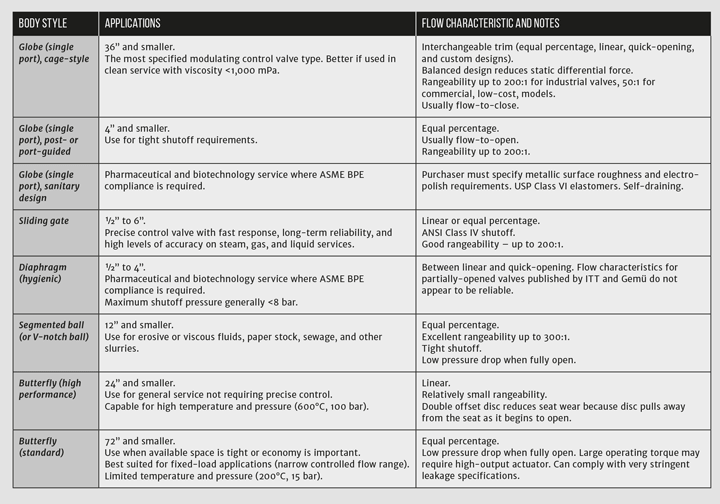

The most common types of control valves are listed in Table 1.

The first step in sizing a valve is to specify the flow rates and pressure drops at the high and low extents of the control range. Engineers often make the mistake of specifying a wider range than is necessary, thinking that this gives a conservative cushion in the sizing. When coupled with other conservative assumptions and calculations, an oversized valve is supplied, which results in suboptimal control because valves are usually most responsive when they operate closer to the fully open position (60-80% open). If you can dictate the pressure drop through the valve, use 20% of the total system pressure drop or 10 psi (0.7 bar), whichever is greater.

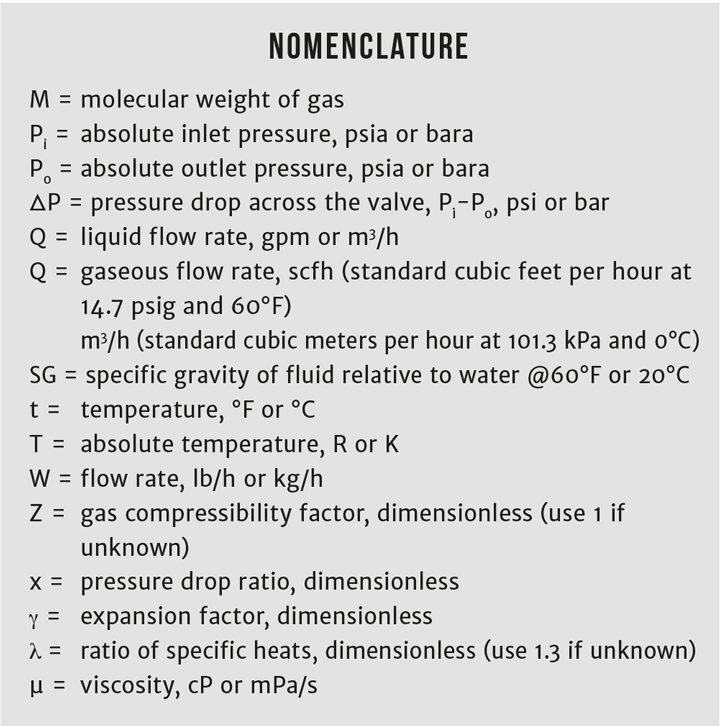

Refer to the Nomenclature boxout for variables definitions for the following calculations.

Non-compressible fluid (liquid)

Calculate the required flow coefficients at the high (Cvhigh) and low (Cvlow) conditions using this simplified formula (for liquids, non-compressible):

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.