Toyota magnet cuts need for rare earth elements

TOYOTA has developed a new magnet for electric car motors that requires less neodymium than conventional magnets.

Neodymium (Nd) is a rare earth element that is used in the magnets needed to keep the motors turning in electric vehicles. The Nd magnets can stay magnetised for a long time and resist temperatures of up to 100oC. However, with the increasing number of electric vehicles being produced, there are concerns that shortages of Nd will become a problem, which has prompted Toyota to develop a new type of Nd magnet.

Around 30% of the elements used in magnets are rare earths, due to their resistance to demagnetisation, which is known as high coercivity. Terbium (Tb) and dysprosium (Dy), also rare earths, are typically added to Nd magnets to increase the coercivity and heat resistance. Tb and Dy are expensive and not very abundant, but Toyota’s new magnet negates the need for these elements altogether, while reducing the amount of Nd needed.

Toyota’s technique is threefold; it reduces the grain sizes within the magnet, creates layering on the grain surface, and introduces lanthanum (La) and cerium (Ce) into the grain.

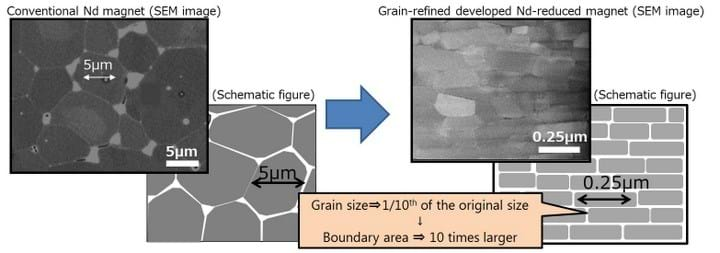

The microcrystalline grains which make up rare earth magnets are reduced to less than 10% of the size of the grains in conventional magnets, while also increasing the boundary area of the grain. This helps to retain the high coercivity at high temperatures.

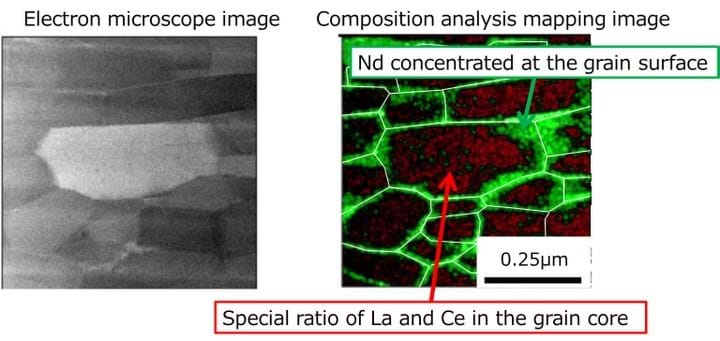

In conventional magnets, the Nd is homogeneous throughout the grain. In the new magnet, Nd is concentrated as a layer on the surface of the grain and reduced in the interior. This maintains the high coercivity while reducing the amount of Nd needed.

Td and Dy are replaced by the more abundant, and cheaper, rare earths La and Ce. These cannot simply be alloyed with Nd, as this would result is a loss of performance. However, when La and Ce are in a specific ratio of 1:3 within the core of the grain, the performance is maintained.

The new Nd-reduced, heat-resistant magnet will be useful in robotics as well as electric vehicles and will also help to maintain the balance of supply and demand for valuable rare earth resources. Toyota is continuing to enhance the technology and expect it to come into use during the first half of the 2020s.

Recent Editions

Catch up on the latest news, views and jobs from The Chemical Engineer. Below are the four latest issues. View a wider selection of the archive from within the Magazine section of this site.